Smart polymers are materials that change their properties, like shape, color, or permeability, in response to environmental stimuli such as temperature, pH, light, or chemicals. These adaptable materials are used in healthcare, electronics, and even construction to create responsive surfaces, targeted drug delivery, or self-healing structures. Understanding how different stimuli trigger these responses helps release innovative applications. Keep exploring to discover how these dynamic materials are transforming industries and opening new possibilities.

Key Takeaways

- Smart polymers are materials that change their properties (shape, color, permeability) in response to environmental stimuli like temperature, pH, light, or chemicals.

- They contain cross-linked networks enabling reversible or irreversible shape and property alterations triggered by specific external signals.

- These materials are used in applications such as targeted drug delivery, self-healing coatings, sensors, and adaptive textiles.

- Their responsiveness allows for precise control in industries like healthcare, electronics, automotive, construction, and consumer goods.

- Challenges include developing reliable, scalable synthesis methods and ensuring consistent, reversible responses for practical applications.

Types of Stimuli That Trigger Smart Polymer Responses

Smart polymers respond to a variety of external stimuli that can trigger their unique behaviors. Temperature changes are common, with polymers like PNIPAAm exhibiting LCST behavior—becoming insoluble or shrinking above specific thresholds. This process is reversible, making them ideal for drug delivery systems that respond to body temperature. Many temperature-sensitive polymers can also be engineered to have precise transition points to match specific biomedical applications.

pH variations cause ionizable groups to protonate or deprotonate, altering solubility and swelling. These changes are useful in targeted drug release or water purification. Enzymatic activity or oxidative conditions can also serve as chemical stimuli, enabling smart polymers to respond to biological environments.

Light-responsive polymers incorporate chromophores like azobenzene, changing shape under UV or visible light. This enables remote control of their properties. Light-sensitive polymers are used in optical data storage and actuators, expanding their functional applications.

Chemical stimuli, such as redox conditions or enzyme interactions, induce swelling or degradation. These features are applicable in sensors and self-healing materials. Some smart polymers respond to multiple stimuli simultaneously, providing precise control for advanced biomedical and industrial applications.

Key Features and Characteristics of Smart Polymers

The key features of smart polymers revolve around their highly predictable and uniform responses to environmental stimuli, which cause significant changes in properties such as shape, color, or permeability throughout the material. They respond to even slight environmental variations, triggering macroscale changes organized at the molecular level. These polymers contain cross-linked networks of long, entangled chains that enable reversible or irreversible property shifts. Their structure can be tailored for specific functions, including shape memory and tunable mechanical properties. Many exhibit reversible responses, returning to their original state after stimulus removal, while others undergo permanent changes. Designed for stability over multiple cycles, they can respond rapidly or gradually depending on the stimulus. Their ability to respond dramatically to small environmental variations makes them particularly useful in various adaptive applications. Biocompatibility and tunability make smart polymers versatile, suitable for diverse applications requiring precise, adaptive behavior.

Diverse Applications Transforming Industries

Diverse industries are harnessing the unique capabilities of smart polymers to revolutionize their products and processes. In healthcare, they enable targeted drug delivery, support tissue regeneration, and improve gene therapy. Diagnostic sensors and reversible biocatalysts benefit from their responsiveness and biocompatibility. Advancements in biomedical applications are expanding the scope of smart polymers, allowing for more sophisticated and minimally invasive treatments. Additionally, ongoing research into biocompatible materials continues to open new avenues for their integration into medical devices and implants.

In automotive, smart polymers reduce weight, offer self-healing coatings, and enhance safety through real-time structural monitoring. They also provide adaptive components that respond to environmental changes.

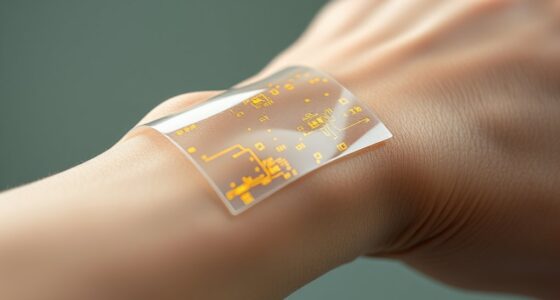

The electronics industry relies on smart polymers for flexible devices, sensors, and responsive coatings that modify properties with stimuli.

Construction uses them for self-healing concrete, smart insulation, and adaptive windows, extending durability.

In textiles, smart polymers create responsive fabrics, shape-memory fibers, and embedded wearable electronics, improving comfort, functionality, and health monitoring in everyday life.

Market Growth and Emerging Trends in Smart Polymer Technologies

As the smart polymer market continues to grow, innovative trends are shaping its future across multiple industries. The market was valued at roughly USD 3.41–12.84 billion in 2023 and is projected to reach USD 10.44 billion by 2032, with a CAGR of 13.2%. In 2024, it hit nearly USD 5.41 billion, growing at 9.51%. Emerging trends include personalized medicine, electronics, consumer goods, biodegradable options, and smart coatings. These advancements are driven by increased research, regional investment, and international collaborations. Signs of spoilage in materials or products can influence consumer trust and safety standards in smart polymers.

| Trend | Industry Focus | Impact |

|---|---|---|

| Personalized Medicine | Healthcare | Custom drug delivery |

| Electronics & Sensors | Tech | Flexible devices, sensors |

| Consumer Goods | Apparel, Home | Adaptive clothing, self-cleaning surfaces |

| Biodegradable Materials | Sustainability | Eco-friendly waste reduction |

| Smart Coatings | Biomedical, Environment | Responsive protective layers |

Challenges and Future Prospects in Smart Polymer Development

Developing smart polymers presents significant challenges, particularly in synthesizing complex molecular structures that respond reliably to stimuli like temperature or pH. You need intricate designs, which makes synthesis difficult, and current computational tools are still evolving, complicating modeling efforts. Advancements in computational modeling are crucial for predicting polymer behavior and accelerating development processes. Creating new monomers and refining copolymerization methods require extensive research to achieve desired properties. Reversibility of responses is essential for cyclic applications but can be inconsistent, affecting functionality. Scaling up production while maintaining responsiveness presents industrial hurdles. Efficient writing techniques can help streamline research documentation and testing procedures, ultimately speeding up development. Looking ahead, biomedical uses like targeted drug delivery, tissue engineering, and bioresponsive implants hold promise. Environmental applications such as pollution control and water treatment also benefit from smart polymers. However, ensuring recyclability, biodegradability, and cost-effectiveness remains a challenge for sustainable development in this field.

Frequently Asked Questions

How Are Smart Polymers Synthesized and What Are Common Production Methods?

You can synthesize smart polymers using various methods. Free radical polymerization is popular for its simplicity, while controlled radical polymerization offers better structure control. Click chemistry provides high efficiency, and grafting techniques modify existing polymers for responsiveness. Ring-opening polymerization creates precise architectures.

To make production greener, you should consider using metal-free or less toxic catalysts, one-step processes, green solvents, and focus on biodegradable, environmentally friendly materials.

What Are the Safety and Environmental Concerns Related to Smart Polymer Usage?

Imagine a smart polymer used in medical implants that releases toxins if it degrades prematurely. You should be aware of safety concerns like toxicity from byproducts and physical hazards from unexpected transformations.

Environmentally, improper disposal could harm ecosystems, and resource-intensive production impacts sustainability. To address these issues, strict regulations, eco-friendly materials, and thorough impact assessments are crucial to guarantee safe, responsible use of smart polymers.

Can Smart Polymers Be Customized for Specific Environmental Triggers or Conditions?

You can definitely customize smart polymers for specific environmental triggers or conditions. By adjusting their molecular structures and functional groups, you enable them to respond to stimuli like temperature, pH, or light.

This tailoring allows you to design materials that react precisely as needed, whether for drug delivery, environmental sensing, or other applications. Such customization enhances their versatility and effectiveness in various fields, making them highly adaptable to your specific environmental requirements.

How Do Smart Polymers Compare in Cost to Traditional Materials?

You’ll find that smart polymers are generally more expensive than traditional materials. Their production involves complex, costly processes and advanced technology, which drives up initial costs.

In contrast, traditional polymers benefit from economies of scale, simpler manufacturing, and lower raw material costs. This cost difference often makes smart polymers less attractive for price-sensitive projects, limiting their adoption despite their innovative capabilities.

What Are the Long-Term Stability and Aging Effects on Smart Polymers?

You should consider how long your smart polymers last and how they age over time. UV radiation, temperature, and humidity weaken their properties, causing molecular changes and physical aging like brittleness.

These effects can slow responsiveness and alter diffusion rates. To improve longevity, incorporate UV protectants and select materials with better stability.

Regular testing helps track degradation, ensuring your applications maintain performance despite environmental exposure.

Conclusion

As you explore smart polymers, remember they’re like chameleons, adapting to their surroundings. Their ability to respond symbolizes hope for innovative solutions across industries. Embrace their potential to revolutionize technology, medicine, and beyond. Just as nature’s resilience inspires us, these materials promise a future where adaptability and intelligence lead the way. By harnessing their power, you become part of a transformative journey—shaping a world that responds intuitively to its environment.