Self-healing polymers are materials that repair themselves automatically, similar to how your skin heals cuts and cracks. They contain embedded healing agents or dynamic bonds that activate when damage occurs, allowing the material to recover its strength and properties. This process helps extend the lifespan of products, reduce maintenance costs, and improve durability. To find out how these smart materials work and their future potential, keep exploring their fascinating mechanisms and uses.

Key Takeaways

- Self-healing polymers repair damage by activating embedded healing agents or reversible bonds, mimicking natural skin repair.

- They use microcapsules or dynamic chemical bonds that reform after breaking to restore material integrity.

- Damage triggers the release of healing agents or bond reformation, enabling the material to mend itself automatically.

- This process extends product lifespan, reduces maintenance, and enhances durability similar to how skin heals cuts.

- Advances include faster healing mechanisms and smart triggers like heat or light for more efficient self-repair.

Have you ever wondered how materials could repair themselves after damage? Imagine a world where cracks and tears in everyday objects, from smartphones to airplane wings, heal on their own without human intervention. This is the promise of self-healing polymers, advanced materials designed to mimic the natural repair process of human skin.

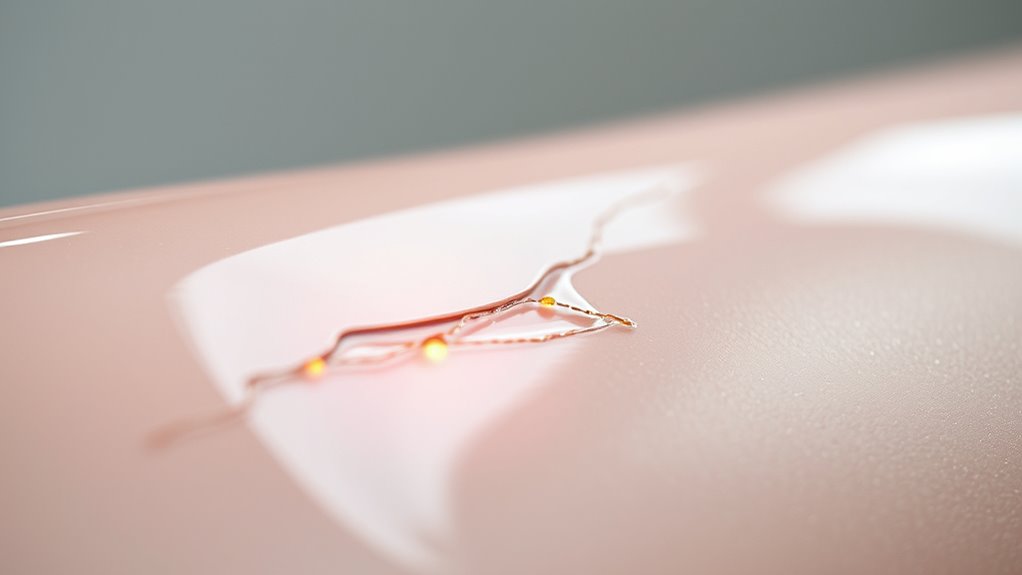

These polymers contain embedded healing agents or have dynamic chemical bonds that activate when damage occurs, enabling the material to restore its original properties. Their ability to mend themselves not only extends the lifespan of products but also reduces maintenance costs and waste, making them highly attractive across various industries. Self-healing mechanism is a key feature that allows these materials to respond effectively to damage.

Self-healing polymers restore properties, extend lifespan, reduce costs, and cut waste across industries.

In biomedical applications, self-healing polymers hold tremendous potential for creating more durable medical devices, implants, and tissue engineering scaffolds. Imagine a biodegradable stent or a wound dressing that can repair small cracks or tears, maintaining integrity during use. Such materials could markedly improve patient outcomes by reducing the need for replacements or repeated surgeries.

Additionally, self-healing polymers can lead to smarter drug delivery systems that respond to damage or environmental changes, enhancing treatment precision. The ability to repair themselves in biomedical contexts ensures these materials can withstand the body’s dynamic environment, offering long-term functionality and safety.

Beyond healthcare, self-healing polymers are revolutionizing industrial durability. Think about protective coatings on ships, bridges, or pipelines that can automatically repair minor damages caused by corrosion, weather, or mechanical stress. This self-maintenance reduces downtime and prevents costly failures, making infrastructure safer and more reliable.

In consumer electronics, self-healing screens and casings can recover from scratches or small impacts, prolonging the usefulness of devices and decreasing electronic waste. Such innovations not only improve product longevity but also promote sustainability by minimizing the need for replacements.

Furthermore, the science behind self-healing polymers continues to advance, with researchers developing new formulations that respond faster and more efficiently to damage. Some use microcapsules filled with healing agents, which rupture upon damage, releasing substances that fill cracks.

Others rely on reversible chemical bonds, which reform after breaking, restoring the material’s strength. These mechanisms are designed to work seamlessly, often triggered by heat, light, or mechanical stress, ensuring the material’s healing process is both quick and effective.

Recent developments in smart material technology are further enhancing the capabilities of self-healing polymers, making them more adaptable and efficient. In essence, self-healing polymers are transforming how we think about materials and their durability. They combine innovation with practicality, promising longer-lasting, more resilient products across many sectors.

Their ability to repair themselves like human skin isn’t just a fascinating scientific breakthrough—it’s a step toward smarter, more sustainable technology that adapts and heals itself in real time.

Frequently Asked Questions

Can Self-Healing Polymers Be Used in Medical Implants?

You might wonder if self-healing polymers can be used in medical implants. They hold promise, but you need to guarantee biocompatibility testing confirms they’re safe for your body.

Regulatory approval is essential before these materials can be widely adopted in healthcare. If they pass rigorous testing and regulations, self-healing polymers could revolutionize implants by reducing failures and improving longevity.

Ultimately, this could benefit your health and recovery process.

How Many Times Can These Polymers Repair Themselves?

Think of self-healing polymers as a resilient storyteller, capable of rewriting their own endings. You might wonder how many repair cycles they can handle—some can mend dozens of times, while others face durability concerns after repeated healing.

The number of repairs depends on the material’s formulation and the severity of damage. While they’re impressive, keep in mind that each repair might slightly diminish their overall strength over time.

Are Self-Healing Polymers Environmentally Friendly?

You wonder if self-healing polymers are environmentally friendly. These materials can reduce waste and extend product lifespans, but their environmental impact depends on their composition.

Biodegradable plastics are a promising development, helping minimize pollution. If self-healing polymers incorporate biodegradable components, they could substantially lessen environmental harm.

However, some may contain chemicals that aren’t eco-friendly, so it’s crucial to evaluate their overall biodegradability and potential impact on ecosystems before deeming them environmentally safe.

Do They Require External Stimuli to Activate Healing?

Stimuli spark self-healing, so yes, these polymers often need external stimuli to activate repair triggers. You might apply heat, light, or pressure to prompt the material to mend itself.

Without stimuli activation, the healing process stalls, leaving damage unaddressed. So, understanding the specific repair triggers helps you control when and how the polymer heals, making it a smart, responsive solution for durable, damage-resistant materials.

What Are the Limitations of Current Self-Healing Polymer Technology?

You should know that current self-healing polymer technology faces limitations in material durability and healing speed. These materials often degrade over time, reducing their effectiveness, and may take longer to heal than desired.

External stimuli can sometimes be needed for activation, which isn’t always practical. Such constraints hinder widespread application, especially in environments demanding rapid, long-lasting repairs, highlighting the need for ongoing research to improve these critical aspects.

Conclusion

Self-healing polymers are revolutionizing materials science, allowing surfaces to repair themselves and extend their lifespan. Imagine saving up to 50% on maintenance costs thanks to these smart materials—it’s like giving materials a second skin. With their ability to mend cracks and damages automatically, you can trust these polymers to make products more durable and sustainable. Embracing this technology means you’re not just improving materials; you’re shaping a future where repairs happen seamlessly and efficiently.