The chemistry of biocompatible inks is key to advancing 3D-printed organs. These inks contain materials like hydrogels or biodegradable polymers that support cell growth while maintaining safety. Chemists optimize formulations to guarantee compatibility with living tissues, control viscosity, and facilitate proper crosslinking. Developing these inks helps create organ scaffolds that mimic natural tissue and promote blood vessel growth. Exploring this chemistry can open the future of organ transplants and regenerative medicine.

Key Takeaways

- The chemistry of bio-inks involves balancing viscosity, curing properties, and biocompatibility to support cell viability during printing.

- Natural polymers like alginate, gelatin, and collagen are chemically processed to mimic extracellular matrices in bioprinting inks.

- Crosslinking agents are used chemically to enhance scaffold mechanical strength and control degradation rates.

- Incorporation of growth factors and signaling molecules into bio-inks relies on chemical stability and controlled release properties.

- Advances in biocompatible ink chemistry aim to improve organ functionality, vascularization, and integration post-printing.

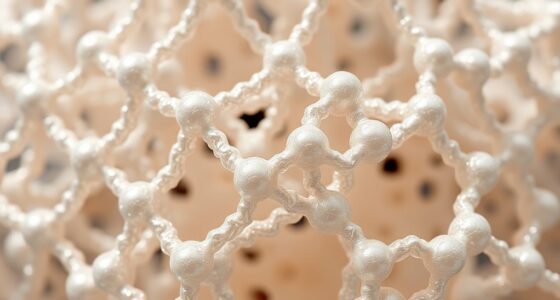

Have you ever wondered if 3-D printing could revolutionize organ transplantation? It’s an exciting possibility, but the journey to creating fully functional, biocompatible organs isn’t without hurdles. One of the biggest challenges lies in bioprinting, especially when it comes to developing reliable scaffold materials. These scaffolds serve as the foundation for growing tissues, guiding cell growth and ensuring the structure remains intact. However, finding the right materials that are both biocompatible and supportive of cell functions is a complex task.

Many scaffold materials tend to be either too rigid or too fragile, which can compromise the overall integrity of the printed organ. Additionally, ensuring these materials don’t trigger immune responses or toxicity remains a significant challenge. As you explore the chemistry behind biocompatible inks, you realize that researchers are constantly working to improve these materials, aiming for ones that mimic natural tissue properties while supporting cell adhesion, growth, and differentiation.

The chemistry of biocompatible inks involves a delicate balance of components that must be safe inside the human body. These inks often contain hydrogels, biodegradable polymers, or other bio-inks that can be precisely deposited layer by layer. Their formulation requires careful consideration of viscosity, curing time, and compatibility with living cells. Material chemistry plays a crucial role in optimizing these formulations for safe and effective use in bioprinting. Moreover, understanding the biocompatibility of these components helps minimize adverse reactions once implanted.

You’ll find that scientists are experimenting with natural polymers like alginate, gelatin, and collagen, which closely resemble the body’s extracellular matrix. The challenge is ensuring these materials can be processed without harming the cells they carry. This is where understanding the chemistry becomes critical. For instance, adjusting pH levels or crosslinking agents can influence the mechanical strength and degradation rate of the scaffold, directly impacting how well the tissue develops.

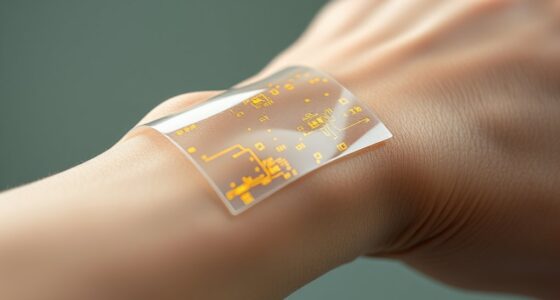

To address bioprinting challenges, researchers often incorporate growth factors and signaling molecules into the inks, promoting cell proliferation and maturation. The success of these biocompatible inks depends heavily on their ability to support vascularization — the formation of blood vessels — which is essential for organ viability.

The chemistry of these inks must facilitate not just cell survival but also proper tissue architecture. As you follow the advancements in bioprinting, it becomes clear that breakthroughs in scaffold materials and bio-inks are crucial for overcoming current limitations. Only by refining these chemical compositions can we hope to print organs that are fully functional, safe, and ready for transplantation, bringing us closer to a future where organ shortages might finally be a thing of the past.

Frequently Asked Questions

How Long Does It Take to Print a Fully Functional Organ?

Printing a fully functional organ varies greatly depending on its complexity and your printer’s speed. Simpler tissues might take hours, while complex organs like a heart could take several days or even weeks.

The printing speed directly affects the timeline, and more detailed structures require careful layering and precision.

You should plan for a lengthy process, especially if you aim for high accuracy and biocompatibility essential for transplant success.

Are Biocompatible Inks Biodegradable or Recyclable?

Did you know that some biocompatible inks are designed to be biodegradable within months? These inks undergo a natural biodegradation process, breaking down safely in the body or environment.

Recycling methods like ink reprocessing help minimize waste and reuse materials. While not all inks are recyclable, advancements focus on creating eco-friendly options that support sustainable practices, reducing long-term environmental impact and improving the safety of medical applications.

What Is the Success Rate of 3D Printed Organ Transplants?

You’re wondering about the success rate of 3D printed organ transplants, which is still evolving. Currently, clinical trials show promising results, but widespread success depends on gaining regulatory approval.

While some organs have been successfully transplanted in limited cases, many still face challenges like immune rejection. As technology advances and more trials are conducted, the success rate is expected to improve, bringing 3D printed organs closer to routine medical practice.

Can Printed Organs Integrate With the Body’s Immune System?

Imagine your body’s immune system as a vigilant gatekeeper, carefully inspecting new arrivals. When you get a printed organ, it can sometimes blend seamlessly, like a chameleon changing colors, thanks to advanced biocompatible inks.

These inks promote tissue integration and reduce immune response, helping the organ harmonize with your body. While promising, this technology still faces hurdles, but ongoing research endeavors to turn this harmony into a reliable symphony.

How Do Biocompatible Inks Mimic Natural Tissue Properties?

Biocompatible inks mimic natural tissue properties by optimizing cell adhesion and matrix stiffness.

You’ll find that these inks contain materials similar to the body’s extracellular matrix, promoting cells to attach and grow naturally.

They’re designed to match the tissue’s flexibility and strength, ensuring proper function.

This careful balance helps your printed organs integrate seamlessly, supporting healthy cell behavior and reducing immune rejection risks.

Conclusion

You now know that biocompatible inks are revolutionizing organ printing, turning science fiction into reality. Did you know that over 70% of the ink used in 3D printed organs is biodegradable? This means fewer rejections and healthier integration with your body. As technology advances, these innovative inks will make organ transplants more accessible and safer. So, stay excited—your future could involve lab-grown organs that are both functional and completely safe for you.