When recycling e-waste, chemistry plays a key role in recovering metals like gold, silver, and palladium. Techniques such as chemical leaching, solvent extraction, and electrochemical processes dissolve and separate these valuable materials from circuit boards securely and efficiently. Advanced methods also minimize environmental impact by reducing toxic waste and energy use. Want to see how these processes work in detail? Keep exploring to uncover the innovative chemistry behind electronics recycling.

Key Takeaways

- Chemical leaching using acids like aqua regia dissolves precious metals from e-waste at room temperature.

- Electrochemical methods, such as electrodeposition and e-LLE, extract and purify metals through redox reactions.

- Hydrometallurgical processes dissolve metals in aqueous solutions for selective recovery.

- Combining solvent extraction with chemical methods enhances efficiency and environmental friendliness in metal recovery.

- Specialized recycling techniques recover metals like gold, silver, palladium, and rare earth elements, reducing environmental impact.

The Journey Begins: From Collection to Material Sorting

The journey of e-waste recycling starts with effective collection methods that guarantee obsolete devices reach proper facilities. You can drop off your gadgets at designated recycling bins provided by local governments or businesses, ensuring they’re directed towards responsible processing. Take-back programs from manufacturers allow you to return devices directly, while community drives temporarily gather large quantities of e-waste. For corporate needs, on-demand pickup services handle bulky items efficiently. To prevent toxic mixing, specialized containers separate batteries and CRTs during collection. Once collected, secure transportation protocols come into play—certified recyclers track shipments with GPS, use fire-resistant packaging, and document the chain of custody. Proper collection ensures efficient recycling and environmental safety. Additionally, implementing tracking systems helps monitor the movement of e-waste, safeguarding against illegal dumping. This structured approach guarantees that e-waste is safely delivered for subsequent dismantling and processing, setting the foundation for responsible recycling.

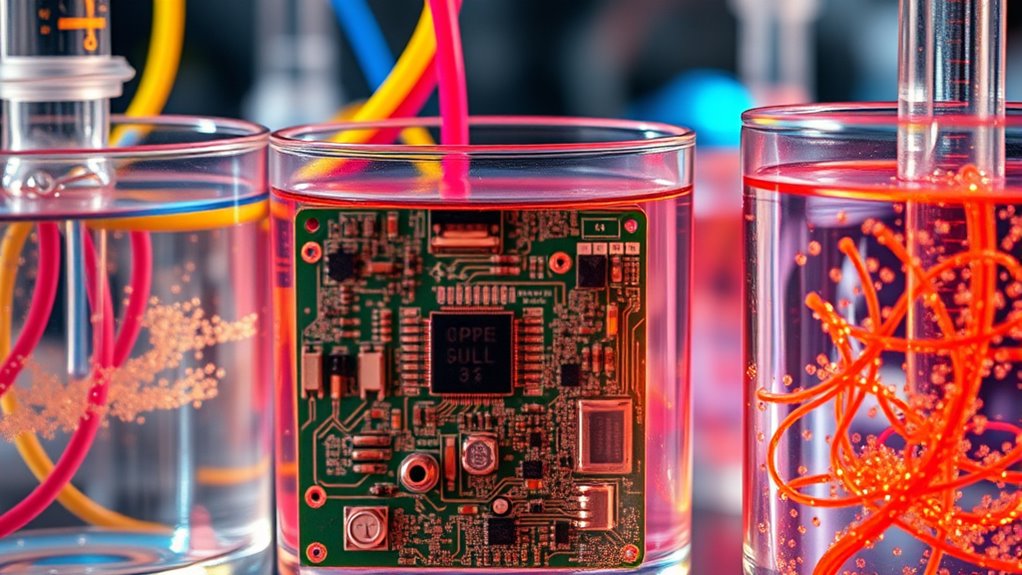

Chemical Methods in Metal Extraction

Chemical methods in metal extraction play a crucial role in reclaiming valuable materials from e-waste efficiently and sustainably. Electrochemical techniques, such as electrochemical liquid-liquid extraction (e-LLE), use redox reactions to selectively recover metals like gold, palladium, and platinum group metals. These processes stream dissolved metals over specialized electrodes to perform oxidation, leaching, and reduction, consuming less energy and fewer chemicals than traditional methods. This innovative electrochemical approach streamlines the recovery process and reduces environmental impact. Chemical leaching with acids like aqua regia dissolves metals at room temperature, with solutions processed using reducing agents to precipitate pure metals. Hydrometallurgical processes dissolve metals in aqueous solutions, enabling precise recovery through adjustments in solutions and reagents. Advances in automation and data-driven techniques combining solvent extraction with these methods further refines metal separation, making the entire process more efficient and environmentally friendly.

Isolating and Refining Precious Metals

Have you ever wondered how precious metals like gold, silver, and palladium are extracted and purified from electronic waste? The process begins with isolating these metals from other materials, often through pyrometallurgical or hydrometallurgical methods. These chemical processes are carefully controlled to maximize metal recovery while minimizing environmental impact. Gold, found in small but valuable amounts, is separated by smelting or chemical leaching, ensuring high purity. Silver and palladium are recovered similarly, taking advantage of their conductivity and resistance to corrosion. Since only about 20% of these metals are recycled globally, improving isolation techniques is essential. Refining involves removing impurities and achieving high purity, making recycled metals suitable for reuse in electronics. Effective isolation and refining reduce reliance on mining and help minimize environmental damage. These methods are indispensable for sustainable resource management and supporting the electronics industry’s future.

Electrochemical Techniques Enhancing Metal Recovery

Electrochemical techniques are revolutionizing metal recovery from electronic waste by offering more efficient and sustainable alternatives to traditional methods. You can use electrolytic media, both aqueous and non-aqueous, to recover metals through electrodeposition.

Electrochemical liquid-liquid extraction (e-LLE) employs reactions that reduce energy use and chemical waste, making the process greener. Specialized electrodes in extraction columns enable selective recovery of specific metals, improving purity.

Combining hydrometallurgical and electrochemical methods enhances the extraction of metals like copper and antimony. Techniques such as electrowinning and cyclic voltammetry optimize recovery efficiency, while rotating cylinder electrodes assess energy consumption.

These innovations lead to higher purity metals—like copper at 96 wt %—using less energy and fewer chemicals, making recycling safer and more sustainable. Self Watering Plant Pots are an example of innovative design that can also improve plant health with minimal maintenance, demonstrating how integrated systems can enhance efficiency across different fields.

Environmental and Economic Impacts of E-Waste Recycling

Recycling e-waste offers significant environmental and economic benefits, but it also poses serious challenges if not managed properly. Improper disposal or burning releases toxic chemicals like lead, mercury, and dioxins, contaminating soil and water and harming ecosystems. Toxic materials in electronics are hazardous substances that can leach into the environment if e-waste is not properly processed. Burning emits hazardous fumes, degrading air quality and threatening nearby communities’ health. E-waste accumulation makes land unsuitable for agriculture and contributes to climate change through greenhouse gases from decomposition. Economically, up to 70% of cobalt and valuable rare earth elements are lost without effective recycling, wasting finite resources. Advanced methods can recover more materials, reducing dependency on destructive mining. Recycling metals from e-waste uses less energy and emits fewer greenhouse gases, supporting sustainability. Proper management balances environmental protection and economic growth, maximizing the value and minimizing harm. Additionally, implementing advanced recycling techniques can significantly improve recovery efficiency and reduce environmental impact.

Frequently Asked Questions

What Types of Electronics Are Most Commonly Recycled for Metals?

You’re curious about which electronics are most commonly recycled for metals. Smartphones, laptops, and computers top the list because they contain valuable metals like gold, silver, copper, and palladium.

You’ll also find significant recycling in printers, hard drives, and networking equipment, which have substantial ferrous and non-ferrous metals. These devices are popular targets for recycling because they hold high concentrations of precious and base metals, making metal recovery worthwhile.

How Do Automated Sorting Machines Identify Different Materials?

You might imagine a recycling plant where a piece of electronic waste moves along a conveyor. Automated sorting machines identify materials using sensors like NIR and VIS spectrometry, which detect differences in color and reflectivity.

AI processes this data rapidly, enabling robotic arms to separate metals, plastics, and hazardous components efficiently. This technology guarantees high accuracy, speeds up recycling, and helps recover valuable materials like copper and precious metals.

Are There Health Risks Associated With Chemical Leaching Processes?

You’re asking if chemical leaching processes pose health risks. Yes, they do. Exposure to hazardous chemicals like mercury, lead, and cadmium during e-waste recycling can cause neurological damage, organ issues, and increased cancer risk.

Workers face dangers from inhaling, ingesting, or skin contact with these toxins. Without proper safety measures and regulations, these risks grow, especially in informal settings where protections are often lacking.

What Are the Challenges in Separating Mixed Metal Alloys?

Imagine you’re back in the age of alchemy—separating mixed metal alloys remains just as tricky today. You face challenges like similar physical and chemical properties, making it hard to distinguish and isolate individual metals.

Impurities, reaction control, and cost also complicate the process. Plus, scaling up lab techniques to industrial levels demands innovative technology, all while keeping environmental impact low and economic viability high.

How Is the Purity of Recovered Metals Verified Post-Refinement?

You verify the purity of recovered metals through a combination of chemical and instrumental techniques. You start with acid tests or electrochemical methods to confirm specific metals.

Then, you use tools like XRF spectroscopy or ICP-OES for precise, non-destructive analysis. These methods assure high recovery rates and accurate purity levels, with multiple tests and standards confirming your results.

This layered approach guarantees reliable verification of the metals’ purity after refining.

Conclusion

As you delve into e-waste recycling, remember that chemistry is your trusty sword in recovering precious metals efficiently and sustainably. With innovative techniques, you can transform discarded electronics into treasure, much like alchemists of old turning base metals into gold—minus the mystical mumbo jumbo, of course. By embracing these methods, you not only save resources but also prevent pollution, proving that even in the digital age, a little old-fashioned science still works wonders.