Metal–organic frameworks (MOFs) are porous, crystalline materials made from metal ions connected by organic linkers. They offer high surface areas and tunable pore sizes, making them excellent for gas storage, separation, and sensing. Beyond that, MOFs are used in catalysis, drug delivery, water purification, and energy storage. Their versatility and customizable structure mean they hold promise for many innovative applications. If you’re curious about how they can impact various fields, there’s plenty more to explore.

Key Takeaways

- MOFs are crystalline porous materials composed of metal ions/clusters linked by organic molecules, designed for high surface area and tunable pore structures.

- They excel in gas storage, separation, and catalysis due to their customizable pore sizes and chemical functionalities.

- MOFs are used in environmental remediation, pollutant degradation, drug delivery, sensing, and energy storage applications.

- Various synthesis methods, including solvothermal, mechanochemical, and microwave techniques, enable scalable production of stable MOFs.

- Emerging technologies incorporate MOFs into quantum computing, water purification, and multifunctional systems for sustainable solutions.

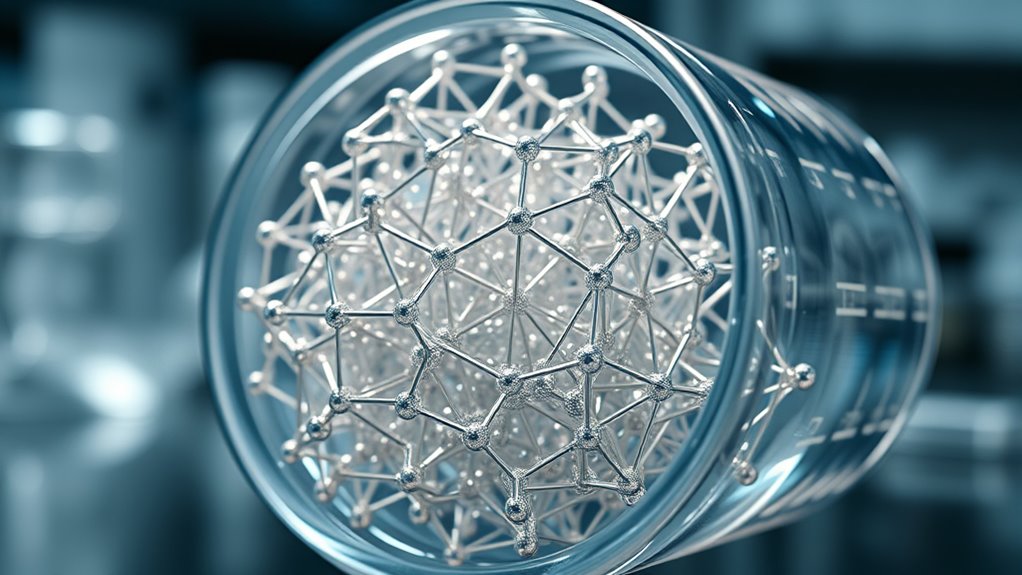

Understanding the Composition and Structure of MOFs

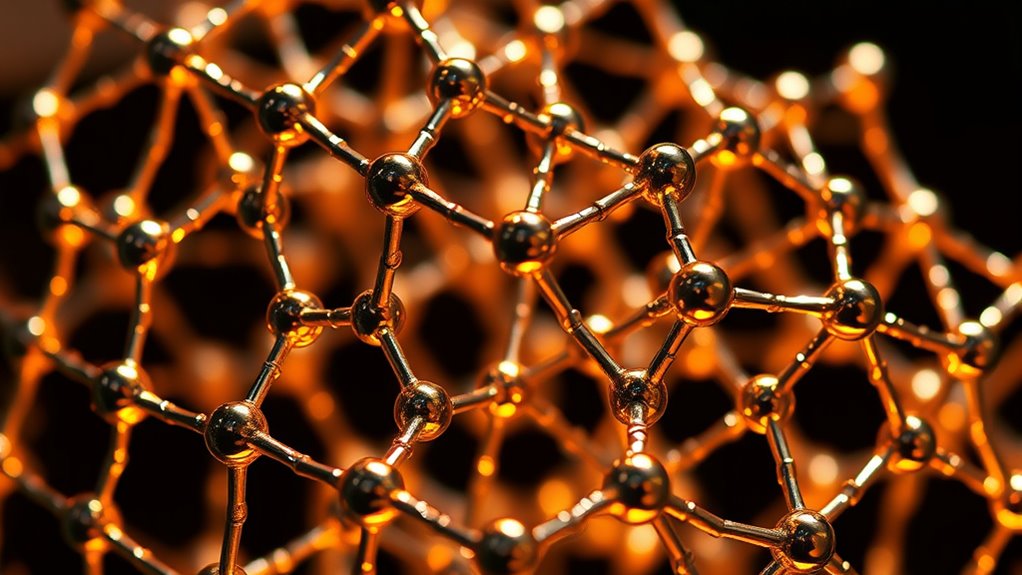

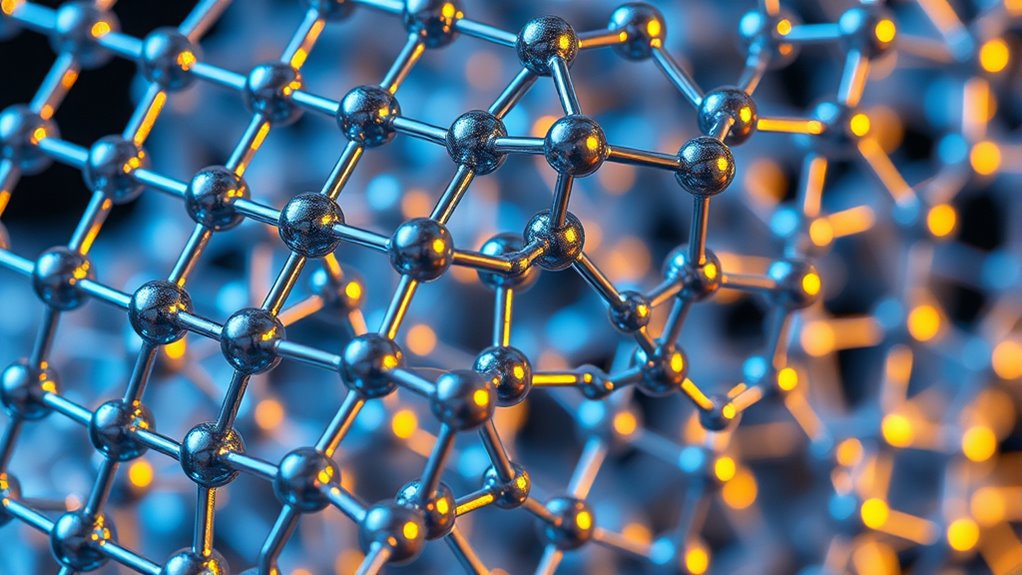

Metal-Organic Frameworks (MOFs) are composed of metal ions or clusters connected by organic molecules called linkers. These metal clusters, often called Secondary Building Units (SBUs), act as joint points in the framework. The organic linkers, typically multidentate ligands like 1,4-benzenedicarboxylic acid (BDC), bind to multiple metal sites, creating extended networks. Transition metals such as zinc, copper, iron, and aluminum are common choices, with metal salts like nitrates, acetates, or sulfates used in synthesis. This combination forms a highly porous, crystalline structure with customizable properties. The arrangement depends on the metal’s coordination geometry and the linker’s length, allowing for the creation of one-, two-, or three-dimensional frameworks. Additionally, the contrast ratio of MOFs can be tailored for specific applications, enhancing their usefulness in areas like gas storage and separation. This modular design makes MOFs highly tunable and versatile for various applications.

How MOFs Facilitate Gas Storage and Separation

How do MOFs achieve such impressive gas storage and separation capabilities? Their high porosity and surface area, often exceeding 5,000 m²/g, allow for exceptional gas adsorption. The tunability of pore sizes enables MOFs to selectively adsorb different molecules like CH₄, CO₂, and O₂ through physisorption, while monolithic designs optimize density for volumetric efficiency. Selectivity arises from host-guest interactions, where van der Waals forces and functionalized linkers enhance binding to specific gases. Pore chemistry customization targets polar or nonpolar molecules, enabling effective separation, such as CO₂ from N₂. The low-temperature operation and rapid kinetics facilitate quick adsorption and desorption cycles. Structural engineering, like linker modification and hierarchical porosity, further improves capacity and selectivity, making MOFs versatile for targeted gas storage and separation challenges. Advances in synthesis techniques also contribute to enhanced stability and performance of MOFs in practical applications. Additionally, ongoing research focuses on improving material stability, which is crucial for real-world deployment.

Diverse Applications of Metal–Organic Frameworks

The versatility of MOFs has led to their widespread application across various fields, driven by their customizable structures and high surface areas. In medicine, you can use MOFs for drug delivery, as their tunable pores enable controlled release and improve drug solubility. They also serve as biosensors, detecting biomolecules with high selectivity, and as imaging agents for diagnostics. Their high porosity and chemical tunability make MOFs ideal for encapsulating therapeutic agents and targeting specific tissues. MOFs exhibit antimicrobial properties by disrupting microbial growth. In catalysis, they act as heterogeneous catalysts for organic reactions and energy-related processes like oxygen reduction and hydrogen evolution. Their porous nature allows for selective catalysis and stability under harsh conditions. Additionally, MOFs are valuable in sensing, serving as luminescent sensors for gases and pollutants, and in energy storage, enhancing supercapacitors and batteries for sustainable energy solutions.

Methods for Synthesizing MOFs

Understanding the various methods to synthesize MOFs is key to tailoring their properties for specific applications. The most common approach is solvothermal or hydrothermal synthesis, where you dissolve metal salts and organic linkers in solvents, then heat the mixture under high temperature and pressure. Adjusting the solvent, temperature, and reaction time allows control over crystal size and nucleation, often resulting in high-quality single crystals. This method has been widely studied and optimized, leading to numerous commercial applications. Alternatively, mechanochemical synthesis uses grinding of solid reactants with minimal solvent, making it environmentally friendly and scalable, though it can cause inconsistent particle sizes.

Sonochemical methods employ ultrasound waves to create localized hot spots, speeding up formation and producing nanoscale MOFs.

Microwave-assisted synthesis offers rapid, uniform heating, reducing reaction times and improving crystal quality.

Each method helps you customize MOFs for specific uses.

Key Properties and Characteristics of MOFs

Metal-Organic Frameworks (MOFs) stand out for their exceptional porosity and large surface areas, making them highly effective for gas storage, separation, and catalysis. Their internal pore structures are highly tunable, allowing you to customize pore sizes based on your needs. This porosity remains stable even after removing guest molecules like solvents, enabling repeated use. Additionally, the diverse designs available and material options, including recycled products, enhance their adaptability for various applications. Structurally, MOFs are crystalline coordination polymers formed from metal ions or clusters linked with organic ligands, creating 1D, 2D, or 3D networks that can adapt under different conditions. Their chemical diversity, achieved through various functional groups and post-synthetic modifications, supports tailored applications.

Additionally, MOFs demonstrate good thermal stability and resistance to environmental factors, with particle size and morphology controllable to optimize performance in specific uses.

Challenges and Future Perspectives for MOF Development

Despite their promising properties, developing MOFs for practical applications faces significant hurdles, primarily related to stability and structural integrity. Large-pore MOFs often collapse during desolvation, and maintaining framework strength under operational conditions remains tough, especially for highly porous structures. Improving robustness without losing porosity or function is essential. Repeated adsorption/desorption cycles can degrade MOFs, limiting their use in gas storage. To combat this, researchers explore post-synthetic modifications and composite materials. Additionally, the synthesis processes can influence the overall stability and performance of MOFs, highlighting the importance of refining manufacturing techniques.

Advantages of MOFs Over Traditional Materials

The unique structural features of MOFs give them clear advantages over traditional materials like zeolites and activated carbons. Their high porosity and surface area enable greater gas storage and adsorption.

The crystalline structure provides stability and versatility, while the ability to tailor properties by adjusting metal ions and organic ligands allows for customization to specific applications.

MOFs also boast high thermal stability thanks to strong coordination bonds. Their multidimensional frameworks—one, two, or three-dimensional—offer a wide range of structural options.

These features result in superior gas selectivity, larger storage capacity, and effective molecular sieving. Additionally, tunable pore sizes enhance gas separation efficiency, and their design flexibility supports energy-efficient processes, making MOFs a significant improvement over traditional materials in gas storage and separation.

Emerging Trends and Innovations in MOF Research

How are recent innovations transforming MOF research into a powerhouse of multifunctional applications? Advances in photocatalysis and environmental remediation show how MOFs now rapidly degrade chemical warfare simulants and organic dyes while generating hydrogen under solar light. Additionally, emerging technologies are harnessing quantum computing to analyze and predict complex MOF structures, significantly accelerating discovery and optimization processes. Engineers are designing MOFs for pollutant detection and water purification, combining sensing and removal in one material. Machine learning accelerates discovery by predicting properties and guiding structure design, supported by large MOF databases for targeted applications like gas storage and catalysis. Commercial efforts focus on scalable, stable MOF-based gas systems for hydrogen and natural gas, with firms like Numat leading. Emerging research also explores MOFs for photocatalytic CO2 reduction, pushing toward sustainable carbon capture solutions. These innovations make MOFs versatile tools across energy, environment, and sensing fields.

Frequently Asked Questions

What Environmental Impacts Are Associated With MOF Production?

You should know that MOF production impacts the environment in several ways. Extracting metals and organic ligands harms ecosystems and consumes energy, increasing carbon emissions.

The process relies on toxic chemicals and high energy use, which can pollute water and air. Additionally, managing waste and end-of-life MOFs poses environmental risks if not properly handled.

Moving to greener methods and recycling can help reduce these negative effects.

How Do MOFS Behave Under Long-Term Operational Conditions?

You should know that under long-term conditions, MOFs can face challenges like chemical degradation, moisture sensitivity, and pore blockage, which can reduce their performance.

Some MOFs are thermally stable, but others may degrade over time, especially if exposed to impurities or environmental factors.

To guarantee their durability, selecting MOFs with proven stability and proper handling is essential, especially for applications like gas storage, drug delivery, or medical uses.

Can MOFS Be Integrated Into Existing Industrial Systems?

Imagine trying to fit a new gear into a well-oiled machine—that’s what integrating MOFs into existing systems feels like. You face challenges like scaling up production, controlling costs, and ensuring stability under industrial conditions.

While the potential is immense, you need to navigate environmental impacts and economic viability carefully.

With ongoing technological advances, like flow chemistry, you’re moving closer to seamlessly weaving MOFs into your industrial fabric.

What Are the Safety Considerations for Using MOFS?

When considering safety, you should be aware that MOFs can pose risks during synthesis and application. They might release nanoscale particles or chemicals into the environment or your body, depending on their size and stability.

Handling chemicals carefully, managing waste properly, and following safety guidelines are essential. Using computational tools helps predict hazards.

Developing greener synthesis methods and designing more stable MOFs also reduce potential health and environmental impacts.

Are MOFS Biodegradable or Environmentally Sustainable?

They say “what’s old is new,” but with MOFs, it’s clear they’re not naturally biodegradable or environmentally sustainable yet. You’ll find that these structures, made from metals and organic parts, pose challenges in recycling and disposal.

However, researchers are working on greener synthesis methods and sustainable designs. You can play a role by supporting innovations that make MOFs safer and more eco-friendly for future use and environmental health.

Conclusion

As you explore the world of MOFs, you’ll find they’re quietly transforming industries with their remarkable abilities. While challenges remain, ongoing innovations promise even brighter horizons. Embrace the potential of these versatile materials, as their delicate complexity hints at a future where efficiency and sustainability grow hand in hand. With each breakthrough, you’ll see how MOFs gently reshape our approach to energy, environment, and beyond—ushering in a new era of advanced, harmonious solutions.