Aerogels are the lightest solids on Earth, with densities much lower than water, making them ideal for innovative uses. They’re made from materials like silica or carbon, featuring a large surface area and high porosity. You’ll find them in insulation, electronics, and even space exploration. Advances in manufacturing let us create stronger, more flexible forms. To discover surprising ways aerogels are transforming industries, keep exploring how these incredible materials are evolving.

Key Takeaways

- Aerogels are among the lightest solids, with extremely low density due to their porous, networked structure.

- They possess exceptional insulating properties, making them ideal for energy-efficient building and equipment applications.

- Their high surface area and porosity enable use in filtration, catalysis, and chemical sensing.

- Advanced manufacturing allows aerogels to be flexible, conductive, or reinforced for innovative uses like wearable tech and space gear.

- Ongoing research explores aerogels in lightweight batteries, environmental cleanup, and next-generation thermal insulation.

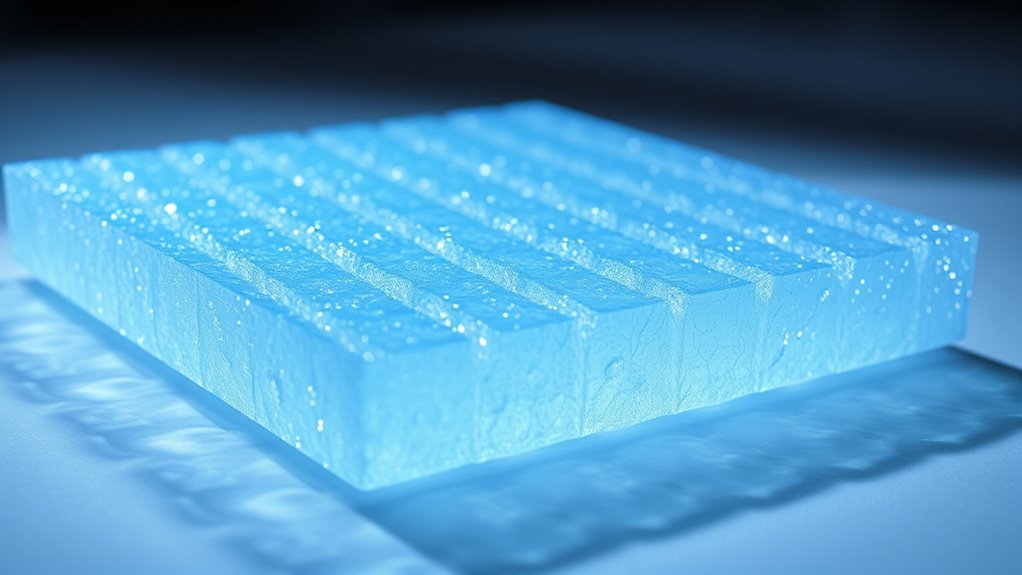

Aerogels are remarkable materials known for their extremely low density and exceptional insulating properties. These lightweight solids have fascinated scientists and engineers for decades, owing to their unique structure and versatile applications. To understand their origins, it helps to explore their historical development. The concept of aerogels dates back to the 1930s when scientists first experimented with supercritical drying methods to create ultra-light materials. Early efforts focused on silica-based gels, which were fragile and difficult to produce consistently. Over the years, advances in chemistry and manufacturing techniques allowed researchers to refine the process, making aerogels more durable and scalable for commercial use.

Aerogels, lightweight and insulating, originated in the 1930s with supercritical drying techniques for silica gels.

Today, they’re not just laboratory curiosities but practical materials used in insulation, electronics, and even space exploration. Manufacturing techniques have been crucial in expanding the range of properties and applications of aerogels, enabling their integration into various industries. Additionally, ongoing research into advanced processing methods continues to improve their performance and cost-effectiveness for broader adoption.

When it comes to manufacturing techniques, you’ll find that creating aerogels involves an intricate yet fascinating process. It starts with forming a gel—typically silica, but also other materials like carbon or metal oxides—by mixing precursor chemicals. This gel contains a large amount of liquid within a solid network. The key to transforming this into an aerogel is removing that liquid without collapsing the delicate structure. To do this, you’ll use supercritical drying, where the liquid is carefully replaced with a supercritical fluid, often carbon dioxide, which can be vented away without causing surface tension forces that would damage the gel.

This process results in a porous, low-density solid with a large internal surface area. Advances in manufacturing techniques have also enabled the production of aerogels with tailored properties—such as flexibility or enhanced strength—by modifying the chemical composition or incorporating reinforcements.

The development of manufacturing methods has also allowed for the creation of composite aerogels, which combine different materials to achieve specific goals. For instance, adding polymers can improve flexibility, while incorporating metal nanoparticles can impart electrical conductivity. These innovations expand the potential applications of aerogels far beyond traditional insulation.

As you consider their manufacturing, it’s clear that continuous improvements in techniques will lead to even more versatile and robust aerogels in the future. Whether used to insulate spacecraft or to develop lightweight batteries, the history and manufacturing of aerogels showcase how scientific curiosity and technological progress can turn a simple gel into one of the lightest, most remarkable solids on Earth.

Frequently Asked Questions

Are Aerogels Environmentally Sustainable and Biodegradable?

You might wonder if aerogels are environmentally sustainable and biodegradable. While they offer great benefits, they face biodegradability challenges because many are made from non-biodegradable materials like silica or synthetic polymers.

This can impact the environment over time. However, ongoing research aims to develop more eco-friendly aerogels with reduced environmental impact, making them a more sustainable choice in the future.

How Do Aerogels Perform in Extreme Temperature Conditions?

You might think aerogels can’t handle extreme temperatures, but they actually excel in thermal insulation and cryogenic performance. Their porous structure traps air, reducing heat transfer in scorching heat or freezing cold.

This makes them ideal for space exploration, cryogenics, and insulation in extreme environments. So, while they’re lightweight, aerogels perform remarkably well under harsh temperature conditions, proving their versatility in extreme conditions.

Can Aerogels Be Manufactured at a Commercial Scale Affordably?

You might wonder if aerogels can be produced affordably on a large scale. The good news is that ongoing innovations focus on cost reduction and manufacturing scalability, making mass production more feasible.

Industry leaders are developing new methods to lower costs and increase output, so you could soon see more affordable aerogels in various applications. This progress aims to bring these lightweight materials into everyday use without breaking the bank.

What Are the Safety Concerns When Handling Aerogels?

Oh, handling hazards with aerogels? It’s almost like working with fragile cotton candy—if that cotton candy could cause inhalation risks. You should wear gloves and masks because tiny particles can easily become airborne, posing inhalation risks.

While aerogels aren’t explosive, their fine dust can irritate your skin and lungs. So, stay cautious, handle with care, and avoid creating a cloud of dust during your experiments!

Do Aerogels Have Potential Uses in Energy Storage Technologies?

You might wonder if aerogels can boost energy storage technologies. Their high energy efficiency and excellent thermal insulation make them promising for this purpose.

By improving thermal regulation and reducing energy loss, aerogels can enhance batteries and supercapacitors. Their lightweight nature also offers advantages in device design.

Although still under research, integrating aerogels could revolutionize energy storage systems, making them more efficient and sustainable in the future.

Conclusion

Aerogels are the lightest solids on Earth, pushing the boundaries of what’s possible. They insulate better, absorb more, and innovate faster than traditional materials. You can use them for protection, for energy, or for exploration. Their potential is limitless, their applications extraordinary, their impact undeniable. Embrace the future with aerogels—because when it comes to pushing limits, lighter, stronger, smarter is the way to go.