Biotechnology combines microbes and chemistry to create sustainable materials from waste, like bio-based textiles, chemicals, and biomedical products. Engineers develop tailored microbes using tools like CRISPR to produce fibers, antimicrobial fabrics, and platform chemicals efficiently. Advanced bioreactors support large-scale, eco-friendly manufacturing. If you keep exploring, you’ll discover how this innovative approach transforms industries, reduces environmental impact, and opens new frontiers in sustainable material production.

Key Takeaways

- Microbes can genetically produce bio-based chemicals, fibers, and materials, integrating biotechnology with chemical manufacturing processes.

- Advanced bioreactors enable scalable microbial cultivation for sustainable production of textiles, biomedical materials, and functional fabrics.

- Genetic engineering tools like CRISPR facilitate precise microbial modifications to optimize material synthesis and properties.

- Microbial conversion of waste gases and algae-derived compounds offers eco-friendly routes to chemicals, fuels, and bioplastics.

- Biotechnology accelerates material innovation by designing microbes for targeted, cost-effective production of sustainable and functional materials.

Harnessing Microbial Resources for Sustainable Material Production

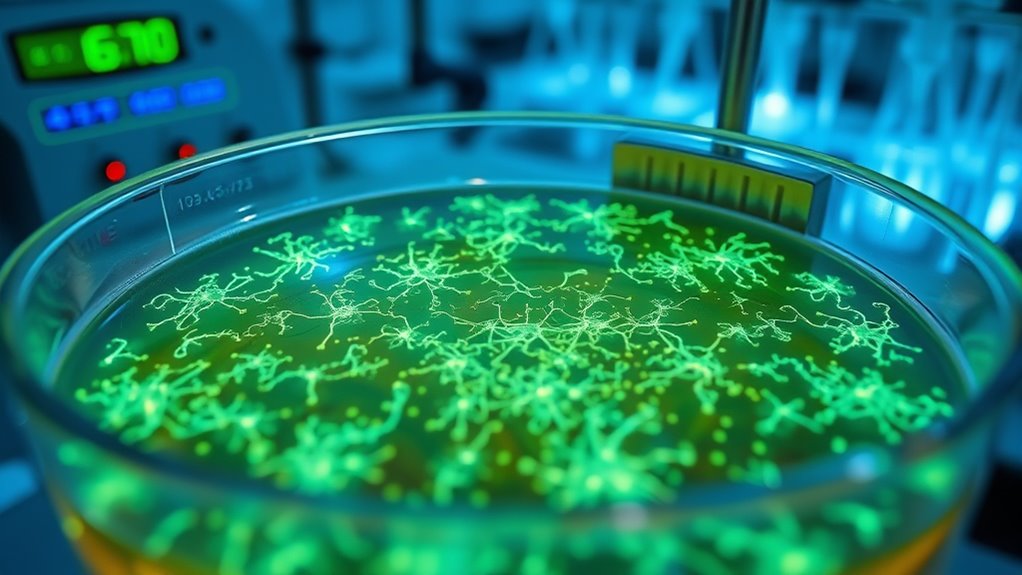

Microbial resources offer a promising avenue for creating sustainable materials that can replace traditional, fossil-based products. By harnessing microbes, you can produce bio-based chemicals, fuels, and materials from renewable resources. These microorganisms efficiently convert agricultural waste, plant materials, and other organic matter into valuable products, reducing reliance on non-renewable sources. Focusing on innovative microbial systems, researchers are developing new approaches to enhance efficiency and scalability in microbial production processes. Microbial engineering allows you to develop tailored strains that optimize production processes, making sustainable materials more viable and scalable. Using microbes not only helps lower greenhouse gas emissions but also promotes waste reduction through biodegradation. As you leverage advances in genomics and systems biology, you can improve microbial efficiency further. This approach supports a greener economy by transforming renewable resources into eco-friendly materials, paving the way for innovative, sustainable manufacturing alternatives.

Enhancing Microbial Capabilities Through Genetic Engineering

Advances in genetic engineering have substantially expanded the capabilities of microorganisms to produce sustainable materials. You can now target specific genes using tools like CRISPR-Cas9, enabling precise editing to enhance material synthesis. Techniques like PCR, restriction enzymes, BACs, and transfection introduce these modifications efficiently. This allows microbes to produce diverse materials such as textiles, biomedical products, and construction materials under ambient conditions. To illustrate, consider the following methods:

| Technique | Purpose | Application |

|---|---|---|

| CRISPR-Cas9 | Precise gene editing | Improve material production |

| PCR | Gene fragment modification | Genetic manipulation |

| BACs | Cloning large DNA fragments | Large-scale genetic engineering |

| Transfection | Introducing genetic material | Trait enhancement |

These tools make microbial engineering faster, more sustainable, and cost-effective. Advances in genetic engineering continue to drive innovation in microbial material production. Furthermore, ongoing developments in gene editing technologies are expanding the possibilities for customizing microbes for specific material outputs.

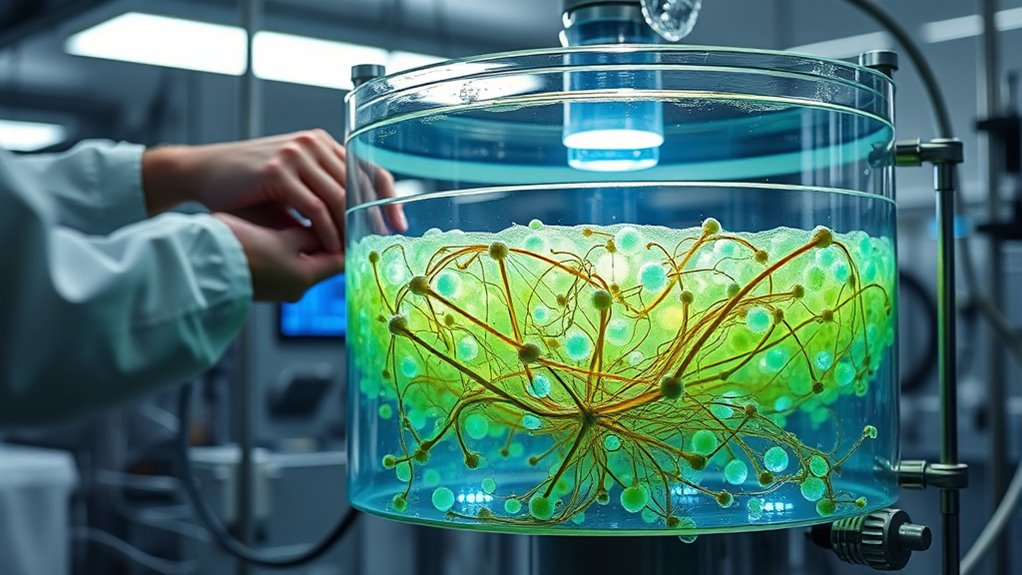

Innovative Bioreactor Designs for Microbial Growth and Material Synthesis

Innovative bioreactor designs are transforming how we cultivate microorganisms for material synthesis, offering greater efficiency, flexibility, and sustainability. Packed Bed Bioreactors (PBRs) use columns filled with solid supports like beads or fibers to promote biofilm growth, achieving high productivity with low costs and simple operation. Photo-bioreactors create controlled light environments for photosynthetic microbes, enabling biomass and biofuel production. Continuous bioreactors with dense microbial networks minimize water, energy, and nutrients, removing the need for sterilization between runs. Modular systems connect multiple small units in parallel, scaling production naturally and efficiently. Recent advances in materials, such as single-use bioreactors and nanotechnology, boost durability and flexibility. Integrated sensors and automation optimize conditions in real-time, enhancing yields, reducing contamination, and streamlining microbial growth for material synthesis. Bioreactor scalability continues to be a key focus, enabling the transition from laboratory experiments to industrial applications more smoothly. Additionally, innovations in sensor technology improve real-time monitoring and control, further increasing efficiency and consistency in microbial cultivation processes.

Microbial Fabrication of Textiles and Biomedical Materials

Bioreactor technologies that optimize microbial growth are now opening new possibilities in textile and biomedical material fabrication. You can develop antimicrobial textiles by using microbes to produce melt-spun fibers that eliminate microbes, making them ideal for medical and sportswear. Advancements in bioreactor design allow for large-scale, controlled cultivation of microbes, enhancing the efficiency and consistency of material production. Incorporating cerium oxide nanoparticles (CeO2NPs) into biotextiles creates fabrics that kill over 99% of bacteria like *E. coli* and *S. aureus*, even after washing. Bacterial cellulose (BC) combined with CeO2NPs produces durable, breathable fabrics with enhanced filtration, perfect for face masks. In biomedical applications, silk proteins from *Bombyx mori* serve as high-quality fibers, while recombinant spider silk offers improved properties. Advanced processing techniques enable the creation of scaffolds and implants, leveraging microbes for sustainable, biocompatible textiles in healthcare and beyond.

Microbial Conversion of Chemicals for Industrial Applications

Microbial conversion of chemicals transforms industrial waste gases into valuable products, offering a sustainable alternative to traditional manufacturing. By using bacteria like Clostridium autoethanogenum, you can turn waste gases such as carbon monoxide and carbon dioxide into essential chemicals. Microbial processes can potentially reduce reliance on fossil fuels and remove carbon from the atmosphere. This process reduces industrial emissions while creating marketable goods, aligning with circular economy principles. It’s an efficient way to convert by-products into valuable resources, boosting economic viability.

As research advances, scaling up microbial gas fermentation is becoming more feasible for industrial sectors, especially with new innovations in biotechnological methods that enhance efficiency. This approach not only minimizes waste but also leverages microbial metabolism to produce chemicals sustainably.

Microbial Role in Producing Platform Chemicals and Fuels

Building on microbial gas conversion, researchers are now harnessing various microbial platforms to produce a wide range of platform chemicals and fuels. Glycerol waste is converted into fuels and chemicals through microbial processes, while fungal systems produce organic acids and lipids via metabolic engineering. These efforts are supported by advances in synthetic biology and metabolic pathway optimization. Yeast platforms are optimized for alcohol and lipid biosynthesis with advanced genetics, enhancing efficiency and product specificity. Bacterial strains are engineered for high-yield biochemical synthesis like alcohols and specialty chemicals, leveraging recent developments in metabolic engineering. Microalgae, grown in photobioreactors, generate carotenoids and lipids for nutraceuticals and biofuels. Key microbial pathways include hydrolytic and acidogenic phases, thermophilic lignocellulose conversion, and anaerobic ethylene synthesis from CO₂. These innovations aim to meet global demands for bioethylene, bioalcohols, and microbial lipids, advancing sustainable chemical and fuel production.

Biotechnological Advances in Pharmaceuticals and Therapeutic Enzymes

Advances in biotechnology are transforming the development of pharmaceuticals through the creation of therapeutic enzymes, which are proteins engineered to catalyze specific reactions within the body. These enzymes treat illnesses by targeting biochemical pathways, with early examples like asparaginases now improved to enhance substrate affinity and reduce toxicity.

Enzyme engineering has boosted prodrug activation, making therapies more effective. Despite challenges like short lifespan in the body and immune responses, innovations such as molecular modifications and encapsulation extend enzyme stability and targeting. Frozen yogurt exemplifies how innovative biotechnological processes can lead to healthier food options, highlighting the potential for enzyme applications beyond medicine.

These therapies restore normal metabolism in conditions like cancer, fibrosis, and cardiovascular diseases, offering high specificity with fewer side effects than traditional drugs. Ongoing research explores novel enzyme-based treatments, including ACE2 therapies for COVID-19, pushing the boundaries of personalized medicine and biocatalysis.

Economic and Environmental Advantages of Microbial Materials

Harnessing microbes offers significant economic and environmental benefits that can transform industries and promote sustainable development. Microbial biotechnology drives economic growth by creating new businesses and jobs worldwide, especially in bio-based sectors that utilize renewable resources. It enables economic diversification, benefiting both developed and developing countries through accessible, sustainable solutions. Additionally, advancements in microbial research and development continue to expand the range of vetted microbial products available for various industries. Microbial products, like fertilizers, are cost-effective and locally producible, reducing reliance on expensive imports and chemical inputs, which boosts profitability for farmers and manufacturers. Environmentally, microbes support circular economy practices by recycling waste, capturing carbon dioxide, and reducing pollution from petrochemical inputs. They improve soil health, lower chemical use, and aid in ecological restoration.

Future Perspectives in Microbial Biotechnology for Material Manufacturing

The future of microbial biotechnology for material manufacturing hinges on cutting-edge tools like synthetic biology and metabolic engineering, which enable rapid development and optimization of microbial strains. You’ll see faster design-build-test cycles that tailor microbes to produce specific polymers and precursors efficiently.

Genome editing tools such as CRISPR allow precise modifications, boosting yields and process robustness. Adaptive laboratory evolution accelerates strain improvements, making microbes more resilient in industrial settings.

Combining biomass deconstruction with microbial fermentation enhances sustainability, converting lignocellulosic feedstocks into valuable materials. Emerging microbes like Rhodosporidium toruloides and extremophiles expand operational conditions, improving efficiency.

Advances in fermentation and downstream processing will lower costs and scale production, paving the way for bio-based plastics, biopolymers, and novel materials with broad applications in industries like automotive and packaging.

Predictive modeling and ethical considerations play crucial roles in optimizing microbial processes and ensuring responsible development in this rapidly evolving field.

Frequently Asked Questions

How Do Microbes Improve the Sustainability of Material Production Processes?

Microbes boost sustainability in material production by converting waste and renewable resources into valuable products, reducing reliance on fossil fuels and petrochemicals. They lower greenhouse gas emissions and energy use during manufacturing.

You can harness their ability to biodegrade plastics and repair materials, which cuts waste and extends product lifespan.

Using microbes also promotes circular economies by transforming waste into raw materials, making processes cleaner, more efficient, and environmentally friendly.

What Are the Main Challenges in Scaling Microbial Material Manufacturing?

Scaling microbial material manufacturing presents several challenges you need to address. You’ll encounter issues like ensuring consistent product quality across large batches, preventing contamination, and optimizing culture conditions.

Cost is also a big factor, as scaling up can be expensive and complex. Additionally, integrating advanced technology for process control, meeting regulatory standards, and maintaining microbial stability are vital.

Overcoming these hurdles is essential for successful, large-scale microbial production.

How Does Directed Evolution Accelerate Microbial Material Synthesis?

You might think improving microbes takes years, but directed evolution speeds this up dramatically. By screening thousands of mutants in microfluidic droplets, you selectively enhance strains with higher material production.

This rapid process finds rare, high-performing variants, boosting yields by up to 70%. You then use genetic insights to refine strains further.

This approach accelerates the entire cycle, making microbial material synthesis faster, more efficient, and scalable for industrial applications.

Can Microbial Systems Produce Custom-Designed Materials?

You can leverage microbial systems to produce custom-designed materials by engineering microbes to tailor their biosynthetic pathways. Through genetic modifications, you direct microbes to generate specific properties, like unique protein structures or material compositions.

Using advanced techniques like directed evolution, you can optimize strains for higher efficiency and desired traits, making microbial production a versatile and sustainable way to create materials precisely suited to your needs.

What Is the Environmental Impact of Microbial Biomanufacturing Compared to Traditional Methods?

Picture traditional manufacturing’s heavy emissions and waste, then contrast it with microbial biomanufacturing’s cleaner, waste-reducing process. You see microbes transforming waste into valuable materials, cutting fossil fuel reliance, and capturing carbon.

While traditional methods often pollute and consume energy, microbial processes use renewable resources and generate fewer toxins. Overall, microbial biomanufacturing offers a more sustainable, lower-impact alternative, helping you reduce environmental harm while producing valuable materials efficiently.

Conclusion

As you explore this frontier where biotechnology and chemistry intertwine, you’ll find microbes transforming industries like artists with a palette of possibilities. They’re your tiny, invisible architects building sustainable materials, fuels, and medicines—turning the tide toward greener, more innovative solutions. Embrace this microbial revolution, because like a seed that grows into a forest, these tiny workers hold the power to reshape our world, one molecule at a time.