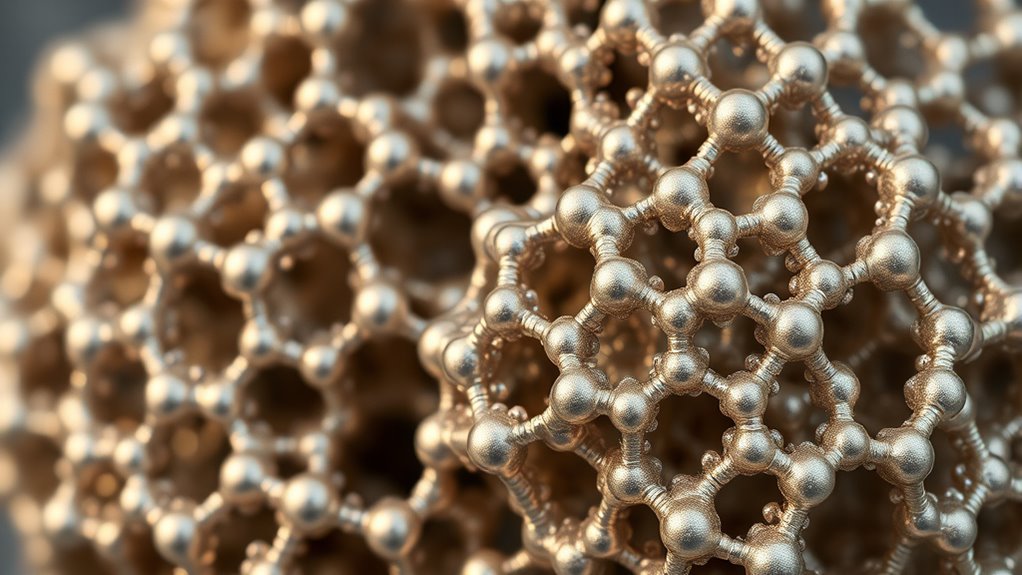

Metal-Organic Frameworks (MOFs) are porous, sponge-like crystals made from metal ions and organic linkers. They trap gases like carbon dioxide efficiently thanks to their high surface area and tailored pore sizes. MOFs are versatile and find uses in gas storage, separation, catalysis, and even drug delivery. Their customizable structure allows for innovative applications, making them essential for sustainable energy, environmental solutions, and more. Exploring further reveals how these versatile materials can impact your world.

Key Takeaways

- MOFs are porous, sponge-like crystalline materials capable of trapping gases like CO₂ due to their high surface area.

- Their structure consists of metal nodes and organic linkers, allowing customization for specific gas capture applications.

- MOFs are used in carbon capture, gas storage, catalysis, and environmental remediation.

- Advances in synthesis enable precise control over pore size and chemical functionality to enhance trapping efficiency.

- Their versatility supports sustainable solutions for pollution reduction and energy storage technologies.

Have you ever wondered how scientists create materials with incredibly high surface areas and tunable properties? The answer lies in the fascinating world of metal-organic frameworks, or MOFs. These structures are like tiny, sponge-like crystals that can trap gases, liquids, or even reactive molecules.

The process of MOF synthesis involves carefully combining metal ions or clusters with organic linkers under specific conditions, resulting in highly ordered porous networks. You can think of it as building a molecular lattice where each component plays a vital role in determining the framework’s structure and function. This meticulous assembly enables researchers to tailor MOFs for a variety of applications, whether it’s capturing greenhouse gases, storing fuels, or delivering drugs.

When it comes to applications of MOFs, the possibilities seem almost endless. Their high surface area, often exceeding 7,000 square meters per gram, makes them ideal for gas storage and separation. For example, they can selectively adsorb carbon dioxide from industrial emissions, helping to combat climate change.

Beyond environmental uses, MOFs are making waves in energy storage—some frameworks can hold hydrogen or methane efficiently, paving the way for cleaner fuel technologies. Their tunability allows scientists to modify pore sizes and chemical functionalities, optimizing them for specific tasks. Additionally, advances in MOF synthesis techniques continue to expand their capabilities and performance.

In catalysis, MOFs serve as platforms that improve reaction efficiencies, thanks to their accessible active sites and customizable environments. The biomedical field also benefits from MOFs’ properties; researchers explore their potential for drug delivery, where their porous nature allows for encapsulating therapeutic agents and releasing them in targeted areas. Understanding the metal-organic framework structure helps in designing more effective and stable materials for these applications.

The versatility of MOFs hinges on the ongoing advancements in MOF synthesis. By tweaking reaction conditions—such as temperature, solvents, and ratios—you can influence the size, shape, and stability of the frameworks. This precise control guarantees that each MOF can be customized for its intended purpose.

Furthermore, researchers continuously develop new organic linkers and metal nodes, expanding the library of MOFs with unique functionalities. As a result, these materials aren’t just theoretical constructs; they’re practical tools ready to address real-world challenges.

Whether it’s filtering pollutants, storing energy, or facilitating chemical reactions, MOFs stand out because of their adaptable, high-performance nature. As science progresses, you’ll see even more innovative applications emerge, making MOFs an essential part of the future technology landscape.

Frequently Asked Questions

Are MOFS Environmentally Sustainable and Eco-Friendly?

You might wonder if MOFs are eco-friendly. While they offer benefits like capturing carbon, concerns about biodegradability and environmental impact remain.

A thorough life cycle assessment shows that producing and disposing of MOFs can have environmental costs. However, ongoing research aims to develop more sustainable MOFs, making them a promising but still evolving technology for eco-conscious applications.

How Do MOFS Compare to Other Carbon Capture Technologies?

Pondering the performance of carbon capture technologies, you’ll find MOFs stand out with their superb specificity and capacity. Compared to traditional methods, MOFs often offer better efficiency and potential for scalability.

Though economic feasibility and scalability challenges remain, you might find that while conventional solutions are more established, MOFs promise innovative, customizable options—making them a compelling, cutting-edge contender in capturing carbon efficiently and effectively.

Can MOFS Be Used for Drug Delivery Applications?

You can definitely use MOFs for drug delivery, especially for drug encapsulation and targeted delivery. Their porous structure allows you to load drugs efficiently, while their tunable chemistry helps target specific cells or tissues. This means you can control where and when the drug releases, reducing side effects. Overall, MOFs offer a versatile platform that enhances precision in drug delivery, making treatments more effective and personalized.

What Are the Challenges in Large-Scale MOF Production?

Scaling struggles profoundly hinder MOF manufacturing. You face formidable scaling challenges, as producing MOFs on a large scale demands costly, complex processes.

Ensuring consistency, controlling quality, and maintaining cost-effectiveness complicate mass production. These manufacturing costs can balloon, making widespread application difficult.

Overcoming these obstacles requires innovative solutions to streamline synthesis, reduce expenses, and meet industrial demands, ultimately transforming MOFs from laboratory marvels into market-ready materials.

Are MOFS Resistant to Moisture and Chemical Degradation?

You might wonder if MOFs are resistant to moisture and chemical degradation. While their stability varies, many MOFs face challenges with moisture resistance and chemical stability, which can limit their long-term use.

Some MOFs are engineered for improved stability, but overall, their MOF stability can be compromised by moisture and harsh chemicals. Developing more robust MOFs remains a key focus to enhance their durability in real-world applications.

Conclusion

Think of metal-organic frameworks as tiny, sponge-like marvels, zealously soaking up carbon and other molecules like a thirsty traveler in a desert oasis. These crystals are your secret allies in the fight against pollution, holding onto harmful gases with the tenacity of a bear hugging its honey. As you explore their potential, remember—you’re revealing nature’s own puzzle pieces, turning these delicate structures into powerful tools for a cleaner, greener future.