MXenes are a new class of 2D materials discovered in 2011 that combine metal, carbon, and nitrogen layers. They’re produced by etching MAX phases, creating sheets with outstanding electrical conductivity, strength, and chemical activity. They’re used in energy storage, sensors, biomedical applications, and shielding. Their unique features also make them promising for future innovations. If you continue exploring, you’ll uncover how these versatile materials could transform various industries.

Key Takeaways

- MXenes are a family of 2D inorganic materials made from transition metal carbides, nitrides, or carbonitrides, discovered in 2011.

- They are produced by etching layered MAX phases, resulting in highly conductive, strong, and customizable materials.

- MXenes feature surface groups like oxygen, fluorine, and hydroxyl, enabling diverse chemical and electronic applications.

- They are used in energy storage, sensors, biomedical devices, and electromagnetic shielding due to their unique properties.

- Challenges include oxidation, stability, and scalable, safe synthesis methods, guiding ongoing research and development.

What Are MXenes and How Were They Discovered

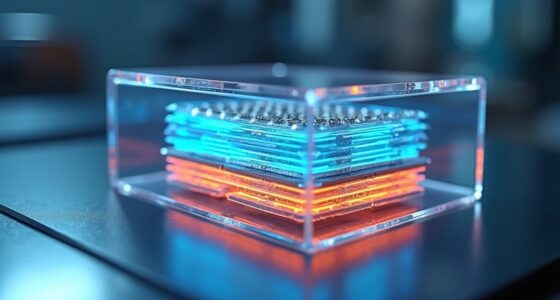

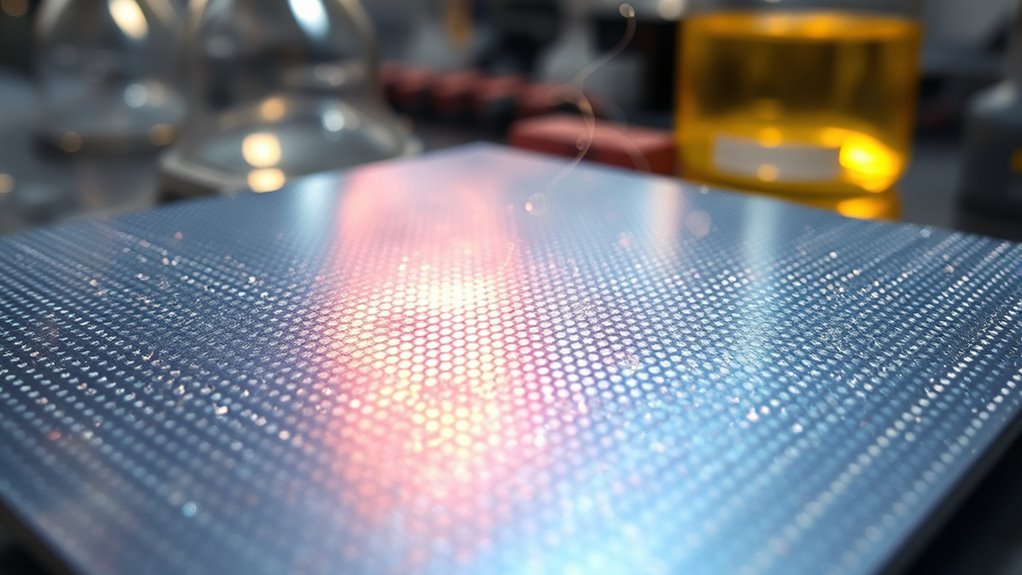

MXenes are a fascinating class of two-dimensional inorganic materials made up of transition metal carbides, nitrides, or carbonitrides. They’ve an accordion-like structure when first synthesized, often called multi-layer or few-layer forms.

Their general formula, M(_n)X(_n)T(_x), includes transition metals (M), carbon and/or nitrogen (X), and surface terminations (T) like oxygen, fluorine, or hydroxyl groups.

Discovered in 2011 by researchers at Drexel University, MXenes emerged as a new class of 2D materials, expanding beyond graphene. They’re derived from MAX phases through selective etching, which removes specific layers.

This breakthrough sparked worldwide interest due to their unique properties, including high electrical conductivity, mechanical strength, and biocompatibility, opening doors to numerous applications. Understanding potential regulatory challenges] is essential as the field advances.

How Are MXenes Made? Exploring Synthesis Techniques

To produce MXenes, researchers primarily rely on etching techniques that selectively remove certain layers from precursor materials. The most common approach is the top-down method, where acids like hydrofluoric acid (HF), LiF/HCl, or NH4HF2 dissolve the aluminum or other A layers from MAX phases. High refresh rates enhance performance in applications such as gaming and real-time processing. This process creates surface terminations such as –OH, –F, and –O, which influence properties. Aqueous etching systems improve safety and efficiency by operating at low temperatures. Molten salts offer controlled etching with fewer hazards. Alternatively, bottom-up synthesis assembles MXenes from molecular precursors, allowing precise control over size and surface functionalities. Some hybrid methods combine mechanical delamination with chemical techniques, reducing environmental impact and enhancing yield. Scalable production enables the manufacturing of MXenes in larger quantities, making them more accessible for commercial applications. These strategies enable scalable and tailored production of MXenes for various applications.

Unique Features and Properties of MXenes

Thanks to their exceptional electrical conductivity, MXenes are highly attractive for electronic applications, enabling fast charge transfer and efficient signal processing. Their robust mechanical properties ensure durability and versatility in various environments. Their unique layered microstructure provides pathways for ion transport, which is beneficial for energy storage devices. Additionally, the accessibility of synthesis methods allows for diverse customization options that meet various application requirements. With a large surface area, MXenes interact strongly with other materials, enhancing their functionality. Their layered microstructure, similar to graphene, provides unique optical and electronic properties, which can be tuned through different synthesis methods. Surface functional groups like O, F, and OH increase chemical activity and enable customization for specific uses. MXenes respond to external stimuli—conductivity changes under pressure and temperature—making them ideal for sensors. Their high biocompatibility opens doors for biomedical applications. Furthermore, ongoing research into their environmental stability is expanding their potential applications across various fields. Altogether, these features make MXenes a versatile and promising class of 2D materials.

Practical Uses of MXenes in Various Fields

The versatile properties of MXenes make them highly suitable for real-world applications across diverse fields. In wearable sensors, their electrical and biological traits allow precise monitoring of physiological signals, detecting pressure, strain, and biomolecules. Their hydrophilic surfaces ensure better contact with tissues and fluids, enabling real-time health and motion tracking.

For energy storage, MXenes’ high conductivity and surface area boost battery and supercapacitor efficiency, offering fast charging and high capacity. They serve as electrodes in lithium-ion and sodium-ion batteries, with surface functionalization tuning their electrochemical performance.

In biomedical fields, MXenes assist in bioimaging, antibacterial treatments, and drug delivery, thanks to their optical and biocompatible qualities. Additionally, they provide effective electromagnetic interference shielding and form the basis for advanced optoelectronic sensors, supporting various technological innovations.

Future Directions and Challenges for MXenes

Despite their promising potential, MXenes face significant hurdles that could limit their widespread adoption. One major issue is aggregation, which hampers processing and application.

Their susceptibility to oxidation, especially in aqueous environments or at high temperatures, also threatens stability. Additionally, the high costs and safety concerns linked to toxic etching agents like HF pose challenges for large-scale production.

The complex synthesis process, often relying on MAX phases, needs simplification for scalability. To overcome these hurdles, you’ll need to focus on developing safer, cost-effective synthesis methods, improving stabilization techniques, and enhancing delamination processes.

Scaling up production, reducing toxicity, and ensuring long-term stability are critical steps to access MXenes’ full potential across energy, catalysis, and electronic applications.

Frequently Asked Questions

How Do MXENES Compare to Other 2D Materials Like Graphene?

You might wonder how MXenes compare to other 2D materials like graphene. MXenes offer higher electrical conductivity, often surpassing graphene, and don’t need reduction steps to become conductive.

Their surface chemistry is tunable, enhancing sensitivity for sensors. Plus, MXenes disperse easily in water and excel in EMI shielding, energy storage, and water purification.

However, they require careful handling to prevent oxidation, unlike the more chemically stable graphene.

What Safety Considerations Are Involved in MXENE Production?

They say “prevention is better than cure,” and in MXene production, safety measures are vital. You must handle dust carefully with proper ventilation and PPE to avoid inhalation and explosions.

When working with toxic acids like hydrofluoric acid, follow strict protocols, use containment, and have emergency plans.

Scale-up demands automation and monitoring to prevent runaway reactions, ensuring both worker safety and environmental protection.

Can MXENES Be Integrated With Existing Electronic Devices?

You can definitely integrate MXenes with existing electronic devices. They offer high electrical conductivity and can be printed onto flexible substrates, making them compatible with current manufacturing methods.

Their strong adhesion and low contact resistance improve device performance. Plus, their flexibility allows seamless integration into wearable tech and flexible electronics.

While challenges like stability and oxidation exist, ongoing research is making MXenes more reliable for commercial electronic applications.

How Long Do MXENES Remain Stable in Different Environments?

You wonder how long MXenes stay stable in various environments.

In water saturated with oxygen, they last well at neutral pH but degrade faster in acidic conditions or with excess chlorine.

Under UV light, they remain stable, making them suitable for outdoor use.

At temperatures below 200°C, they hold their structure, but above that, they transform or oxidize—so your application’s environment determines their longevity.

Are There Any Environmental Impacts Associated With MXENE Disposal?

You should know that disposing of MXenes raises environmental concerns because they can persist and bioaccumulate, potentially harming ecosystems. You need proper waste management practices to prevent environmental contamination and guarantee controlled degradation.

Recycling and reuse strategies can help reduce waste, while adopting green chemistry methods minimizes environmental impacts during disposal. Being aware of toxicity and working collaboratively can further mitigate risks associated with MXene disposal.

Conclusion

Imagine a future where MXenes weave seamlessly into your daily life, transforming everything from energy storage to electronics. These ultrathin, shimmering sheets hold the promise of revolutionizing technology with their incredible strength and conductivity. As you explore their potential, picture a world powered by these versatile 2D materials, revealing innovations once thought impossible. With ongoing research and breakthroughs, MXenes are poised to reshape your world—bright, dynamic, and full of endless possibilities.