Shape-memory alloys are special metals that can “remember” their original shape and return to it after deformation. When you bend or shape them at lower temperatures, heating them causes a phase change that restores their initial form. These alloys are useful in medical devices like stents and orthodontic wires, as well as in aerospace structures for better aerodynamics. To understand how their unique transformation works and explore their full potential, keep exploring further.

Key Takeaways

- Shape-memory alloys can return to their original shape after deformation when exposed to heat or other stimuli.

- Their shape recovery is enabled by a solid-state phase transformation between martensite and austenite phases.

- SMAs are widely used in medical devices like stents and orthodontic wires due to their biocompatibility and responsive properties.

- In aerospace, they enable adaptive structures, improving aerodynamics, fuel efficiency, and durability of aircraft components.

- Their unique ability to “remember” shapes makes SMAs valuable for innovative, lightweight, and self-healing design solutions across industries.

Have you ever wondered how certain metals can “remember” their original shape after being deformed? It’s fascinating, but the secret lies in their unique ability called shape memory. These alloys, known as shape-memory alloys (SMAs), have the extraordinary capacity to undergo deformation and then return to their initial form when exposed to specific stimuli, usually heat.

This remarkable property is rooted in a solid-state phase transformation between martensite and austenite phases within the metal’s crystal structure. When you bend or twist an SMA at a lower temperature, it deforms into a new shape, but once you heat it past a certain point, it snaps back to its original form. This behavior isn’t just a scientific curiosity; it’s a game-changer across various industries, especially in biomedical applications and aerospace innovations.

In the world of medicine, SMAs are increasingly essential because of their biocompatibility and unique behavior. Imagine stents that can be inserted into blood vessels in a compact form and then expand to open up blocked arteries once heated to body temperature. Or consider orthodontic wires that adapt to the shape of your teeth, reducing discomfort and improving efficiency.

These biomedical applications leverage the ability of shape-memory alloys to respond predictably to body heat, making procedures less invasive and more effective. Their capacity to perform complex movements without sophisticated machinery simplifies device design, enhances patient comfort, and improves outcomes. Moreover, their versatility allows for innovative design solutions that were previously impossible with traditional materials. As research advances, you’ll see even more innovative medical devices that use SMAs to revolutionize patient care.

Shape-memory alloys enable minimally invasive medical devices that adapt seamlessly to body heat, improving patient comfort and treatment outcomes.

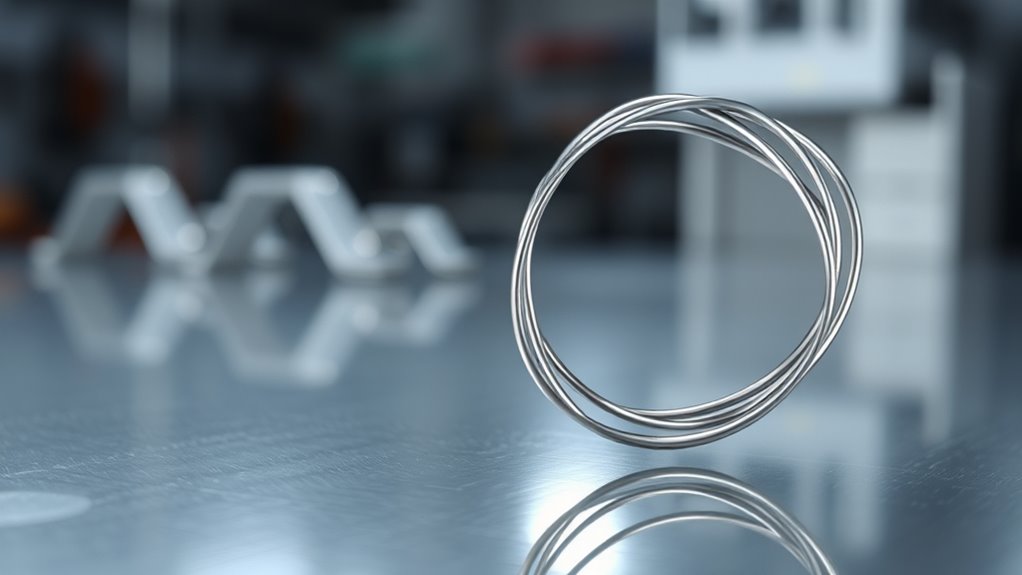

Aerospace innovations also benefit immensely from these metals. Engineers use SMAs in aircraft components, such as adaptive wing structures that can change shape mid-flight for better aerodynamics and fuel efficiency. Imagine airplane parts that automatically adjust to optimize performance without needing complex mechanical systems.

SMAs contribute to lightweight, reliable, and self-healing structures, reducing maintenance costs and enhancing safety. Their ability to withstand extreme conditions while reliably returning to a predetermined shape makes them ideal for aerospace applications, where precision and durability are indispensable. As aerospace technology pushes the boundaries of speed and efficiency, shape-memory alloys serve as fundamental materials that enable more flexible, resilient, and innovative designs.

In essence, shape-memory alloys are more than just metals that bounce back—they’re technological marvels shaping the future of medicine, aviation, and beyond. Their unique transformation capabilities open up endless possibilities, making complex tasks simpler and more efficient.

Whether helping save lives or pushing the boundaries of flight, SMAs prove that materials can be both smart and powerful. As you explore their potential, you’ll see that these alloys are truly the metals that remember and return, transforming industries and everyday life.

Frequently Asked Questions

How Long Do Shape-Memory Alloys Typically Last Before Degrading?

You might wonder how long shape-memory alloys last before degrading. In general, their longevity depends on factors like usage, environmental conditions, and material quality.

Longevity studies show they can last from thousands to millions of cycles, but degradation mechanisms—such as fatigue, corrosion, or phase changes—can reduce their lifespan over time.

Proper maintenance and selecting high-quality alloys help maximize their durability and performance.

Can Shape-Memory Alloys Be Recycled or Reused Effectively?

You might wonder if shape-memory alloys can be recycled or reused effectively. Recycling challenges often arise because these metals contain alloying elements that complicate traditional processes.

However, reuse methods like remelting or mechanical recycling can help extend their lifespan. While recycling is possible, it requires careful handling to maintain their unique properties, making reuse strategies essential for maximizing their durability and minimizing waste.

Are There Any Safety Concerns With Using Shape-Memory Alloys?

You might wonder if using shape-memory alloys is safe. While they offer great benefits, you should consider alloy toxicity, especially if they’re used in medical devices.

Potential thermal hazards from their temperature changes are also important to keep in mind. Proper handling and material selection can minimize risks.

Always guarantee you’re aware of the specific alloy’s safety data to prevent allergic reactions or burns, making your application both effective and safe.

What Are the Most Common Applications Beyond Medical and Aerospace?

Beyond medical and aerospace uses, you find shape-memory alloys in robotics applications where their flexibility and responsiveness enhance automation. They also play a role in architectural innovations, allowing structures to adapt or self-repair by changing shape when needed. These alloys offer unique advantages like lightweight durability and precise actuation, making them ideal for creative engineering solutions. Their versatility continues to expand across various fields, improving functionality and design.

How Do Environmental Factors Affect the Performance of Shape-Memory Alloys?

You should know that environmental factors like temperature sensitivity can substantially impact shape-memory alloys’ performance, causing them to lose their shape-memory effect if temperatures go beyond their range.

Corrosion resistance also matters; exposure to moisture or chemicals can weaken the material over time.

To maintain their reliability in various environments, it’s essential to contemplate these factors and select alloys designed to withstand specific conditions.

Conclusion

Imagine a metal that always remembers its original shape, no matter how much you bend or stretch it. Shape-memory alloys are like the loyal friends who never forget who they are, returning to their true form with ease. As you explore their fascinating properties, you’ll see how they transform industries and open new possibilities. These metals are not just materials; they’re a proof to nature’s incredible ability to surprise and inspire us at every turn.