Stretchable electronics for wearable tech rely on advanced polymers like PDMS, polyurethane, and silicone-based materials that offer flexibility, durability, and biocompatibility, ensuring comfort and long-term skin contact. Conductive nanomaterials such as silver nanowires and graphene enhance electrode performance, while innovative fabrication methods like multilayer printing and fiber technologies improve device integration and reliability. Organic polymers enable efficient biological signal conversion, boosting device sensitivity. To learn how these materials revolutionize wearable devices, keep exploring their latest developments.

Key Takeaways

- Elastomeric polymers like PDMS and polyurethane provide flexible, skin-compatible substrates for stretchable wearable electronics.

- Conductive nanomaterials such as silver nanowires and graphene enable durable, high-performance stretchable electrodes.

- Advanced fabrication techniques like inkjet printing facilitate scalable, multilayer, and customizable wearable device manufacturing.

- Organic polymers like OMIECs enable efficient biological signal conversion for health monitoring applications.

- Innovations include stretchable displays, bioresorbable electronics, and integrated sensors enhancing comfort, durability, and functionality.

Material Choices for Flexible and Stretchable Substrates

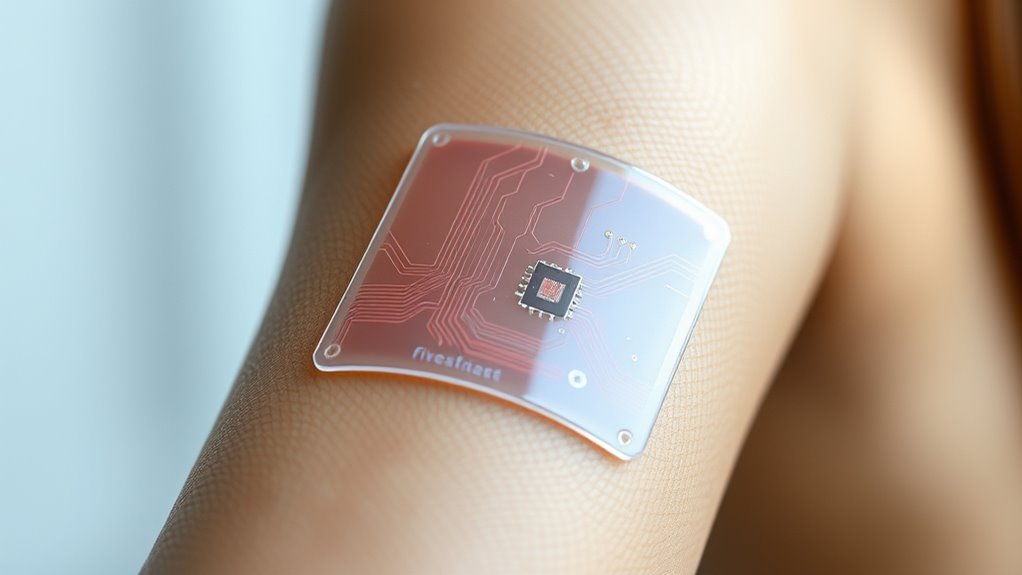

Choosing the right materials is vital for developing effective flexible and stretchable substrates in electronics. Elastomeric polymers like polydimethylsiloxane (PDMS) are popular because of their excellent elasticity and biocompatibility, making them ideal for wearable devices. High refresh rates enhance the responsiveness of flexible displays integrated into wearable tech, ensuring smooth visual performance. Polyurethane (PU) offers good mechanical stretchability and flexibility, guaranteeing comfort during daily wear. These elastomers provide a soft, skin-like feel that minimizes tissue irritation, essential for long-term contact with the body. Their inherent stretchability allows devices to maintain consistent electrical performance under repeated deformation. When combined with conductive elements, elastomers form the foundation of stretchable circuits. Silicone-based materials, especially silicones, enhance conformal contact with skin and support the integration of stretchable transistors and sensors. Additionally, advances in material engineering enable the development of new polymers with tailored properties for specific wearable applications.

Conductive Nanomaterials and Their Role in Stretchable Electrodes

Have you ever wondered how stretchable electronics maintain high conductivity while bending and stretching? Conductive nanomaterials like silver nanowires (AgNWs), graphene, and conductive polymers play a key role. AgNWs excel with their excellent conductivity, bendability, and stability, forming infiltration networks that enhance structural integrity.

Graphene and carbon-based materials like carbon black add mechanical strength and flexibility. Conductive polymers are versatile and adaptable for wearable devices. These nanomaterials create highly conductive, flexible, and breathable nano-networks through assembly techniques like inkjet printing and spray coating. Their nano-assembly techniques enable precise control over the nanostructure, optimizing performance.

They support the development of stretchable electrodes that combine durability with elasticity. By integrating nanomaterials into nanocomposites, you get improved performance, ensuring your wearable tech remains reliable under continuous movement and deformation. Additionally, understanding the various types of headphone jacks can help in designing more compatible and versatile wearable devices.

Furthermore, leveraging security measures in payment processing can ensure safe transactions for wearable tech consumers, enhancing trust and adoption.

Innovations in Multilayer Integrated Circuit Fabrication

Advancements in multilayer integrated circuit fabrication are transforming how electronic devices are built, offering greater complexity and performance in smaller footprints. Thick film processing remains essential, improving efficiency in printed circuit production. AI-driven security technologies are increasingly being integrated into manufacturing processes to enhance quality control and detect defects early in production. Additive manufacturing, like inkjet printing, enables rapid prototyping of complex multilayer circuits. Hybrid bonding technology facilitates seamless interconnects between stacked chiplets, supporting 3D IC designs. Multichip modules combine multiple functional layers, reducing size and boosting performance. Emerging 3D IC technology enhances performance while lowering power consumption. High-performance interconnects, such as through-silicon vias (TSVs) and hybrid bonding, improve data transfer and integration density. Innovations in design software, AI-driven manufacturing, and modular approaches further streamline fabrication, making multilayer circuits more versatile and efficient—key for advancing stretchable electronics and wearable tech. Additionally, the integration of remote collaboration tools in design and manufacturing processes accelerates innovation cycles and broadens access to expertise worldwide.

3D Fiber Technologies for Durable Medical Wearables

Innovative fiber technologies are transforming the development of durable medical wearables by emphasizing comfort, flexibility, and long-term reliability. You’ll find that material choices like biocompatible and breathable fibers are essential for continuous wear, guaranteeing skin-friendliness and minimal irritation.

Fiber-based sensors and smart fibers now deliver mechanical compliance and breathability, making wearables more comfortable during extended use. Conductive fibers enhance signal transmission and data collection, improving overall device performance. Natural materials and craftsmanship principles from Waldorf toys serve as inspiration for designing sustainable and eco-friendly fibers that reduce environmental impact while maintaining durability.

Modular design approaches allow for customization and easier manufacturing, while advanced platform development maintains consistent contact with skin. Combining high-performance fibers with efficient manufacturing techniques results in durable, flexible devices that meet medical standards.

Additionally, understanding SEER ratings can help in selecting materials and designs that optimize performance and durability over time. These innovations ensure your wearables aren’t only reliable but also comfortable enough for everyday, long-term health monitoring.

Organic Polymers and Their Biological Signal Conversion Capabilities

Organic polymers with biological signal conversion capabilities are transforming how wearable devices interface with the body. These materials, known as OMIECs, transport both ions and electrons, enabling efficient conversion of biological ion signals into electronic signals. This process is essential for devices like sweat-sampling smartwatches, which monitor health metrics in real time.

Unlike traditional materials that focus on ion uptake at the expense of electronic performance, OMIECs strike a balance, improving device functionality. They can mimic neurons by learning and retaining signals, supporting seamless integration with biological systems. This neuron-like behavior opens new possibilities for bioelectronics and body-machine interfaces, enhancing communication between natural and artificial components.

Organic polymers now enable more intuitive, responsive, and biocompatible wearable healthcare solutions.

Performance Breakthroughs in Size, Speed, and Sensitivity

Recent breakthroughs in stretchable electronics have dramatically enhanced size, speed, and sensitivity, enabling more capable wearable devices. Advances in transistor density, like Stanford’s stretchable arrays with 2,500 transistors per cm², let you build smaller, more powerful gadgets that are lightweight and comfortable.

Stretchable electronics boost device size, speed, and sensitivity for smarter, more comfortable wearables.

Improved display technologies, such as LG’s stretchable screens that expand 50% without damage, ensure durability and clarity during movement. Strain-resistant materials and innovative structures, like serpentine patterns, maintain electrical performance under stress, supporting complex motions.

Faster signal transmission results from high-mobility materials and optimized circuit layouts, allowing real-time data processing. Enhanced sensors, with increased surface areas and high sensitivity, capture precise bio-signals even during deformation.

These innovations collectively push wearable tech toward greater functionality, durability, and user comfort.

Medical Applications of Stretchable Electronic Devices

Stretchable electronic devices are transforming medical care by offering flexible, skin-like sensors that can monitor essential signs continuously and comfortably. You can wear these devices to track vital signs like heart rate, blood pressure, and oxygen levels non-invasively, reducing discomfort and infection risks.

Their advanced sensors detect subtle physiological changes, aiding in early diagnosis and personalized treatment. These wearables can provide real-time feedback, enabling autonomous management of health conditions.

Their design mimics skin, ensuring comfort and biocompatibility—key for long-term use. Additionally, their durability and moisture resistance allow for washing and everyday wear without losing functionality.

As a result, these innovations improve patient safety, enhance diagnostic accuracy, and support proactive healthcare, paving the way for more effective, personalized medical solutions.

Overcoming Challenges: Power, Manufacturing, and Biocompatibility

Overcoming the challenges in power, manufacturing, and biocompatibility is essential for advancing stretchable electronics from laboratory prototypes to practical medical devices. Power sources must stay flexible and durable, which means developing thin-film supercapacitors and stretchable batteries that offer sufficient energy density.

Since these flexible power options often provide less energy than rigid batteries, you need to optimize power consumption and explore energy harvesting methods like flexible solar cells or biomechanical harvesters.

Manufacturing involves ensuring consistent print quality, reliable integration of stretchable conductors with rigid components, and cost-effective, scalable processes.

Biocompatibility requires using non-toxic, skin-friendly materials resistant to sweat and oils, with proper encapsulation to prevent chemical leaching.

Addressing these challenges is crucial to creating safe, reliable, and efficient stretchable electronic devices for real-world applications.

Emerging Trends and Future Prospects in Wearable Polymer-Based Electronics

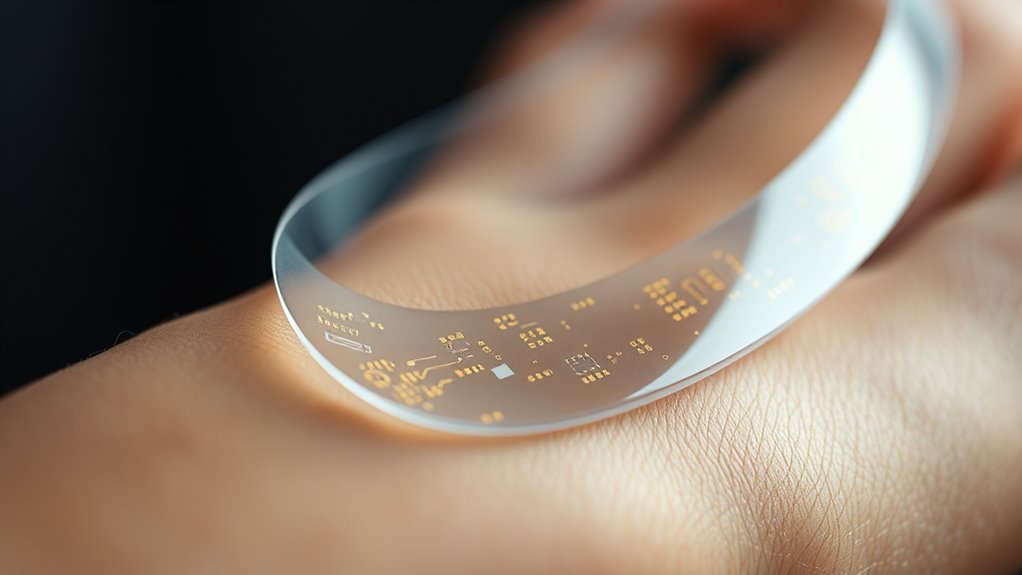

Emerging trends in wearable polymer-based electronics are transforming how you design and deploy flexible devices for healthcare, communication, and personal monitoring. Advances in organic polymers now enable efficient biological signal-to-electronic conversion, boosting device performance.

Bioresorbable electronics offer transient solutions that dissolve after use, reducing risks and waste. Liquid metal-polymer conductors, made with gallium-based metals, provide flexible, biocompatible sensing and therapy tools.

Two-dimensional materials are scalable and adaptable, opening new fabrication possibilities. Innovations in flexible device integration allow wearables to seamlessly blend into clothing or skin.

Stretchable conductive polymers and multifunctional gels enhance device functionality. Coupled with 3D/4D printing and AI integration, these trends promise smarter, more sustainable wearable electronics for personalized healthcare and beyond.

Frequently Asked Questions

How Do Stretchable Electronics Ensure Long-Term Durability in Daily Use?

You can guarantee long-term durability by using stretchable electronics designed to distribute mechanical stress effectively. Incorporate features like micro-patterns, micro-holes, or 3D structures that adapt to movement, preventing cracks.

Use flexible, biocompatible materials that withstand repeated bending, stretching, and washing. Modular designs allow for easy repairs, while extensive testing under real-life conditions guarantees reliability.

Combining these strategies helps your device endure daily wear and tear reliably over time.

What Are the Environmental Impacts of Biodegradable Wearable Electronics?

Imagine tossing a worn-out shirt into the soil, knowing it’ll turn to compost in months. That’s what biodegradable wearable electronics do—they decompose naturally, reducing e-waste and pollution.

Data shows these devices lose 98% of strength in four months and break down in soil within months. They minimize toxic residues, use eco-friendly materials like graphene, and cut environmental impact—making your tech choices greener and more sustainable.

How Is Data Security Managed in Wireless Stretchable Health Devices?

You manage data security in wireless stretchable health devices by implementing strong encryption methods, ensuring data is protected during transmission.

You also use robust authentication protocols to restrict access, and regularly conduct security audits to identify vulnerabilities.

Additionally, you rely on secure key management and encrypted communication channels, like Bluetooth, to prevent hacking.

These measures help safeguard sensitive health information and maintain user privacy effectively.

Can Stretchable Electronics Be Integrated With Existing Medical Infrastructure?

You can integrate stretchable electronics with existing medical infrastructure by leveraging their conformal attachment to internal organs and skin, ensuring seamless data collection. Their low interfacial impedance improves signal quality, making them compatible with current diagnostic tools.

Long-term stability under physiological conditions allows reliable monitoring. Plus, wireless data transmission enables easy integration into healthcare systems, providing continuous, comfortable monitoring for patients and enhancing diagnostic and therapeutic capabilities.

What Are the Regulatory Hurdles for Clinical Adoption of Wearable Stretchable Devices?

Thinking of your wearable device as a bridge to healthcare, you face regulatory hurdles that can seem like a maze. You need to navigate data protection laws like GDPR, gain device certification, and meet regional standards.

Clinical trials require flexible designs and timely approvals, while labeling must be durable and compliant.

Staying ahead means engaging early with authorities and adapting to evolving regulations to turn innovation into trusted medical solutions.

Conclusion

You’re on the cusp of a revolution in wearable tech, where stretchable electronics become as seamless as a second skin. With innovative polymers and nanomaterials, you can expect devices that are more flexible, durable, and biologically compatible than ever before. Just like a chameleon adapts to its environment, these advancements will allow electronics to move with you, opening endless possibilities for healthcare, fitness, and beyond. The future of wearable tech is shaping up to be truly transformative.