The science of chewing gum shows how its polymer backbone creates a flexible, durable structure that shapes texture and elasticity. These polymers, including elastomers and plasticizers, influence chewiness and mouthfeel, while their surface properties affect flavor retention. Hydrophobic components control flavor release over time, ensuring a lasting taste experience. Advances in polymer chemistry now allow for better control of texture and flavor diffusion, so you’ll uncover even more about what makes gum both enjoyable and scientifically fascinating.

Key Takeaways

- The gum base’s polymer backbone, composed of elastomers, resins, and waxes, provides elasticity, durability, and texture.

- Polymer properties like chain length and cross-linking influence chewiness, tensile strength, and flavor retention during mastication.

- Hydrophobic components in the polymer matrix control the slow, sustained release of flavor compounds.

- Hydrophilic phases enable rapid flavor release initially, creating a dynamic tasting experience.

- Advances in polymer chemistry improve gum durability, flavor release control, and environmental safety.

Understanding the Composition of the Gum Base Polymer Backbone

The composition of the gum base polymer backbone is essential for determining the texture, elasticity, and overall chewability of chewing gum. You’ll find that synthetic elastomers like styrene-butadiene copolymers, such as SBR, form the core structure, providing stretchiness and resilience. Polyvinyl acetate chains add strength and cohesion, holding the gum together while allowing flexibility. Petroleum-derived polymers like polyethylene and waxes serve as plasticizers, softening the gum and enhancing its chewability. These components create a durable yet pliable network that ensures long-lasting flavor release and a satisfying bite. Understanding the different materials used helps explain how gum maintains its shape, texture, and ability to carry flavors during chewing.

How Polymer Properties Influence Gum Texture and Chewability

Polymer properties play an essential role in shaping the texture and chewability of gum. The type of polymer determines elasticity and flexibility—elastomers like polyisobutylene provide stretchiness, while synthetic polymers such as SBR enhance durability. Filtration techniques their hydrophobic nature helps prevent water absorption, maintaining structural integrity during chewing. The plasticizer ratio softens elastomers, balancing chewiness without making the gum sticky. Crystalline and amorphous phases create a blend of moldable and rebound properties, influencing how the gum feels. Longer chains and higher molecular weight increase tensile strength, making gum resistant to fragmentation. Chain flexibility affects softness, while branching and cross-linking alter elasticity and stress distribution. The polymer backbone structure also influences how flavor compounds are retained and released during mastication, affecting overall flavor longevity. Additionally, understanding the molecular structure of polymers can help in designing gum textures tailored for specific sensory experiences and performance. Together, these factors shape how the gum responds under pressure, affecting your overall chewing experience.

The Role of Hydrophobic and Hydrophilic Components in Flavor Release

Flavor release during chewing hinges on the interaction between hydrophobic and hydrophilic components within the gum. Hydrophobic flavors are embedded in the polymer backbone, dissolving slowly and providing a prolonged taste. In contrast, hydrophilic flavors reside in water-soluble phases, causing an initial burst of flavor as they’re released rapidly during early chewing.

The oil-water partition coefficient determines release rates: higher hydrophobicity means slower, extended flavor release, while hydrophilicity leads to quick flavor availability. Understanding the chemical properties of flavor compounds helps in designing better flavor release profiles.

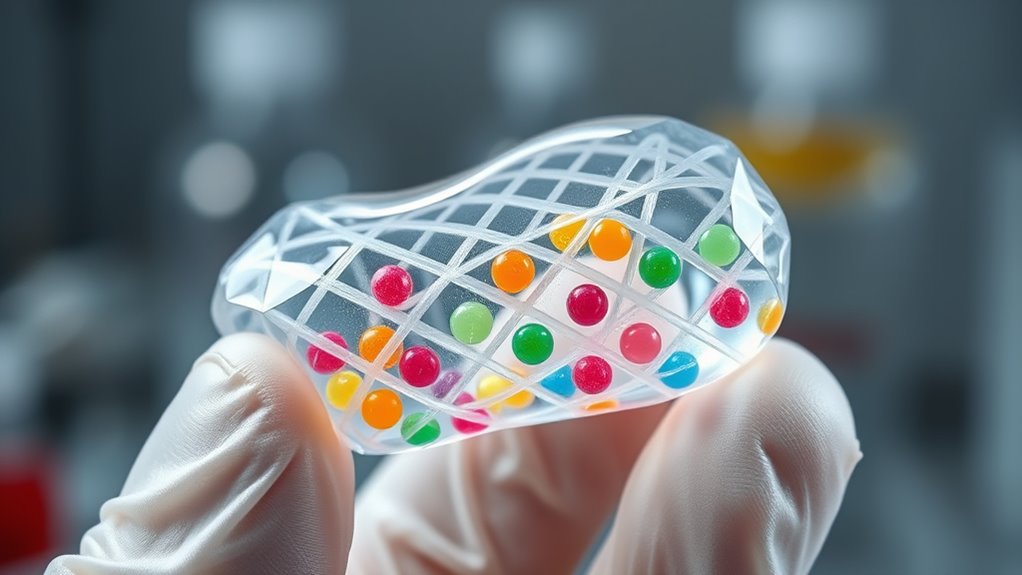

Encapsulation strategies involve hydrophobic flavorants inside hydrophilic shells, offering controlled release and protecting flavors from degradation. Adjusting shell hydrophobicity influences how fast flavors are released, allowing for tailored flavor profiles over time. Polymer structure plays a crucial role in modulating flavor release dynamics.

A comprehensive risk assessment of the flavor release process can help optimize the balance between hydrophobic and hydrophilic components for a consistent flavor experience. Balancing these components ensures a dynamic, lasting flavor experience during chewing.

Structural Features That Affect Gum Durability and Elasticity

Understanding what makes gum durable and elastic involves examining its structural features. The gum base contains key polymers like elastomers, resins, and plasticizers, each offering specific mechanical roles. Elastomers provide the stretchiness and recovery needed during chewing, while resins act as binders, maintaining the gum’s integrity. Vetted – Textile Line Plasticizers soften the base, increasing flexibility and reducing brittleness by adjusting the glass transition temperature. Waxes balance firmness and pliability, enhancing chewiness. The elasticity mainly comes from long polymer chains that stretch and return to their original shape, aided by temperature effects. Hydrophobic backbones repel water, preserving structural integrity despite prolonged chewing. The balance between elastic and plastic behaviors, along with additives like fillers and plasticizers, ultimately determines the gum’s durability and elasticity. Additionally, the specific polymer backbone composition influences how well the gum maintains its properties over time and under various conditions, especially considering the influence of polymer backbone chemistry on environmental stability.

Advances in Polymer Chemistry for Enhanced Gum Performance

Recent advances in polymer chemistry have revolutionized gum bases, enabling manufacturers to develop materials with improved chew resilience, softness, and stability. You now have access to synthetic elastomeric polymers that enhance mechanical properties and can withstand varied climates without losing texture or flavor.

Biocompatible polymers reduce health concerns linked to microplastic release, making gum safer. Tailored copolymers allow precise control over chain length and crosslinking, optimizing elasticity and durability.

Additionally, polymers with controlled hydrophobicity better interact with saliva, slowing degradation. Innovations include hybrid blends of synthetic and natural polymers, boosting performance while supporting sustainability.

These advancements also incorporate polymer additives, such as encapsulants and carriers, to improve flavor retention and release, ensuring a longer-lasting, more enjoyable chewing experience.

Designing Polymers for Controlled Flavor Diffusion and Duration

The composition and structure of the polymer matrix play a pivotal role in controlling how flavors are retained and released in chewing gum. By adjusting blend ratios of biodegradable polymers like polylactic acid (PLA) with natural gums, you can influence mechanical strength and diffusion rates.

Adding plasticizers modifies water absorption and improves homogeneity, helping to fine-tune flavor release kinetics. The chemical resistance of the matrix guarantees flavor stability in saliva-like conditions.

Achieving uniform distribution of polymer components promotes consistent flavor diffusion and prolongs flavor perception. Additionally, controlling polymer crystallinity and cross-link density impacts molecular mobility, enabling you to design gum that sustains flavor release over desired durations.

This strategic polymer engineering enhances both functionality and consumer satisfaction.

Impact of Polymer Architecture on Consumer Experience and Satisfaction

Polymer architecture directly influences how your chewing gum feels and performs, shaping your overall experience. Cross-linked chains provide reversible deformation, offering that familiar “chew” sensation. Too much cross-linking makes the gum stiff, causing jaw fatigue, while the right balance mimics natural chicle’s stretchability.

Polymer architecture shapes gum’s feel—balance cross-linking for optimal stretch and chewability.

Temperature affects pliability; warm mouth conditions soften thermoplastic polymers, boosting flavor diffusion. Hydrophobic polymers prevent gum breakdown and control flavor release, but if they dominate, flavor may be incomplete, reducing satisfaction.

Adhesion to lips or teeth affects mouthfeel and retention time, influenced by the polymer’s surface properties. Ideal polymer design ensures a smooth texture, consistent chewing, and satisfying flavor duration.

Poor architecture can lead to undesired stickiness, reduced elasticity, or short-lived flavor, impacting your overall satisfaction.

Future Directions in Gum Base Polymer Development

Advances in polymer technology are shaping the future of gum base development, aiming to create more sustainable, versatile, and health-conscious products. You’ll see a focus on biodegradable polymers and plant-based materials reducing environmental impact and waste.

Innovations include integrating nanotechnology to enhance flavor release and developing hybrid polymers with hydrophobic and hydrophilic components for better performance. Researchers are blending polymers to customize texture and durability, while new synthesis techniques improve material properties.

Efforts also target functional gums infused with vitamins or dental care ingredients, catering to health-conscious consumers. Additionally, eco-friendly packaging and green manufacturing technologies are evolving to support sustainability.

These advancements aim to balance performance, consumer preferences, and environmental responsibility, shaping a future where gum products are smarter, greener, and more aligned with global sustainability goals.

Frequently Asked Questions

How Does Polymer Molecular Weight Influence Gum Chewability and Flavor Retention?

The current question explores how polymer molecular weight affects gum chewability and flavor retention. You should know that higher molecular weight polymers make gum more elastic and stretchable, allowing for better chewability and larger bubbles.

They also help retain flavor longer by reducing porosity and controlling diffusion. Conversely, lower molecular weights can make gum firmer and less pliable, impacting overall enjoyment and flavor longevity.

Can Polymer Backbone Modifications Improve Environmental Biodegradability of Chewing Gum?

You can improve the environmental biodegradability of chewing gum by modifying its polymer backbone. Incorporating biodegradable polymers like polyesters or introducing bonds such as esters or carbonates makes the gum break down more easily in nature.

These modifications allow the gum to degrade faster under environmental conditions, reducing pollution and litter. However, you’ll need to balance these changes to maintain the gum’s chewability, flavor retention, and shelf life.

What Role Do Crosslinking Density and Polymer Branching Play in Flavor Release Control?

You might think crosslinking density and polymer branching directly control flavor release, but they mainly influence the gum’s structure and texture. Crosslinking makes the polymer network more rigid, while branching alters texture and flavor encapsulation.

However, flavor release is primarily affected by the gum’s composition, especially the balance between hydrophilic and hydrophobic phases, as well as flavor encapsulation techniques. These factors have a more direct impact on how flavors are perceived during chewing.

How Do Different Monomer Combinations Affect the Elasticity and Resilience of Gum Base?

You should know that different monomer combinations directly influence your gum’s elasticity and resilience. Using synthetic monomers makes the gum more uniform and durable.

Blending natural ones can create softer textures. Adjusting these ratios allows you to customize how the gum feels and lasts during chewing.

Are There Innovative Polymer Designs That Enhance Gum’S Mouthfeel and Sensory Appeal?

You can find innovative polymer designs that boost gum’s mouthfeel and sensory appeal by incorporating thermoplastic elastomers, which make the gum more flexible and enjoyable to chew. These advanced materials also improve flavor release, delivering a richer taste experience.

Additionally, modifications in polymer structure allow for diverse textures, enhancing overall mouthfeel. By choosing products with these cutting-edge polymers, you get a more satisfying, flavorful, and enjoyable chewing experience.

Conclusion

By understanding how the polymer backbone and its components influence flavor release and texture, you can see how gum makers craft a better chew. Imagine trying a new gum that stays flavorful longer, like a recent breakthrough where scientists redesigned the polymer structure for extended taste. This shows how advances in polymer chemistry directly enhance your chewing experience, making each bubble more enjoyable and satisfying. The future of gum looks tastier and more durable than ever.