Bananas turn brown mainly because of enzymatic browning, which happens when enzymes like polyphenol oxidase (PPO) react with oxygen inside the fruit. When the peel or flesh is damaged, these enzymes produce dark pigments called melanins, causing discoloration. Ethylene gas speeds up ripening and browning, especially when in contact with other ripening fruits. Understanding this process can help you better manage banana browning, so explore further to learn how to delay or prevent it.

Key Takeaways

- Bananas brown mainly due to enzymatic browning caused by the enzyme polyphenol oxidase (PPO).

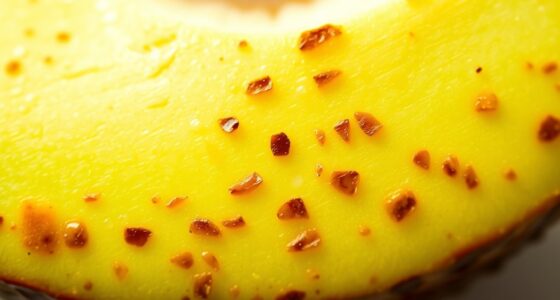

- When damaged or exposed to oxygen, PPO catalyzes phenolic compounds into brown melanin pigments.

- Ripening and ethylene gas increase PPO activity, accelerating browning.

- Bruising and cellular damage expose phenols and enzymes to oxygen, speeding up discoloration.

- Proper storage and handling can slow enzymatic browning by limiting oxygen exposure and enzyme activity.

What Causes the Browning in Bananas?

Bananas turn brown mainly because of a natural process called enzymatic browning, which is triggered by the production of ethylene gas. When bananas ripen, they produce ethylene, a plant hormone that speeds up ripening and browning. This gas causes enzymes within the fruit to react with oxygen, leading to the formation of brown pigments.

Storing bananas with other ethylene-producing fruits like apples or tomatoes accelerates this process. Environmental factors, such as cold temperatures, can also stress the fruit, increasing ethylene production and browning. Additionally, bruising damages the banana’s tissue, prompting more ethylene release.

As the banana ripens, starch converts to sugar, making the fruit more prone to browning. Overall, ethylene production and the ripening process are central to why bananas turn brown.

The Role of Enzymes in the Browning Process

Enzymes play a crucial role in the browning process by acting as biological catalysts that speed up chemical reactions without being consumed. They do this by lowering the activation energy needed for reactions, allowing browning to happen quickly once triggered. In bananas, the main enzyme involved is polyphenol oxidase (PPO), which catalyzes the oxidation of phenolic compounds into o-quinones. These quinones then polymerize into brown melanins, causing discoloration. Enzymes require specific conditions like oxygen, substrate availability, and proper pH to function effectively. When you cut or bruise a banana, cellular damage exposes phenols and PPO to oxygen, accelerating the reaction. The activity of these enzymes directly influences how fast and intense the browning appears, impacting the fruit’s appearance and quality. Additionally, enzyme activity regulation can be used to develop methods to slow or prevent discoloration in fruits. Understanding enzymatic browning is important for developing methods to slow or prevent discoloration in fruits.

How Polyphenol Oxidase (PPO) Contributes to Browning

Polyphenol oxidase (PPO) plays a central role in the browning process by catalyzing the oxidation of phenolic compounds into quinones, which then polymerize into dark pigments.

In bananas, PPO is a copper-containing enzyme that acts specifically on substrates with adjacent phenolic groups. When tissue damage occurs, cellular compartments break down, allowing PPO to contact phenolic compounds in the chloroplasts and vacuoles.

This contact triggers the enzymatic reaction, where PPO uses oxygen to convert phenols into reactive o-quinones. These quinones quickly polymerize into melanin-like pigments, causing the brown discoloration. The activity of PPO can be influenced by factors such as temperature and pH, which can either accelerate or slow down browning.

The process is rapid and visually impactful, reducing the fruit’s appeal and nutritional quality. Understanding enzyme activity helps explain how browning can be managed or slowed in some cases. Additionally, storage conditions such as temperature and pH can influence PPO activity and thus the browning rate, highlighting the importance of proper handling.

The Impact of Damage and Bruising on Enzymatic Activity

When a banana sustains physical damage or bruising, the disruption of its cellular structure triggers a series of biochemical changes that accelerate browning. Damage releases enzymes that promote enzymatic browning, while also increasing the production of ethylene gas, which speeds ripening and further browning. Fetal movements typically begin to be felt around 18-20 weeks, and similar to how enzymatic activity is affected by cellular damage, fetal activity can influence the health assessment during pregnancy. When cell membranes break apart, compounds are exposed to oxygen, facilitating oxidation reactions. The damage also alters pH levels, affecting enzyme activity, and causes chlorophyll breakdown, revealing yellow pigments that turn brown over time. Additionally, bruised areas become softer, making them more vulnerable to enzymatic reactions. As a result, brown spots or patches develop quickly on damaged parts, reducing visual appeal and shelf life. Handling bananas carefully and minimizing damage can help slow these browning processes.

Environmental Factors That Accelerate Browning

Environmental factors play a significant role in speeding up the browning process in bananas. Exposure to ethylene gas from nearby fruits accelerates ripening and increases polyphenol oxidase (PPO) activity, leading to faster browning. Ethylene gas is a plant hormone that influences various stages of fruit ripening, including enzymatic browning. Cold stress can also boost ROS levels, damaging cell components and triggering browning even when ripening slows down. High oxygen environments promote PPO activity, while modified atmospheres with low oxygen and higher CO2 slow enzymatic reactions and delay browning. Humidity levels influence peel integrity; improper moisture can make bananas more prone to browning. Additionally, banana variety and origin affect sensitivity to environmental stresses, with some cultivars browning faster due to genetic factors. Understanding enzymatic browning mechanisms can help in developing better storage strategies to minimize quality loss. For instance, controlling oxidative stress through environmental modifications can further slow down the browning process. Maintaining ideal storage conditions and controlling exposure to these environmental elements can help slow the browning process.

The Effect of Temperature and Humidity on Browning Rates

Temperature and humidity levels directly influence the rate at which bananas undergo enzymatic browning. Cold storage around 4ºC can increase browning by 2.6 times within 48 hours, but it may also cause chilling injury, triggering browning through cellular damage. Kia Tuning techniques, such as ECU remapping, highlight how environmental factors can be optimized to enhance performance and longevity—paralleling how storage conditions affect banana browning. Temperatures above 26.7ºC accelerate skin color changes and browning by increasing enzymatic activity and ethylene release. At 25ºC, bananas ripen with less browning, whereas at 40ºC, browning worsens due to stress and weight loss. Humidity also plays a vital role: maintaining 90-95% relative humidity reduces water loss, slowing browning, while low humidity stresses tissues and speeds up browning. When combined, temperature and humidity influence enzyme activity and cellular integrity, directly impacting how quickly bananas turn brown.

How Ethylene Production Influences Ripening and Browning

Ethylene production plays a central role in controlling how bananas ripen and develop browning. As a gaseous plant hormone, ethylene triggers ripening by increasing respiration and activating enzymes that soften the fruit and change its color.

Ethylene, a plant hormone, controls banana ripening and browning by triggering enzyme activity and color change.

During postharvest, bananas naturally produce more ethylene, accelerating ripening. Commercial facilities often apply ethylene to hasten this process, ensuring uniform ripening within days.

When exposed to external ethylene, bananas rapidly boost their internal ethylene and CO₂ levels, leading to faster biochemical changes. These include the activation of cell wall-degrading enzymes like pectinases and cellulases, which soften the fruit.

Ethylene also promotes chlorophyll breakdown, turning green peels yellow and signaling ripeness. However, excessive ethylene exposure can lead to over-ripening and increased browning susceptibility.

Techniques to Prevent or Slow Down Browning

To slow down browning in bananas, you can use various storage techniques and chemical treatments. Store unripe bananas at around 54°F (12°C) to delay ripening, but avoid colder temperatures that turn the peel black.

Keep bananas away from ethylene-producing fruits like apples and avocados, and hang them to prevent bruising.

Protect cut bananas by applying lemon juice or vinegar, which contain acids that inhibit enzyme activity. Cover slices with peanut butter or store them in airtight containers to limit oxygen exposure.

Freezing banana slices halts enzymatic activity, while blanching briefly in boiling water can also slow browning.

Handle bananas gently to prevent bruising, and use breathable packaging or paper bags to regulate moisture and ethylene gas, effectively extending freshness.

The Difference Between Enzymatic and Non-Enzymatic Browning

Understanding the key differences between enzymatic and non-enzymatic browning helps you better grasp how foods change color during storage and cooking.

Enzymatic browning involves enzymes like polyphenol oxidase that catalyze oxidation reactions, turning phenolic compounds into brown pigments. It mainly affects fresh fruits and vegetables exposed to oxygen, especially when tissues are damaged.

Non-enzymatic browning occurs without enzymes, mainly during heating, through processes like caramelization and the Maillard reaction. Caramelization involves sugar decomposition, while the Maillard reaction occurs between amino acids and reducing sugars, producing complex flavors and brown colors.

Control methods differ: enzymatic browning is slowed by deactivating enzymes, such as blanching, whereas non-enzymatic browning depends on heat, moisture, and pH.

These differences influence food appearance, flavor, and processing strategies.

Practical Applications and Research in Browning Prevention

Practical methods for preventing browning focus on both chemical treatments and storage techniques that maintain the appearance and quality of bananas.

Applying acidic treatments like lemon or pineapple juice immediately after cutting lowers pH and disrupts enzyme activity, slowing browning. Commercial anti-darkening agents such as Fruit-Fresh® are effective if used properly. Soaking bananas in diluted honey or immersing them in coconut water can also reduce browning and microbial growth.

Use lemon juice or coconut water immediately after cutting to slow browning and microbial growth.

Storage-wise, avoid sealed containers to ensure airflow, hang bananas to prevent bruising, and keep them away from ethylene-producing fruits. Storing bananas at room temperature in open air slows ripening without damaging texture. Wrapping stems with plastic reduces ethylene release, delaying browning.

Combining these practices helps preserve freshness and appearance during storage and handling.

Frequently Asked Questions

Can Enzymatic Browning Be Reversed Once It Occurs?

You wonder if enzymatic browning can be reversed after it happens. Generally, once quinones polymerize into melanin, the browning becomes irreversible.

However, if you act early, you might slow or prevent further discoloration using antioxidants like ascorbic acid, which reduce quinones back to phenols.

Physical methods, such as heat treatment or vacuum sealing, can stop enzyme activity, but they can’t undo browning that’s already set.

Do Different Banana Varieties Brown at Different Rates?

They say “timing is everything,” and that’s true for bananas. Yes, different varieties brown at varying speeds because of genetic differences and enzyme activities like PPO and POD.

Some varieties have lower enzyme activity, slowing browning, while others ripen faster and brown quicker. Storage conditions and ripening stage also influence this process.

How Do Preservatives Like Sulfur Dioxide Prevent Browning?

You might wonder how preservatives like sulfur dioxide prevent browning. When you add it, it acts as a nucleophile, attacking browning intermediates and inactivating enzymes like polyphenol oxidase.

It also binds to melanoidins, blocking oxidative reactions. Additionally, sulfur dioxide interferes with oxygen’s role, preventing oxidation.

This combination keeps your food looking fresh, light-colored, and appealing longer, making it a popular choice in food preservation.

Is Enzymatic Browning Harmful to Health?

Think of enzymatic browning as a double-edged sword—while it turns your fruit brown, it doesn’t pose health risks. You won’t get toxins or harmful substances from it.

Instead, the process mainly reduces nutrients like vitamin C and phenolics, which can slightly affect your nutritional intake. Overall, enzymatic browning isn’t harmful, but to preserve nutrients, you might want to use methods like antioxidants or acid treatments.

Can Genetic Modification Reduce Browning in Bananas?

Yes, genetic modification can reduce browning in bananas. You’d benefit from bananas that stay fresher longer because scientists disable the gene responsible for producing the enzyme polyphenol oxidase, which causes browning.

These non-browning bananas, developed with CRISPR technology, can last up to 12 hours after peeling. This innovation helps cut food waste, lowers environmental impact, and offers you more convenience and enjoyment from your bananas without worrying about quick spoilage.

Conclusion

Think of your banana as a once vibrant painting fading over time. Just as sunlight and air can dull colors, enzymes like PPO react with oxygen to cause browning, slowly transforming its appearance. By understanding this process, you hold the brush to prevent that dulling. With a few simple techniques, you can keep your banana’s picture fresh and lively longer, preserving its beauty before it fades into the background of everyday wear and tear.