Electrochemical ammonia synthesis has the potential to replace Haber-Bosch by producing ammonia at ambient conditions with lower energy use and minimal emissions, especially when powered by renewables. It offers scalable, decentralized manufacturing that reduces transportation and environmental impacts. While current efficiencies and catalyst stability need improvement, ongoing advancements show promise for industrial adoption. To understand how these developments could reshape ammonia production, explore the key processes, challenges, and future prospects outlined here.

Key Takeaways

- Electrochemical methods operate at ambient conditions, offering energy savings and environmental benefits over high-temperature Haber-Bosch.

- Current efficiencies and catalyst stability challenges limit large-scale adoption compared to mature Haber-Bosch technology.

- Electrochemical ammonia production enables decentralized, renewable-powered, small-scale plants, reducing transportation emissions and costs.

- Advances in catalyst design and mechanistic understanding are progressing toward achieving commercial viability.

- While promising, electrochemical ammonia is unlikely to fully replace Haber-Bosch in the near term but can complement existing processes.

Understanding Electrochemical Ammonia Synthesis

Have you ever wondered how ammonia can be produced efficiently at low temperatures without relying on traditional methods? Electrochemical ammonia synthesis achieves this by directly reducing atmospheric nitrogen (N₂) into ammonia (NH₃) at ambient or low temperatures, typically below 100°C. The process involves nitrogen dissociation on reactive catalyst surfaces, followed by proton and electron additions to form ammonia. Proton transport, often from water or electrolyte carriers, controls the reaction rate and selectivity. In lithium-mediated systems, non-aqueous electrolytes enable ion migration, creating unique nitrogen reduction pathways. The cycle completes with ammonia desorption from the catalyst surface, influencing overall yield and energy efficiency. This approach allows ammonia production under milder conditions, harnessing electricity to drive the reaction instead of high pressure and temperature. Electrochemical processes can be optimized to improve efficiency and scalability in sustainable ammonia synthesis. Additionally, advances in renewable energy integration are expected to further enhance the sustainability of this method.

How It Differs From Traditional Haber-Bosch Method

Unlike the Haber-Bosch process, electrochemical ammonia synthesis operates at much milder conditions, typically at or near room temperature and atmospheric pressure. This eliminates the need for high-temperature, high-pressure reactors and complex heat recovery systems.

While Haber-Bosch combines hydrogen and nitrogen in a catalytic reactor at extreme conditions, electrochemical methods produce ammonia directly from nitrogen and water within a single, low-temperature electrochemical cell. This reduces the number of process steps and allows for small-scale, distributed production, unlike the large, centralized Haber-Bosch plants.

Additionally, electrochemical processes use electrical energy directly, offering the potential for integration with renewable power sources. The development of electrochemical catalysts is crucial for improving reaction rates and overall efficiency in these systems. Furthermore, advances in renewable energy integration can help make electrochemical ammonia production more sustainable and cost-effective.

Benefits of Lower Energy Consumption and Environmental Impact

Electrochemical ammonia synthesis offers significant advantages in reducing energy consumption and environmental impact compared to traditional methods. It can use around 17 kWh per kilogram of NH3, far less than Haber-Bosch, especially with higher Faradaic efficiencies. Improving efficiency reduces energy needs further, and optimized systems can cut costs associated with ammonia separation. Additionally, advancements in Kia Tuning techniques demonstrate how targeted modifications can optimize systems for better performance and sustainability. Unlike Haber-Bosch, which consumes large amounts of fossil fuel energy, electrochemical methods powered by renewable electricity eliminate direct CO2 emissions. Localized, decentralized production also lowers transport emissions and allows more flexible energy sourcing. Additionally, water-based electrolysis can be more water-efficient, and waste generation is minimized with better catalyst use. These benefits make electrochemical ammonia a cleaner, more sustainable alternative for future fertilizer production.

Key Processes and Catalysts in Electrochemical Production

Understanding the key processes and catalysts involved in electrochemical ammonia production is essential for optimizing efficiency and selectivity. The process starts with nitrogen adsorption onto catalyst sites, which is pivotal for progress. Efficient nitrogen adsorption is crucial for the overall reaction rate and yield.

Next, nitrogen activation involves breaking the strong N≡N triple bond using electrons or protons, enabling ammonia formation. Proton-electron transfer then adds protons and electrons to the activated nitrogen, forming ammonia, which desorbs from the catalyst surface. The electrolyte plays an essential role by facilitating proton transport and maintaining a stable environment. Catalysts, typically transition metals or oxides, enhance reaction rates by increasing active surface area and improving nitrogen dissociation. Their stability and ability to balance nitrogen activation with proton transfer are key for advancing electrochemical ammonia synthesis under mild, ambient conditions. Additionally, understanding the Gold IRA tax implications and potential fees can help investors plan for sustainable funding of advanced technologies like electrochemical ammonia production. Recognizing the catalyst stability is vital, as it directly impacts the longevity and efficiency of the overall process.

Current Challenges and Limitations in Scaling Up

Scaling up electrochemical ammonia production faces significant hurdles, primarily due to energy efficiency limitations and catalyst stability issues. The maximum theoretical efficiency for Li and Ca-mediated methods hovers around 28%, far below the 60% target set by the US Department of Energy, and much less than Haber-Bosch’s 75%. Very negative cathode potentials hinder practical use, but developing catalysts stable at less extreme potentials could boost efficiency.

Currently, only certain cathode catalysts like Li and Ca produce ammonia at ambient conditions, yet designing catalysts that efficiently dissociate N₂ and release NH₃ remains tough. Scaling these systems demands maintaining performance and selectivity over time, managing heat and mass transfer, and overcoming high costs and material degradation.

These challenges slow progress toward viable, large-scale electrochemical ammonia production.

Role of Renewable Energy in Sustainable Ammonia Production

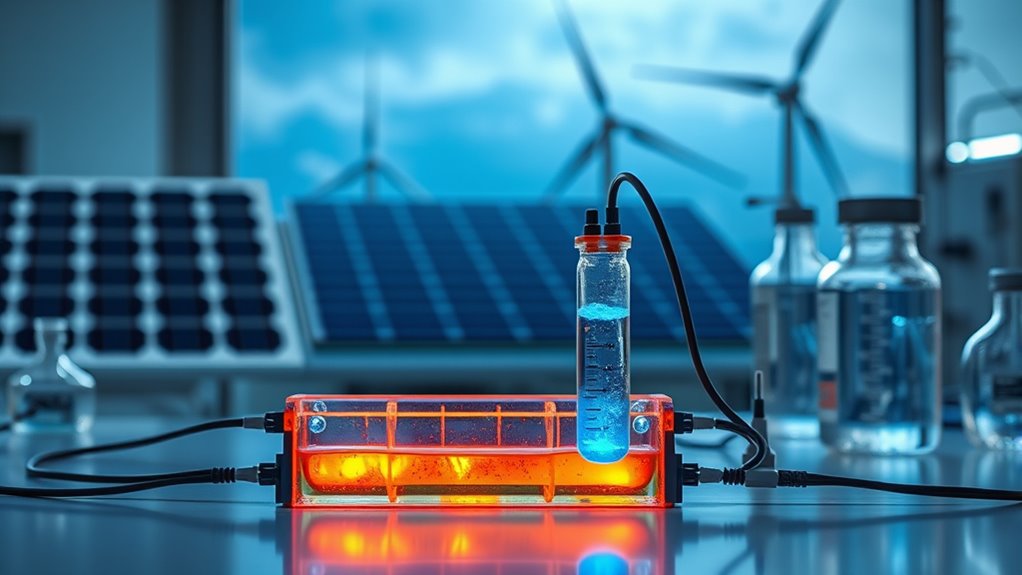

Integrating renewable energy sources transforms how you produce ammonia by making the process more sustainable and environmentally friendly.

By harnessing wind and solar power for electrolysis, you’ll generate hydrogen without emitting carbon, resulting in green ammonia. This approach reduces reliance on fossil fuels, helping you achieve zero-carbon status and lower greenhouse gas emissions.

Renewable hydrogen, combined with nitrogen extracted from the air, supports sustainable ammonia synthesis. It also stabilizes costs by avoiding fossil fuel price fluctuations, often making green ammonia cost-competitive below USD 100 per ton.

Retrofitting existing plants with renewable hydrogen further cuts expenses. Additionally, this shift opens new market opportunities, attracts investments, and promotes ecological preservation—driving decarbonization and supporting a cleaner, more resilient energy future.

Technological Advances Driving Efficiency Improvements

Recent technological breakthroughs are markedly enhancing the efficiency of electrochemical ammonia synthesis. Advances in catalyst development, like layered double hydroxide (LDH) materials, boost reaction kinetics and selectivity. Hybrid electrodes such as NiFe LDH/Cu foam improve ammonia yield by optimizing key steps like hydrogen radical generation, while electrode surface engineering enhances catalytic activity and stability.

Researchers aim for energy efficiency targets of at least 60%, challenging the Haber-Bosch efficiency of 75%. Process simplification reduces energy consumption by lowering operational complexity, and modular scalability allows for small-scale, renewable-compatible plants.

Ongoing mechanistic studies of N(_2) dissociation and ammonia desorption inform catalyst design, helping to overcome high polarization and energy barriers. These innovations collectively drive progress toward more efficient, cost-effective electrochemical ammonia production.

Potential for Decentralized and Localized Manufacturing

Decentralized ammonia manufacturing has the potential to transform supply chains by markedly reducing transportation costs—up to 76% in some cases—and improving regional availability. By producing ammonia closer to where it’s needed, you can lower distribution expenses and create more resilient, localized supply networks.

This approach also helps mitigate water stress by optimizing resource use at the regional level. Technological advances, like electrochemical synthesis, support flexible, small-scale production, making decentralization feasible.

It can boost local economies through job creation and skill development while reducing reliance on imported natural gas. Additionally, decentralized systems promote environmental benefits by enabling renewable energy integration, cutting emissions, and fostering sustainable practices.

Economic Factors and Market Readiness for Adoption

The economic viability of electrochemical ammonia hinges on electricity costs and market conditions. If electricity prices remain low, especially during periods of high renewable generation, you can produce ammonia profitably by aligning operations with low-cost electricity windows.

Real-time market fluctuations, like those seen in ERCOT, offer opportunities to optimize costs by operating mainly when prices dip.

Real-time market fluctuations enable cost optimization by targeting operations during low-price periods.

Compared to Haber-Bosh, which benefits from lower levelized costs but faces rising natural gas prices and carbon taxes, electrochemical methods could become more competitive as renewable electricity costs fall and carbon pricing increases.

However, current technologies are at pilot or early demonstration stages, limiting immediate market penetration. Supply chain development and scale-up are still underway, meaning full market readiness is a future goal rather than an immediate reality.

Future Outlook and Pathways Toward Industrial Implementation

Advancements in catalyst development, such as noble-metal nanostructures and boron-doped carbon, are paving the way for more efficient electrochemical ammonia synthesis by boosting Faradaic efficiency and selectivity.

Researchers are exploring non-aqueous electrolytes to increase nitrogen solubility and minimize hydrogen evolution, while lithium-mediated approaches show promise for higher yields at near-ambient conditions.

Integrating in-situ hydrogen production from water electrolysis can eliminate external hydrogen needs.

Pressure optimization studies highlight 0.7 MPa as effective, balancing energy input and conversion.

Renewable energy integration—especially coupling with solar or wind—offers sustainable power sources.

Hybrid systems and decentralized modular reactors can enhance scalability and flexibility.

Overcoming efficiency, durability, and scalability challenges will be critical for progressing electrochemical ammonia from lab to industry.

Frequently Asked Questions

What Are the Main Barriers to Commercializing Electrochemical Ammonia Production?

You face several barriers when aiming for commercial electrochemical ammonia production. The main issues include low production rates, high energy consumption due to overpotentials, and limited Faradaic efficiency.

Additionally, scaling systems cost-effectively is tough, and developing durable, efficient catalysts remains a challenge. You also need to overcome competing reactions like hydrogen evolution, all while ensuring system stability and managing high capital costs.

How Does Catalyst Durability Affect Long-Term Electrochemical Ammonia Synthesis?

Think of your catalyst as the engine of your electrochemical process—if it wears out, so does performance. Durability directly impacts your ammonia synthesis by maintaining high current density and efficiency over time.

When catalysts degrade, they lose active sites, reducing yield and selectivity. To keep production steady, you need stable catalysts that resist structural changes, poisoning, and morphological shifts, ensuring your process runs smoothly like a well-oiled machine.

Can Electrochemical Methods Produce Ammonia at Competitive Costs Today?

You wonder if electrochemical methods can produce ammonia at competitive costs today. Currently, it’s challenging because of high electricity and capital costs, plus the need for advanced reactor designs.

While costs could drop below $1/kg with improved efficiencies and scale, widespread commercial viability remains uncertain.

To succeed, you’ll need to focus on lowering energy expenses, enhancing process stability, and investing in innovative technology to compete with traditional Haber-Bosch methods effectively.

What Is the Environmental Impact of Scaling up Electrochemical Ammonia Plants?

Scaling up electrochemical ammonia plants impacts the environment mainly through increased land use for renewable energy infrastructure and resource extraction.

You’ll need sustainable materials for electrodes and electrolytes, and careful waste management to prevent pollution.

While it reduces greenhouse gases compared to traditional methods, you must also consider the lifecycle impacts of manufacturing, recycling, and energy sources to guarantee that expansion truly benefits the environment.

How Will Policy Changes Influence the Adoption of Electrochemical Ammonia Technology?

You’ll find that policy changes greatly influence how quickly electrochemical ammonia gains traction. Supportive policies, like emission reduction mandates and carbon pricing, incentivize adoption.

Governments that offer R&D funding, subsidies, and infrastructure investments make it easier for you to develop and implement cleaner technologies.

Clear regulations and international collaborations also boost confidence and standardization, encouraging you to shift towards sustainable ammonia production, ultimately accelerating the shift away from traditional methods.

Conclusion

Imagine a world where ammonia’s made in your backyard shed, not a giant factory churning pollution. Electrochemical methods promise just that—less energy, less fuss, and maybe even a smile from Mother Earth. But until your toaster starts producing fertilizer, don’t hold your breath. We’re still dialing in the tech, fighting scale-up gremlins, and debating if this fairy-tale can really replace Haber-Bosch. So, stay tuned—your future garden might just thank you.