Liposomes are spherical vesicles with phospholipid bilayers that can carry both water-soluble and lipid-soluble drugs, making them ideal for quick, targeted delivery. In contrast, lipid-based nanoparticles (LNPS) have a solid or semi-solid lipid core that provides stability and sustained release, especially for lipophilic drugs. Your choice depends on whether you need rapid action or long-lasting stability—exploring further will help clarify which system suits your needs best.

Key Takeaways

- Liposomes have a phospholipid bilayer with an aqueous core, suitable for water-soluble drugs, while LNPS have a solid lipid core ideal for lipophilic drugs.

- Liposomes enable quick fusion with cell membranes for rapid drug release; LNPS provide sustained, controlled release over time.

- Liposomes are sensitive to environmental factors like pH and temperature; LNPS offer greater stability and resistance to degradation.

- Liposomes can encapsulate both hydrophilic and hydrophobic drugs; LNPS primarily deliver lipophilic compounds effectively.

- Choice depends on drug properties and desired release profile: liposomes for targeted, rapid delivery; LNPS for long-lasting, stable delivery.

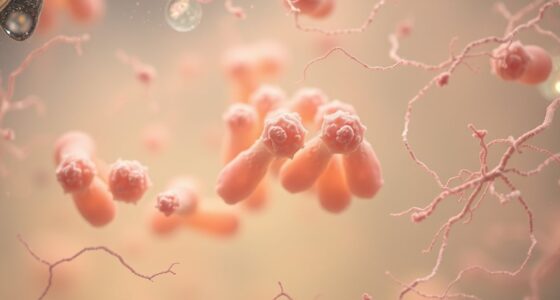

When choosing between liposomes and LNPS for drug delivery, understanding their fundamental differences is essential. Both systems function as carriers that enhance the delivery of therapeutic agents, but they do so through distinct structures and properties. Liposomes are spherical vesicles composed of phospholipid bilayers that enclose an aqueous core. They mimic cell membranes, making them highly biocompatible and capable of encapsulating both hydrophilic and hydrophobic drugs. LNPS, or Lipid Nanoparticle Systems, are more complex structures typically made from solid lipids stabilized by surfactants. They tend to have a solid or semi-solid core, which influences their behavior and stability in biological environments.

Choosing between liposomes and LNPS depends on drug properties and desired release profiles.

In terms of drug delivery, liposomes excel at delivering water-soluble drugs due to their aqueous interior, providing a protected environment that prevents premature degradation. They can fuse with cell membranes, facilitating direct drug release into target cells. However, their drug release profile can sometimes be unpredictable, which makes controlling the release rate a challenge in certain applications. LNPS, on the other hand, are especially effective for delivering lipophilic drugs. Their solid lipid core offers enhanced protection against enzymatic degradation and environmental factors, ensuring the drug remains stable until it reaches the target site. This makes LNPS particularly suited for sustained release formulations, allowing the drug to be released gradually over time.

Nanoparticle stability is a critical factor in selecting the appropriate delivery system. Liposomes can be sensitive to physical and chemical conditions, such as pH changes, temperature fluctuations, and serum components, which can cause leakage or rupture. To improve stability, researchers often modify liposomes with surface coatings or include cholesterol in the phospholipid bilayer. LNPS tend to exhibit superior nanoparticle stability because their solid lipid core resists degradation and maintains integrity under various physiological conditions. This stability reduces the risk of drug leakage during circulation and extends the shelf life of the formulation. Additionally, advancements in liposomal formulation techniques have contributed to improved stability and targeted delivery.

Ultimately, your choice hinges on the specific drug you’re delivering and the desired release profile. If rapid, targeted delivery of water-soluble drugs is your goal, liposomes may be more suitable. Conversely, if you need a stable, long-lasting carrier for lipophilic drugs, LNPS offer advantages in nanoparticle stability and controlled release. In either case, understanding these core differences allows you to select the most appropriate delivery vehicle for your therapeutic needs, ensuring maximum efficacy and safety.

Frequently Asked Questions

How Do Liposomes and LNPS Differ in Manufacturing Processes?

You’ll find that liposomes are typically produced through thin-film hydration or ethanol injection, which are relatively straightforward but may involve surface modification steps for targeting. LNPS manufacturing is more complex, often requiring high-pressure homogenization or microfluidization to guarantee uniform particle size. The production complexity of LNPS is higher, but it allows for better control over surface modification, enhancing stability and delivery efficiency compared to liposomes.

Which Delivery System Offers Better Stability Under Extreme Conditions?

You’ll find that LNPS generally offer better stability under extreme conditions, thanks to their enhanced thermal resilience and pH stability. Unlike liposomes, which can be sensitive to temperature fluctuations and pH changes, LNPS are designed to withstand harsh environments. This makes LNPS a more reliable delivery system when stability is critical, ensuring your formulations remain effective and intact even under extreme conditions.

Are There Specific Applications Where One Is Preferred Over the Other?

Think of liposomes as precise arrows for targeted delivery, making them ideal for vaccine adjuvants where pinpoint accuracy matters. You’d prefer LNPS when stability and controlled release are your priorities, especially in harsh environments. For applications like vaccines needing immune system stimulation, liposomes excel. Conversely, LNPS shine in delivering drugs that require sustained release, ensuring your payload reaches its destination intact and effective, no matter the journey.

How Do Cost and Scalability Compare Between Liposomes and LNPS?

You’ll find liposomes generally have higher costs due to complex manufacturing processes, making them less cost-efficient at large scales. LNPS, on the other hand, offer better scalability and cost efficiency because their production involves simpler, more adaptable methods. However, scalability challenges can still arise with both, especially when scaling up for industrial use, but LNPS tend to be more suitable for large-scale applications due to their streamlined production.

What Are the Environmental Impacts of Producing Each Nanoparticle Type?

You should consider that producing liposomes and LNPS impacts the environment differently. Liposomes often use biodegradable phospholipids, reducing biodegradability concerns, but their manufacturing can have a larger ecological footprint due to high energy use. LNPS, typically made from solid lipids, may have a smaller ecological footprint but raise concerns about biodegradability. Overall, both require careful assessment to minimize environmental impacts and address biodegradability concerns effectively.

Conclusion

In short, understanding the differences between liposomes and LNPS helps you make smarter choices in drug delivery. Liposomes are versatile but less stable, while LNPS offer better stability and controlled release. Remember, not all that glitters is gold; choosing the right nanocarrier depends on your specific needs. By knowing their strengths and weaknesses, you’re better equipped to navigate your options and avoid pitfalls. Stay informed, and don’t put all your eggs in one basket.