The rotovap revolutionized labs by making solvent removal faster, safer, and more efficient. With its unique design, you can control temperature, vacuum, and rotation speed to protect your samples and reduce waste. It simplifies complex processes, saving you time and effort while enabling solvent recovery for cost savings. As this technology becomes essential in modern labs, you’ll discover how its versatility improves research and production. Keep exploring to see how it continues to shape scientific workflows.

Key Takeaways

- Rotary evaporation automates solvent removal, increasing efficiency and safety compared to traditional methods.

- Its adjustable parameters allow precise control, ensuring high-quality and consistent lab results.

- The device’s ability to recover and reuse solvents reduces waste and environmental impact.

- Rotovaps significantly shorten drying times, accelerating research and production workflows.

- Their versatility makes rotary evaporation an essential, reliable tool in modern scientific laboratories.

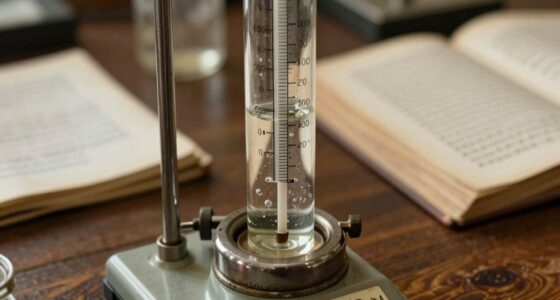

Have you ever wondered how modern laboratories achieve efficient solvent removal with such ease? The answer lies in the innovative use of rotary evaporation, or rotovap, a device that has transformed how scientists handle solvent recovery and concentration techniques. This technology streamlines processes that once took hours or even days, making lab work faster, safer, and more reliable. At its core, a rotovap offers a controlled environment where you can gently remove solvents from a mixture, leaving behind the desired compound without degrading it. It’s this ability to precisely control temperature and vacuum levels that makes the device so effective for concentration techniques, where maintaining the integrity of sensitive substances is critical.

Rotovaps enable precise, efficient solvent removal, making lab processes faster, safer, and more eco-friendly.

When you employ a rotovap, you essentially harness its design to recover solvents efficiently. Instead of pouring off liquids or evaporating solvents manually, you set the apparatus to rotate a flask containing your sample in a heated water bath under reduced pressure. The rotation increases the surface area of the liquid, speeding up evaporation while minimizing the risk of bumping or splattering. As the solvent vaporizes, it’s drawn into a condenser, where it cools and returns to a liquid state, ready to be collected or reused. This process not only conserves valuable solvents but also reduces waste, making your lab more environmentally friendly and cost-effective.

The key to the rotovap’s success in solvent recovery and concentration techniques is its precision. You can adjust parameters like temperature, rotation speed, and vacuum pressure to optimize each run. For example, if you’re working with heat-sensitive compounds, you can lower the temperature to prevent degradation. If you need faster evaporation, increasing rotation speed enhances surface contact, accelerating solvent removal. These adjustable settings give you control, ensuring you achieve consistent, high-quality results every time.

Furthermore, the efficiency of rotary evaporation means you spend less time waiting for your samples to dry or concentrate. This quick turnaround is especially valuable in research and industrial settings, where time is money. The ability to recover solvents for reuse also cuts costs and minimizes environmental impact, aligning with sustainable lab practices. Additionally, the importance of a high contrast ratio in the clarity and depth of images cannot be overstated, especially in visual analysis. As a result, the rotovap has become a staple in countless laboratories, replacing older, less efficient methods of solvent removal. Its versatility and reliability make it indispensable for chemists, biochemists, and pharmaceutical scientists alike, revolutionizing how labs approach solvent recovery and concentration techniques.

Frequently Asked Questions

What Are the Safety Precautions for Operating a Rotovap?

When operating a rotovap, you should always wear safety gear like gloves, goggles, and a lab coat to protect yourself. Make sure you’re familiar with emergency procedures in case of leaks, spills, or equipment failure. Keep the area well-ventilated, and never leave the device unattended while it’s running. Regularly inspect the apparatus for cracks or damage, and follow all manufacturer guidelines to guarantee safe and efficient operation.

How Does Solvent Choice Affect Rotary Evaporation Efficiency?

They say, “You get what you pay for,” and this applies to solvent choice in rotary evaporation. Selecting a solvent with appropriate polarity ensures an ideal evaporation rate, boosting efficiency. Non-polar solvents evaporate faster but may require careful handling, while polar solvents provide gentler evaporation. Your choice directly impacts the process, so consider solvent boiling points and compatibility to maximize lab productivity and safety.

Can Rotovaps Be Used for Temperature-Sensitive Compounds?

Yes, you can use rotovaps for temperature-sensitive compounds. They offer temperature stability by allowing precise control of the bath temperature, which helps prevent overheating. This control guarantees your compound’s integrity remains intact during evaporation. By adjusting parameters carefully, you minimize thermal degradation, making rotovaps suitable for delicate, temperature-sensitive substances. Always monitor the temperature closely to maintain ideal conditions and protect your valuable compounds.

What Maintenance Is Required for Long-Term Rotovap Use?

Like a finely tuned orchestra, your rotovap needs regular calibration procedures to guarantee optimal performance. You should routinely check and adjust temperature and vacuum settings, and replace seals when they show signs of wear to prevent leaks. Keeping the glassware clean and inspecting the motor and condenser also help maintain efficiency. With consistent maintenance, your rotovap stays reliable, delivering precise results over the long term.

Are There Cost-Effective Alternatives to Traditional Rotovaps?

Yes, you can find budget options and DIY solutions as alternatives to traditional rotovaps. Consider using simple distillation setups or repurposed equipment that can achieve similar results at a lower cost. While these options may require more manual effort and caution, they’re effective for small-scale or occasional use. Just guarantee safety is your priority, and research thoroughly to adapt DIY solutions appropriately for your specific needs.

Conclusion

Imagine the gentle hum of the rotovap, quietly transforming your lab work into a seamless dance. As you watch the swirling liquid evaporate smoothly under the glass, it’s clear how this device revolutionizes your workflow. With every rotation, you’re stepping into a future where precision and efficiency blend effortlessly. The rotovap isn’t just a tool — it’s your partner in discovery, turning complex processes into a fluid, almost mesmerizing, symphony of science.