3D printing in chemistry lets you customize lab equipment, create complex reaction devices, and develop specialized sensors and porous materials tailored for various applications. It speeds up manufacturing, reduces costs, and enables rapid prototyping of microreactors, chemically active structures, and educational models. You can design multifunctional tools with precise features that improve process control, safety, and efficiency. To discover how these innovations are reshaping labs and manufacturing, explore further.

Key Takeaways

- 3D printing enables rapid prototyping of complex laboratory equipment, reducing development time and costs.

- It allows customization of microreactors and reaction modules for precise chemical process control.

- 3D-printed sensors and porous materials improve detection, separation, and catalytic applications in chemical and biomedical fields.

- Modular, multi-material models enhance understanding of molecular structures and mechanisms in educational settings.

- Customized, durable lab tools and implants can be produced efficiently, advancing manufacturing and healthcare applications.

Advancing Molecular Modeling With 3D Printing

3D printing has revolutionized molecular modeling by providing tangible, accurate representations of complex biological structures. You can now visualize virus capsid self-assembly through detailed atomic models, helping you study molecular dynamics directly. This hands-on approach enhances comprehension of intricate processes that are difficult to grasp through two-dimensional images alone. Protein folding mechanisms become clearer as you manipulate modular parts that mimic conformational changes. With multi-material printing, you achieve precise DNA structures, highlighting base-pairing interactions. Multicolor models depict molecular orbitals, illustrating electron density and bonding, making abstract concepts concrete. You can also explore enzyme cofactors by examining catalytic active sites and substrate interactions physically. These models serve as powerful educational tools, offering low-cost, hands-on learning experiences. They enable you to understand molecular geometry, assembly, and function more intuitively, bridging the gap between theoretical knowledge and tangible understanding. The ability to create accurate models is a breakthrough that significantly enhances scientific education and research.

Customizing Laboratory Equipment for Precision Experiments

Building on the advancements in molecular modeling, customizing laboratory equipment with 3D printing allows you to tailor tools precisely to your experimental needs. You can rapidly prototype designs using CAD software, reducing development time and costs. Design flexibility also enables the creation of unique, complex geometries that traditional manufacturing cannot achieve, further expanding experimental possibilities.

Leverage 3D printing to quickly prototype and customize laboratory tools, enhancing precision and efficiency in your experiments.

This flexibility lets you create bespoke tools that enhance accuracy and functionality. The ability to quickly iterate designs means you can make real-time adjustments without delays.

With various materials available, you can produce equipment with specific durability, weight, and chemical resistance suited to your experiments. Custom designs can incorporate complex functionalities and ergonomic features, improving user experience.

This customization streamlines workflows, cuts costs, and boosts productivity. By designing tools tailored to your environment, you ensure higher precision, better organization, and more efficient laboratory operations. 3D printing technology continues to evolve, opening new possibilities for innovative laboratory solutions.

Enhancing Complex Molecule Synthesis Through 3d-Printed Devices

Leveraging 3D-printed devices substantially enhances the synthesis of complex molecules by enabling precise customization of reaction environments and flow systems. Using tools like ChemSCAD, you can create digital reactors tailored to specific chemical steps, improving reproducibility and precision. ChemSCAD’s digital library of verified, reaction-specific designs facilitates rapid deployment and iterative optimization of reaction setups. Connecting multiple printed reactors allows continuous, multistep synthesis, reducing manual handling and contamination risks. Microfluidic devices with customizable geometries optimize mixing and reaction conditions, while nanoscale channels ensure precise reagent delivery. Incorporating catalysts and sensors directly into printed channels offers better control over reaction kinetics and monitoring. Additionally, 3D printing enables the fabrication of custom reaction chambers with improved mass transfer and heat management. This approach aligns with the principles of offensive security measures to enhance experimental control and reliability. Combining these innovations accelerates complex molecule development, streamlining workflows and enabling rapid prototyping for advanced synthetic processes.

Developing Specialized Chemical Sensors via Additive Manufacturing

The use of additive manufacturing techniques has opened new avenues for creating highly specialized chemical sensors tailored to specific analytical needs. You can print electrodes directly into sensor structures using conductive materials like carbon-loaded PLA, enabling integrated electrochemical functionality.

By combining multiple materials, such as non-conductive and conductive filaments, you can design complex geometries, including microfluidic channels and multi-electrode arrays, with ease. Gold electroplating enhances conductivity, corrosion resistance, and durability without high costs.

Fused deposition modeling (FDM) allows rapid, precise prototyping, reducing assembly steps and speeding up production. This flexibility supports miniaturization, customization, and functional integration, enabling you to develop sensitive sensors with lower detection limits, broader sensing ranges, and improved reproducibility.

Additionally, understanding filter replacement indicators can help ensure consistent sensor performance and longevity. These sensors are ideal for environmental monitoring, biomedical diagnostics, and quality control applications.

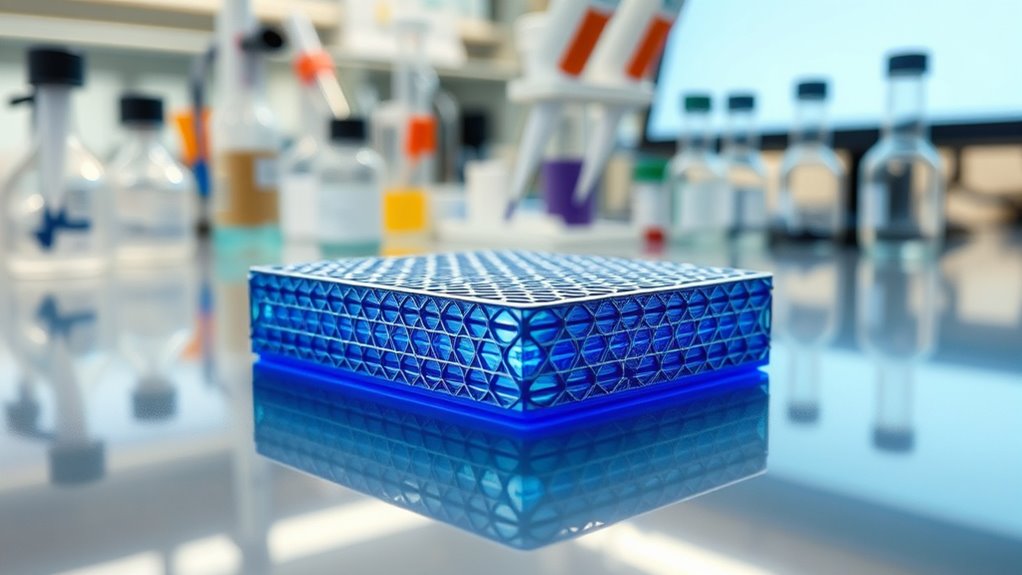

Creating Tailored Porous Materials for Diverse Chemical Applications

Additive manufacturing offers precise control over the geometry and internal structure of porous materials, enabling you to tailor pore size, shape, and interconnectivity beyond traditional methods. With techniques like direct ink writing and digital light processing, you can create complex porous structures with tunable porosity and customizable features.

By adjusting filler types and concentrations, you control porosity levels between 40-73 vol %, affecting properties like elasticity and strength. Embedding conductive materials or secondary polymers allows you to modify mechanical and electrical behaviors. Additionally, understanding gear shifting techniques helps optimize the handling of materials during manufacturing processes.

These tailored porous materials serve as catalyst supports, gas separation membranes, or reactive substrates, improving efficiency and selectivity. This flexibility opens new possibilities for designing functional materials that meet specific chemical process needs, enhancing performance in both laboratory and industrial applications.

Supporting Educational and Research Initiatives With 3D Models

Supporting educational and research initiatives with 3D models transforms how students and scientists understand complex chemical concepts. You can use 3D printing to create detailed molecular structures, making abstract ideas more tangible. Interactive models allow students to manipulate molecules, deepening their comprehension of chemical bonding and interactions. Additionally, incorporating visualization techniques can further enhance understanding by providing dynamic views of molecular processes. These tools are increasingly accessible and customizable, enabling educators to tailor lessons to specific topics and boost engagement—all while keeping costs low. In labs, 3D printing facilitates the development of specialized equipment, such as custom reactors and open-source devices, speeding up prototyping and innovation. It also promotes interdisciplinary collaboration, combining expertise from chemistry, design, and engineering. Overall, 3D printing enhances learning experiences and accelerates research by providing versatile, affordable, and tailored tools.

Improving Chemical Process Control With Microfluidic and Reaction Chambers

Microfluidic and reaction chambers revolutionize chemical process control by providing precise management of reaction conditions. You can accurately regulate flow rates with programmable pumps or pressure controllers, ensuring ideal reagent mixing and timing.

Controlling residence time and flow path geometry allows fine-tuning of reaction kinetics, leading to better yields. Integrated thermal elements maintain uniform temperature gradients, enhancing reaction consistency and selectivity.

Optimizing residence time and flow paths enhances reaction control, yield, and selectivity through precise thermal management.

These platforms support multiple reagent inputs with high precision, overcoming complexity in multi-component reactions. The small volumes and efficient heat dissipation make handling reactive intermediates safer and improve process stability.

Microreactors outperform traditional batch reactors in efficiency, minimizing side reactions and impurities. Their rapid mixing, high surface-to-volume ratio, and integration of reaction and analysis steps streamline real-time monitoring, boosting chemical synthesis precision and safety.

Innovating Material Development for Medical and Engineering Uses

Advancements in 3D printing are driving innovative material development for medical and engineering applications, enabling the creation of highly specialized and functional materials. You can now design biomimetic materials that mimic biological systems, improving their performance in medical devices and engineering structures. Inspirational quotes can serve as a source of motivation and insight for researchers pushing the boundaries of material science. Personalized pharmaceuticals can be produced with tailored properties, enhancing treatment efficacy. Programmable, sophisticated materials allow for new functionalities, while composite materials combining polymers and conductive agents expand applications like sensors and electrochemical cells.

Researchers are also developing porous, chemically active materials for microextraction and lab tools. These innovations enable the production of custom implants, tissue scaffolds, and durable components, revolutionizing healthcare and engineering fields by offering adaptable, high-performance materials tailored to specific needs.

Frequently Asked Questions

What Materials Are Compatible With 3D Printing for Chemical Applications?

You should consider materials like polypropylene, nylon, PEEK, PTFE, PVC, and PVDF for chemical applications because they resist corrosion and solvents well.

Polycarbonate, TPU, PETG, ASA, and ABS are suitable for less aggressive environments.

For specialized needs, metals and ceramics provide durability and chemical inertness.

When selecting materials, prioritize chemical compatibility, temperature stability, and mechanical properties to guarantee your 3D printed parts perform reliably in chemical settings.

How Does 3D Printing Impact the Cost of Laboratory Equipment?

Imagine you’re stepping into a future where 3D printing revolutionizes labs. It markedly cuts costs by enabling you to produce custom equipment on demand, saving money on outsourcing and expensive parts.

You can use affordable materials like PLA, making in-house manufacturing feasible. Plus, automation reduces labor costs, and rapid prototyping accelerates research.

Can 3d-Printed Models Accurately Represent Dynamic Molecular Interactions?

You’re wondering if 3D-printed models can accurately show dynamic molecular interactions. While they excel at representing static structures with high precision, they struggle to depict the fluidity and transient nature of interactions like hydrogen bonds or electron movements.

However, innovations like embedded magnets and multi-material printing help simulate some dynamic aspects. Still, for full understanding, combining models with digital tools remains essential to capture molecular flexibility and reactions accurately.

What Are the Limitations of 3D Printing in Creating Functional Chemical Sensors?

Imagine you’re in the 21st century, yet 3D printing still faces hurdles creating functional chemical sensors. You’ll find limited material options, often just plastics that may not resist chemicals.

Costly printers, surface flaws, and size restrictions hinder performance. Reproducibility and long-term stability also pose challenges.

While advancements promise better resolution and materials, these limitations mean you must carefully consider design, materials, and post-treatment for reliable sensor development.

How Does 3D Printing Improve Safety in Chemical Research Environments?

You see that 3D printing enhances safety in chemical research by reducing hazardous material exposure through precise dispensing, enclosed chambers, and waste reduction.

It also controls emissions with built-in filtration and low-emission filaments. Additionally, automated workflows and safety protocols prevent errors.

While doing so, dedicated ventilation and PPE integration minimize risks. Overall, these innovations create a safer environment, protecting you from chemical hazards and ensuring better process control.

Conclusion

So, while 3D printing might seem like just a fancy gadget for geeks, it’s actually revolutionizing chemistry labs and manufacturing. Who would’ve thought that tiny, custom-built devices could replace expensive equipment and streamline experiments? It’s almost ironic—cutting-edge science now comes from a printer in your garage. Keep an eye on this tech; soon, you’ll be printing your way to groundbreaking discoveries, all while pretending you’re just fooling around with plastic.