The boom in hazardous-area electronics is mainly driven by intrinsically safe technology, which minimizes ignition risks in explosive environments. This approach limits energy in circuits, preventing sparks or excessive heat that could cause explosions. Companies prefer this safer, more streamlined solution over bulky enclosures, helping you install and maintain equipment more easily. As safety standards advance worldwide, understanding how intrinsically safe devices work will help you stay ahead in hazardous industry environments.

Key Takeaways

- Growing safety regulations drive demand for intrinsically safe electronics to prevent ignition risks in hazardous environments.

- Advances in technology enable compact, reliable intrinsically safe devices suitable for diverse industrial applications.

- International certifications like ATEX and IECEx promote global adoption of intrinsically safe equipment.

- Industry needs for efficient, safe communication and data collection in explosive areas fuel innovation in intrinsically safe tech.

- Increasing industry regulation and safety standards push the development and deployment of intrinsically safe solutions.

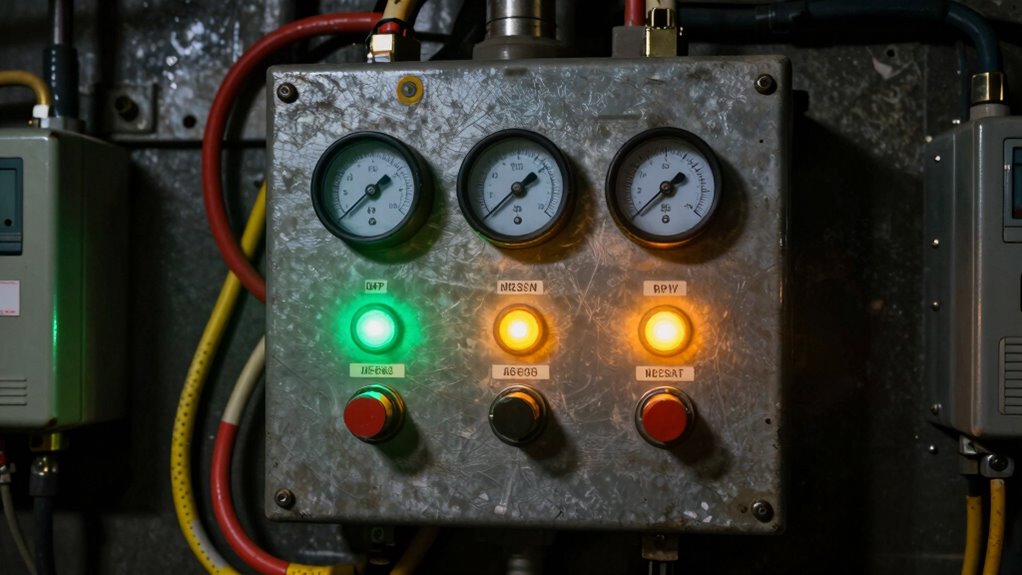

Have you ever wondered how electronic devices operate safely in environments with flammable gases or dust? When working in areas prone to explosive atmospheres, it’s vital that equipment doesn’t ignite these hazardous substances. This is where hazardous-area electronics come into play, specifically designed to prevent sparks or heat that could trigger explosions. The driving force behind these innovations is the strict enforcement of safety regulations, which mandate that equipment used in such environments must meet rigorous standards. These safety regulations are constantly evolving to keep pace with technological advancements, ensuring that devices don’t become sources of ignition.

You’ll find that intrinsically safe technology is at the heart of this shift. Intrinsically safe devices are engineered to operate with minimal energy, reducing the risk of sparks or excessive heat. When you use intrinsically safe equipment, you’re working within the parameters defined by safety regulations that specify maximum voltage, current, and power levels. These regulations are designed to limit the energy available in a circuit, so even if a fault occurs, it won’t produce enough energy to ignite an explosive atmosphere. As a result, you can confidently operate sensors, transmitters, or communication devices in environments where flammable gases or dust are present.

The growth of intrinsically safe electronics is driven by the need for reliable communication and data collection in hazardous locations. With industries like oil and gas, chemical processing, and mining expanding into more challenging environments, there’s a greater demand for electronics that can withstand these conditions without compromising safety. You’ll notice that manufacturers now develop compact, durable, and compliant devices that conform to safety standards like ATEX, IECEx, and UL. These certifications ensure that the equipment has been tested thoroughly to prevent ignition risks, aligning with safety regulations.

Moreover, the adoption of intrinsically safe technology not only enhances safety but also improves operational efficiency. You no longer need to install bulky explosion-proof enclosures for every device, which can be costly and cumbersome. Instead, intrinsically safe electronics allow for more streamlined, flexible setups that are easier to install and maintain. As safety regulations continue to tighten, the industry’s focus on intrinsically safe solutions will only intensify, pushing innovation forward. Additionally, advances in European safety standards are further promoting the adoption of these technologies across various hazardous industries.

Frequently Asked Questions

What Industries Most Benefit From Intrinsically Safe Electronics?

You’ll find that mining safety and chemical processing industries benefit most from intrinsically safe electronics. These sectors require equipment that prevents sparks and explosions in volatile environments. By using intrinsically safe devices, you guarantee safer operations, reduce risks, and comply with strict safety standards. This technology enables you to work confidently in hazardous areas, protecting both personnel and assets while maintaining productivity and regulatory compliance.

How Does Intrinsically Safe Technology Differ From Explosion-Proof Designs?

You’ll find intrinsically safe technology differs from explosion-proof designs mainly in approach. Intrinsically safe devices meet strict design standards and safety certifications by limiting energy to prevent sparks, rather than containing explosions like explosion-proof designs. This makes them safer and more suitable for sensitive electronic equipment in hazardous areas, ensuring compliance with industry standards while maintaining functionality. Their focus on controlling energy levels enhances overall safety in volatile environments.

Are There Cost Differences Between Intrinsically Safe and Standard Electronics?

Think of intrinsically safe electronics like a high-performance sports car designed for rough terrains. They often have a higher upfront cost due to specialized components, creating a cost variance compared to standard electronics. However, these expense implications can be offset by reduced risk of explosion and lower insurance premiums. Overall, while initial expenses may be higher, the safety and compliance benefits make them a worthwhile investment in hazardous areas.

What Future Innovations Are Expected in Hazardous-Area Electronics?

You can expect future innovations in hazardous-area electronics to focus on wireless integration and battery advancements. These developments will enable more reliable, real-time data transmission and longer-lasting, safer power sources. As technology progresses, you’ll see smarter, more efficient devices that enhance safety and operational efficiency in hazardous environments. This will make managing risks easier, while also reducing costs and downtime, ultimately transforming how you work in these challenging conditions.

How Do Regulations Impact the Development of Intrinsically Safe Devices?

You might think regulations hinder innovation, but they actually drive the development of intrinsically safe devices. Regulatory compliance and safety standards ensure devices meet strict criteria, fostering trust and safety in hazardous environments. They push manufacturers to innovate, creating smarter, more reliable solutions. While compliance adds some hurdles, it ultimately fuels advancements, guaranteeing devices protect users and environments effectively, and encouraging ongoing improvements in intrinsically safe technology.

Conclusion

You can see how the demand for hazardous-area electronics is skyrocketing, driven by the need for safety and innovation. Did you know that the market is expected to grow at a compound annual growth rate of over 8% through 2028? This growth underscores the importance of ‘intrinsically safe’ technology, ensuring safety without sacrificing performance. As industries expand into more challenging environments, embracing these advancements will keep your operations secure and compliant.