Process intensification makes chemical plants smaller and smarter by incorporating innovative reactor designs that boost efficiency, reduce resource use, and lower costs. These advanced reactors are more compact, promote better mixing, and improve heat transfer, enabling faster reactions at lower energy levels. They streamline operations, increase safety, and support sustainability efforts. With ongoing innovations, you’ll discover how these smarter systems are shaping the future of chemical manufacturing—keep exploring to learn more.

Key Takeaways

- Process intensification transforms traditional plants into smaller, more efficient facilities by integrating advanced reactor designs.

- Innovative reactors increase productivity while reducing equipment size, energy use, and operational costs.

- Technologies like microreactors and optimized heat transfer enable continuous processing at lower temperatures and pressures.

- Modeling and simulation facilitate reactor optimization, enhancing performance, safety, and sustainability.

- The approach leads to smarter, more flexible chemical plants that are cost-effective and environmentally friendly.

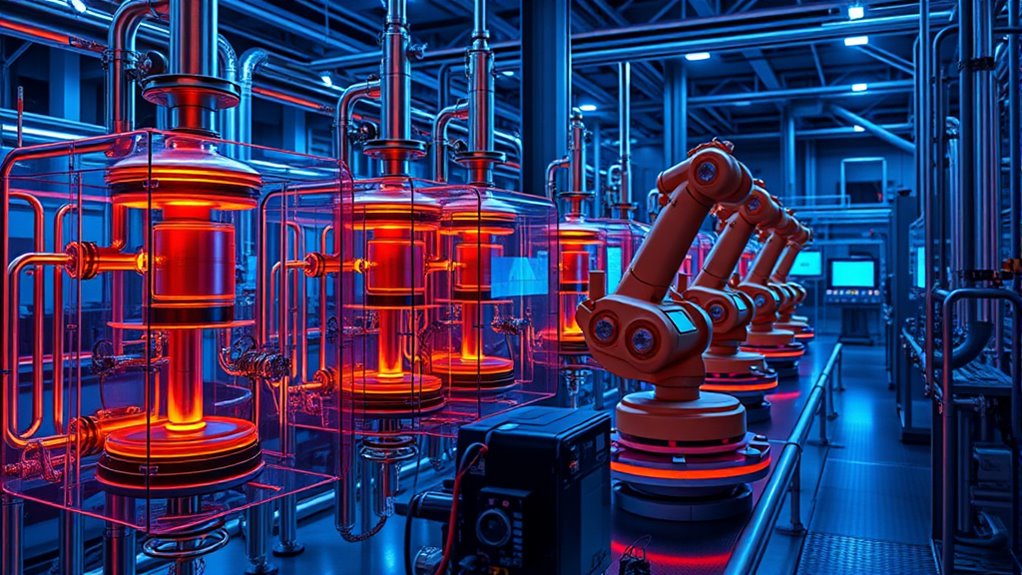

Have you ever wondered how industries can produce more efficiently while reducing costs and environmental impact? The answer lies in process intensification, a revolutionary approach that transforms traditional chemical plants into smaller, smarter facilities. At the heart of this innovation is reactor design, which plays a pivotal role in boosting energy efficiency. By rethinking how reactions occur, engineers develop compact, highly effective reactors that maximize output while minimizing resource consumption.

These advanced designs often integrate multiple functions into a single unit, reducing the need for extensive piping, heat exchangers, and auxiliary equipment. As a result, plants become more streamlined, with fewer components that can fail or require maintenance, ultimately lowering operational costs and downtime.

Integrated multi-function reactors simplify plant design, reduce maintenance, and lower operational costs.

The key to successful process intensification is creating reactors that not only enhance reaction rates but do so with minimal energy input. Improved reactor designs leverage principles like increased surface area, better mixing, and controlled heat transfer to achieve higher yields in shorter times. For example, microreactors and tubular reactors use innovative geometries to facilitate rapid heat transfer and uniform reactant distribution.

This means you can operate at lower temperatures and pressures, directly contributing to greater energy efficiency. Not only does this reduce the carbon footprint of the plant, but it also cuts energy costs considerably. These reactors also enable continuous processing, which is more efficient than batch methods, further improving productivity and energy use.

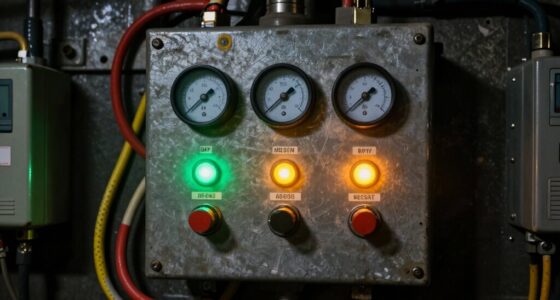

By adopting smarter reactor designs, industries can also enhance safety and flexibility. Smaller reactors are easier to monitor and control, reducing risks associated with high-pressure or high-temperature operations. They also allow for rapid adjustments to production parameters, making it simpler to switch between different products or respond to market demands.

This adaptability is an essential aspect of process intensification, helping plants stay competitive in an ever-changing landscape. Furthermore, advancements in reactor design are supported by computational modeling and simulation. These tools allow engineers to optimize reactor configurations before building them, ensuring maximum energy efficiency and performance.

Integrating color accuracy considerations into reactor design can also lead to improvements in product quality, especially in processes where visual indicators are important. The integration of process intensification principles into plant design results in facilities that aren’t just smaller, but also more intelligent—capable of producing higher-quality products with less waste and lower energy consumption. Overall, focusing on innovative reactor design is a critical step toward creating more sustainable, cost-effective chemical processes that meet the demands of modern industry.

Frequently Asked Questions

How Does Process Intensification Affect Overall Plant Safety?

When considering how process intensification affects overall plant safety, you’ll find it can improve hazard mitigation by reducing equipment size and complexity.

Smaller, smarter plants enable you to implement more effective safety protocols, monitor conditions closely, and respond swiftly to emergencies. This approach minimizes risks, enhances safety, and creates a safer working environment.

It also gives you greater control over hazards and ensures that safety measures are more efficient and reliable.

What Are the Economic Benefits of Smaller Chemical Plants?

Smaller chemical plants offer significant economic benefits by reducing costs and capital expenses. You can save money on construction, maintenance, and operation because compact designs require less space and materials.

These plants also enable quicker setup and easier upgrades, boosting efficiency. With lower capital investments, you can allocate resources more effectively, ultimately increasing profitability and competitiveness in the market.

Smaller plants make economic sense for many industry applications.

How Does Process Intensification Impact Environmental Sustainability?

Imagine a greener world where your actions ripple through nature’s fabric. Process intensification enhances environmental sustainability by promoting eco-friendly design and resource conservation.

You reduce waste and energy use, transforming large, polluting plants into smaller, smarter operations. This shift minimizes environmental impact, preserves natural resources, and fosters responsible innovation.

As you embrace these changes, you help build a sustainable future, proving that smarter processes can also be kinder to our planet.

What Industries Are Most Suited for Process Intensification?

You’ll find that industries like pharmaceuticals, fine chemicals, and specialty chemicals are most suited for process intensification. They benefit from modular design and resource efficiency, which allow for smaller, more adaptable plants.

What Are the Main Challenges in Implementing Process Intensification Technologies?

When tackling the main challenges in implementing process intensification technologies, you face scaling challenges and technology integration issues.

Scaling up small, efficient systems can be complex, requiring precise control and redesign.

Additionally, integrating new technologies into existing facilities demands careful planning, training, and investment.

You must overcome resistance to change and address compatibility concerns, ensuring that the innovations deliver benefits without disrupting current operations.

Conclusion

Just as Da Vinci envisioned transforming art and science, process intensification aims to revolutionize chemical plants—making them smaller, smarter, and more efficient. By embracing these innovations, you’re stepping into a future where complexity is tamed, and performance soars. Imagine the possibilities, like the alchemists of old turning base metals into gold—only now, you’re turning raw inputs into valuable solutions faster and greener. The future of chemical manufacturing is yours to shape.