To achieve ultra-high purity in microelectronics cleaning, focus on advanced techniques that remove microscopic nanoparticles and contaminants. Use tailored methods like plasma cleaning, ultrasonication, and specialized surfactants to guarantee surfaces stay free of residues and particles. Controlling surface wettability helps achieve thorough rinsing and residue-free drying. By combining these approaches, you’ll improve device performance and longevity. Staying informed about the latest cleaning strategies can help you optimize your processes further.

Key Takeaways

- Advanced cleaning techniques like plasma cleaning and ultrasonication effectively remove ultra-fine nanoparticles, ensuring high purity surfaces.

- Surface wettability control enhances rinsing effectiveness, preventing residue buildup and maintaining ultra-high purity levels.

- Tailored cleaning protocols minimize ionic contamination and water spots, critical for device reliability and longevity.

- Material selection and process optimization reduce microscopic residues, supporting defect-free microelectronic device fabrication.

- Implementing ultra-high purity cleaning strategies improves device yield, performance, and long-term operational stability.

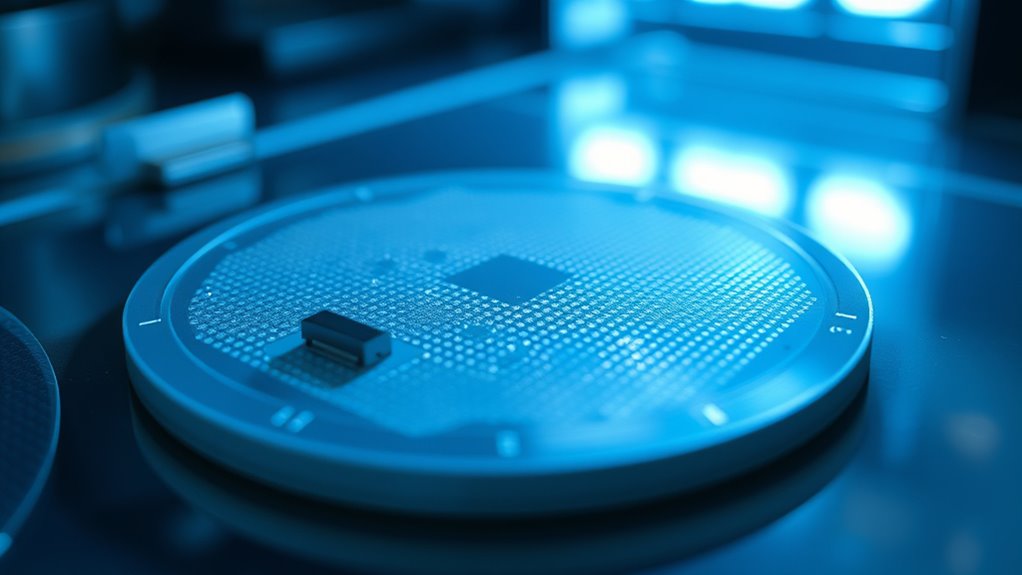

Have you ever wondered how microelectronics maintain their performance and reliability? It all comes down to meticulous cleaning processes that eliminate contaminants at the microscopic level. One of the most critical aspects of this is nanoparticle removal. Tiny particles, often invisible to the naked eye, can settle on surfaces during manufacturing or handling, causing defects or failures in delicate circuits. To guarantee high performance, you need cleaning methods capable of effectively removing these nanoparticles without damaging the underlying structures. This requires advanced techniques that target even the smallest contaminants, using specialized cleaning agents and processes designed for ultra-high purity environments.

Effective nanoparticle removal is key to ensuring microelectronics’ performance and reliability.

Another essential factor is surface wettability, which refers to how easily liquids can spread across a surface. In microelectronics cleaning, controlling surface wettability is crucial for ensuring thorough rinsing and drying. If a surface is overly hydrophobic, cleaning solutions may bead up and leave residues behind, compromising the integrity of the device. Conversely, if it’s too hydrophilic, it might attract unwanted contaminants or cause issues during subsequent processes. Achieving the right balance of surface wettability ensures that cleaning agents can uniformly contact every part of the surface, removing contaminants like oils, residues, and particles without leaving streaks or spots. Proper surface wettability also facilitates better drying, reducing the risk of water spots or ionic contamination that could affect the device’s performance.

Effective nanoparticle removal combined with optimized surface wettability translates into cleaner, more reliable microelectronic components. You need to pay close attention to the cleaning environment, selecting the right solvents and techniques that minimize surface tension and promote thorough cleaning. Techniques such as plasma cleaning, ultrasonication, and the use of surfactants are often employed to enhance nanoparticle removal and modify surface wettability to suit specific materials and device requirements. These methods work together to ensure that each component emerges from the cleaning process with no residues or particles left behind, maintaining the device’s integrity and longevity.

Additionally, understanding the surface chemistry of materials can help tailor cleaning protocols for optimal results. These methods work together to ensure that each component emerges from the cleaning process with no residues or particles left behind, maintaining the device’s integrity and longevity. When done correctly, these steps greatly reduce the risk of defects, improve yields, and extend the lifespan of microelectronic devices. Ultimately, the goal is to create a pristine surface that supports the complex functions of microelectronics, ensuring they perform flawlessly in their applications.

Frequently Asked Questions

What Are the Latest Innovations in Ultra-High Purity Cleaning Technologies?

You should explore the latest innovations like advanced nanoparticle removal techniques and surface modification methods. These technologies utilize ultra-high purity cleaning solutions to effectively eliminate tiny particles and alter surface properties, ensuring cleaner microelectronic components. By adopting these innovations, you can enhance device performance and reliability, reduce contamination risks, and meet stringent industry standards. Staying updated on these cutting-edge solutions helps you maintain competitive advantages in the rapidly evolving microelectronics landscape.

How Does Cleaning Impact the Lifespan of Microelectronic Components?

Did you know that proper cleaning can extend microelectronic component lifespan by up to 50%? When you focus on effective contamination removal and corrosion prevention, you reduce failure risks and improve reliability. Clean components resist corrosion better and maintain peak performance longer. So, your meticulous cleaning process directly impacts device durability, ensuring your microelectronics last longer and function flawlessly, saving you money and minimizing downtime.

What Are the Environmental Considerations of Ultra-Pure Cleaning Processes?

You need to ensure environmental regulations and waste management when implementing ultra-pure cleaning processes. These methods often use chemicals and generate waste that must be handled responsibly to prevent pollution. By following strict regulations, you reduce environmental impact and ensure safe disposal. Investing in eco-friendly cleaning solutions and proper waste management practices helps protect the environment while maintaining high purity standards in your microelectronics manufacturing.

How Do Industry Standards Influence Cleaning Protocols for Microelectronics?

Industry standards heavily influence your cleaning protocols by requiring strict regulatory compliance and contamination control measures. You must follow these guidelines to guarantee your processes meet safety, purity, and quality benchmarks. Adhering to standards like SEMI or IEC helps you minimize risks, avoid costly rework, and maintain product integrity. Compliance also demonstrates your commitment to quality, enabling you to stay competitive in the rapidly evolving microelectronics sector.

What Are Cost-Effective Strategies for Implementing High-Purity Cleaning?

Think of high-purity cleaning as fine tuning a delicate instrument—you want it pristine without breaking the bank. You can do this with affordable solutions like using optimized cleaning agents and recycling rinse water, making the process budget-friendly. Implementing routine maintenance and staff training also boosts efficiency, reducing waste and costs. These smart, budget-friendly methods guarantee you achieve ultra-high purity without draining your resources, keeping your microelectronics production both clean and cost-effective.

Conclusion

In the ever-evolving world of microelectronics, maintaining ultra-high purity is your secret weapon—like a knight’s shining armor in a modern-day labyrinth. By leveraging advanced cleaning techniques, you guarantee flawless device performance and longevity, avoiding the pitfalls of contamination. Remember, just as a skilled blacksmith refines steel, your meticulous cleaning practices forge the future of microelectronics, keeping it as pristine as a freshly polished gemstone in a vault of treasures. Stay ahead, and keep purity your top priority.