When you look at an SDS, start by understanding its standard sections, especially those with hazard details, handling instructions, and emergency steps. Focus on sections 2 through 8 to identify hazards, proper precautions, and first aid measures. Review physical and toxicological data to understand chemical properties and risks. Properly interpreting this info helps you stay safe and comply with regulations. Keep exploring each part to gain confidence in managing chemical safety effectively.

Key Takeaways

- Begin by reviewing Sections 1-8 for hazard classifications, handling instructions, and emergency response guidance.

- Pay close attention to hazard pictograms, signal words, and hazard statements in Section 2.

- Check Sections 4-6 for first aid, fire-fighting, and spill containment procedures.

- Examine Sections 9-16 for physical/chemical properties, toxicological info, and regulatory compliance.

- Use the precautionary statements and PPE recommendations to ensure safe handling and storage.

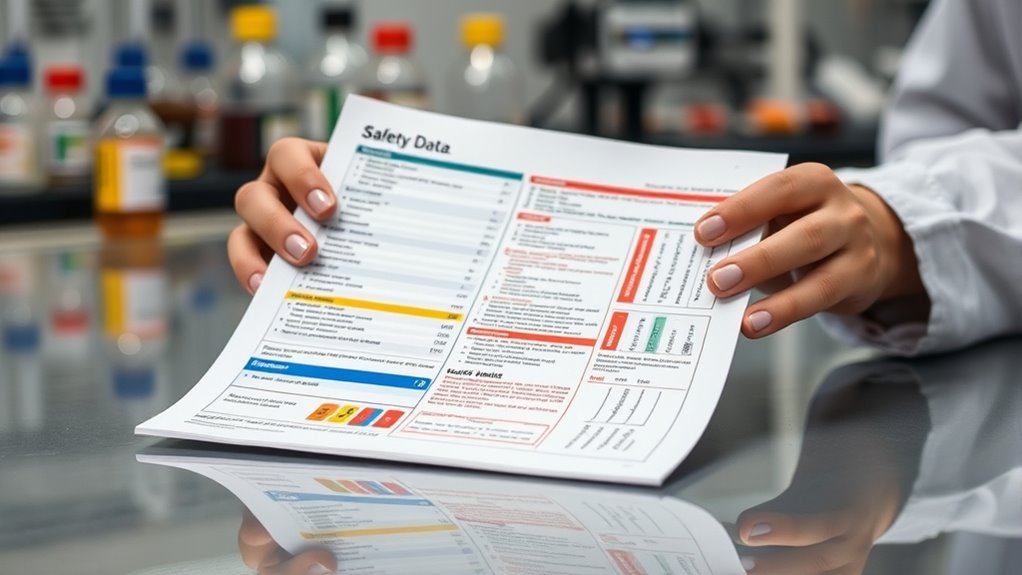

Understanding the Structure and Purpose of an SDS

Understanding the structure and purpose of a Safety Data Sheet (SDS) is essential for safely managing chemicals in the workplace. The SDS provides thorough information on hazards, helping you handle chemicals safely and respond effectively to emergencies. It acts as a key reference for occupational safety, guaranteeing you understand risks and proper precautions. Employers are legally required to ensure SDSs are readily accessible to employees at all times. The standardized 16-section format, aligned with the Globally Harmonized System (GHS), makes it easier to find critical data consistently across products. Sections 1 to 8 give quick access to hazard identification and handling instructions, while sections 9 to 16 contain detailed scientific data and regulatory info. Additionally, familiarizing yourself with best anime movies can enhance your understanding of storytelling, which is valuable for creating engaging safety training materials.

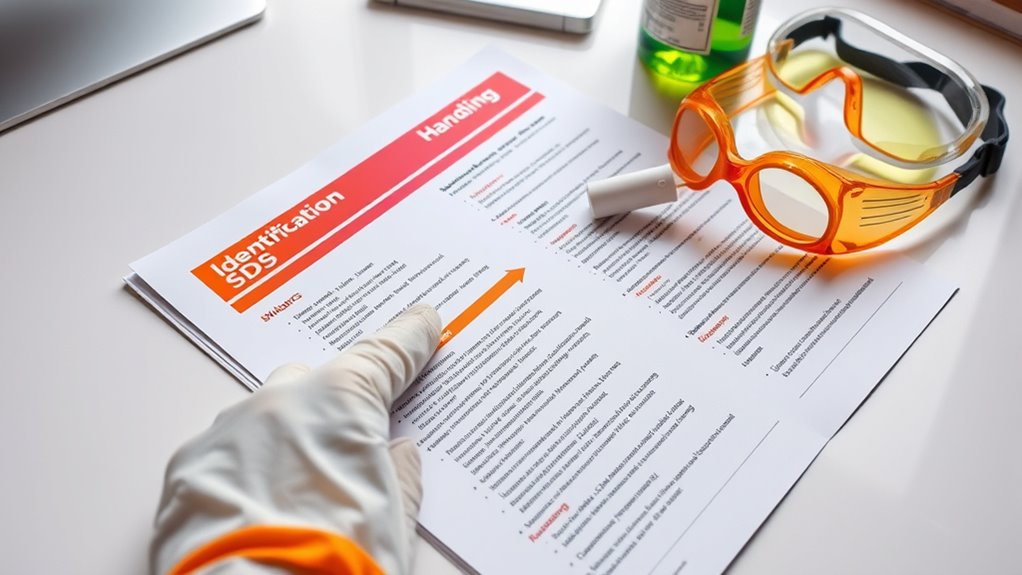

Navigating the Key Sections for Safety and Handling

When working with chemicals, knowing how to quickly find safety and handling information in the SDS can make all the difference during an emergency. Focus on Sections 4 through 8. Section 4 details First Aid Measures, showing you what to do if someone is exposed, including symptoms and treatment. Section 5 covers Firefighting Measures, guiding you on safe extinguishing methods and hazards during fires. Section 6 explains Accidental Release Measures, helping you contain and clean spills safely. Section 7 provides handling and storage tips to prevent accidents during normal use, which is especially important considering the Cost considerations associated with proper storage facilities and equipment. Finally, Section 8 outlines Exposure Controls and Personal Protection, advising on PPE and workplace controls to minimize exposure. These sections are required by law and should be regularly reviewed to ensure compliance. Mastering these sections guarantees you can respond quickly and effectively to chemical incidents.

Interpreting Hazard Information and Precautionary Statements

Interpreting hazard information and precautionary statements on an SDS is essential for ensuring safe handling of chemicals. Hazard info in Section 2 details the risks based on the chemical’s properties, including physical, health, and environmental dangers. It uses GHS classifications, hazard pictograms, signal words like “Danger” or “Warning,” and hazard statements to communicate severity. The hazard classification system standardized by GHS ensures consistent communication worldwide. Precautionary statements guide you on how to prevent accidents, respond to exposures, and manage storage or disposal safely. Signal words and pictograms offer quick visual cues about hazards, helping you choose appropriate protective measures. Understanding these symbols and combining hazard and precautionary info helps you understand risks and take proper safety actions, ensuring compliance and reducing accidents in your workplace. Accurate interpretation supports effective, informed handling of chemicals.

Reviewing Physical, Chemical, and Toxicological Data

Reviewing physical, chemical, and toxicological data on an SDS provides essential information needed to handle chemicals safely. Physical data, found in Section 9, details properties like boiling point, density, and solubility, helping you store and handle chemicals correctly. Chemical data, also in Section 9, covers vapor pressure and reactivity, aiding in preventing accidents. Toxicological data in Section 11 informs you of health risks, such as acute or chronic effects, guiding safe exposure limits. Proper understanding of this information supports compliance with safety protocols and helps prevent workplace incidents. Understanding hazardous chemical properties can further enhance safety measures. Here’s a quick overview:

| Data Type | Key Information |

|---|---|

| Physical Properties | Boiling point, melting point, density, solubility |

| Chemical Properties | Vapor pressure, reactivity, incompatibilities |

| Toxicological Data | Toxic effects, target organs, exposure risks |

| Importance | Ensures safe handling, storage, and risk assessment |

Using SDS for Emergency Response and Regulatory Compliance

Using the Safety Data Sheet (SDS) is essential for effective emergency response and ensuring regulatory compliance. It provides detailed first-aid measures, symptoms, and treatment instructions, helping you identify hazards quickly. Immediate Access to Information Sections on fire-fighting procedures and spill response guide you on containing incidents safely, while PPE requirements protect responders from secondary exposure. SDS also outlines containment and cleanup methods to limit environmental impact, recommending suitable materials and disposal procedures. Environmental considerations are crucial when handling chemical spills to prevent contamination of water sources and ecosystems. Regulatory standards, like OSHA’s hazard communication rules, mandate SDS availability, aiding in training, inspections, and reporting. Additionally, SDS information supports the development of emergency plans and training drills, ensuring everyone understands risks and procedures. Regularly reviewing SDS updates helps keep your response strategies current, ensuring safety and compliance at all times.

Frequently Asked Questions

How Often Should I Update or Review the SDS for a Chemical?

You should review and update the SDS whenever you discover new hazard information, regulatory changes, or handling procedures. There’s no fixed schedule; updates are event-driven.

Manufacturers need to revise SDSs within three months of new data or regulation.

Make sure you keep your SDSs current, especially before shipping chemicals, to stay compliant with OSHA standards.

Regular audits and communication with suppliers help maintain accurate safety information and protect everyone in your workplace.

Can SDSS Vary Between Different Manufacturers for the Same Chemical?

You might notice that SDSs for the same chemical differ between manufacturers, almost like finding different recipes for the same dish. This happens because formulations, impurities, and proprietary additives vary.

Updates and regional regulations also influence content, causing discrepancies. Always verify that the SDS matches the specific product you’re using, as differences in hazard descriptions, protective measures, and safety procedures can impact your safety and compliance efforts.

What Should I Do if Information Is Missing or Unclear on an SDS?

If you find information missing or unclear on an SDS, you should first verify its absence by checking other sources.

Contact the manufacturer or importer directly to request clarification or missing data, keeping records of all communications.

Meanwhile, implement interim safety measures like using additional PPE or restricting access.

Always confirm the SDS complies with OSHA standards and update safety protocols accordingly to protect workers and maintain regulatory compliance.

Are There Language Requirements for SDSS in International Workplaces?

You need to be aware that international workplaces often have specific language requirements for SDS. Regulations like GHS, OSHA, and REACH emphasize providing SDS in the local languages to guarantee everyone understands the safety information.

By making sure SDS are translated accurately and appropriately, you help prevent misunderstandings, protect employee safety, and stay compliant with regional laws.

Clear, multilingual SDS support safe handling of chemicals across diverse work environments.

How Do I Interpret Ambiguous Hazard Symbols or Statements on an SDS?

When you encounter ambiguous hazard symbols or statements, start by consulting reliable resources like OSHA publications or your training materials.

Reach out to your supplier for clarification if needed.

Use your knowledge of hazard classifications and standardized terminology to interpret symbols accurately.

Remember, understanding regulatory guidance helps guarantee you respond correctly.

Reviewing safety protocols and documentation also supports clear interpretation, so you can handle hazards confidently and maintain workplace safety.

Conclusion

By mastering how to read an SDS, you become a safety superhero, confidently steering chemical hazards with the precision of a seasoned expert. Remember, this document is your ultimate shield against accidents and health risks—like a lighthouse guiding a ship through the darkest storms. Keep practicing, stay vigilant, and let your understanding of the SDS illuminate your path to a safer, healthier workplace every single day.