High-barrier packaging helps protect your products from moisture and oxygen, extending shelf life. Materials like EVOH excel at blocking oxygen but can be affected by humidity, while PVDC offers strong moisture resistance and longevity. Alternatives such as biodegradable polymers aim to balance performance with sustainability. Understanding these options allows you to make smarter choices for effective, eco-friendly packaging. Keep exploring to discover how these materials can best suit your needs.

Key Takeaways

- EVOH provides excellent oxygen barriers but is sensitive to humidity, often combined with other materials for optimal performance.

- PVDC offers superior moisture and oxygen resistance but faces environmental concerns and higher costs.

- Emerging sustainable alternatives include bio-based and biodegradable polymers designed to match traditional high-barrier performance.

- Combining materials like EVOH or PVDC with eco-friendly layers can balance barrier properties and environmental impact.

- Advances in packaging technology aim to improve durability, extend shelf life, and reduce reliance on traditional plastics.

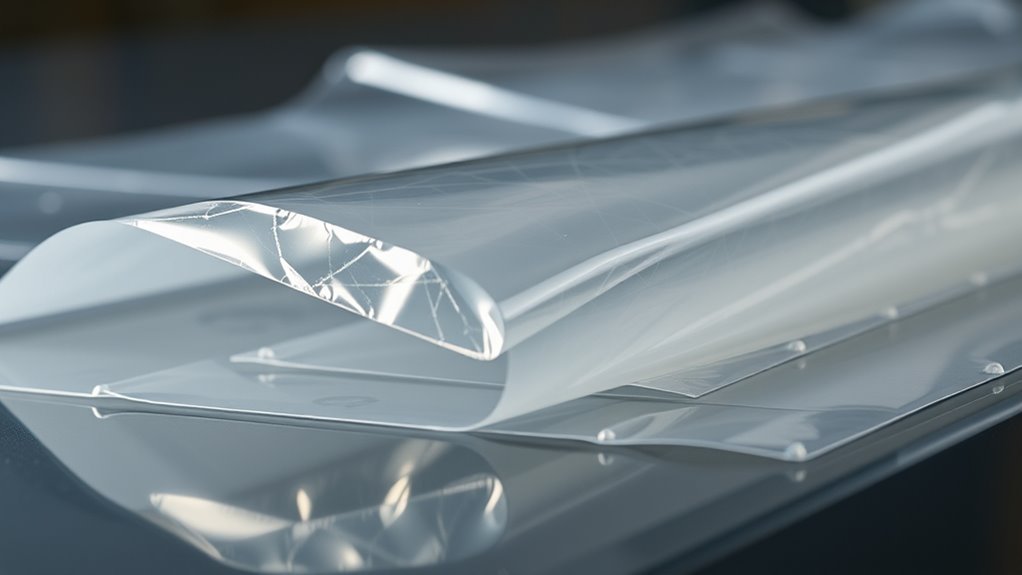

Have you ever wondered how certain products stay fresh for longer periods? It all comes down to the packaging that protects them from the elements. High-barrier packaging is designed specifically to extend shelf life by blocking out moisture and oxygen, which are the main culprits behind spoilage. When you choose products in high-barrier packaging, you’re essentially selecting containers that provide superior moisture resistance and a strong oxygen barrier. These features help prevent mold growth, bacterial contamination, and oxidation, ensuring the product remains fresh and safe longer.

Materials like EVOH (ethylene vinyl alcohol) and PVDC (polyvinylidene chloride) are at the forefront of high-barrier packaging. EVOH is especially prized for its excellent oxygen barrier properties. It actively reduces oxygen transmission, which is critical for preserving perishable foods like meats, cheeses, and snacks. Its moisture resistance is also remarkable, though it can be influenced by environmental humidity; in high humidity conditions, EVOH may need to be combined with other materials to maintain its effectiveness. PVDC, on the other hand, has remarkable moisture resistance and an outstanding oxygen barrier, making it suitable for products that require extended protection from both moisture and oxygen ingress. You’ll often find PVDC used in film laminates and wrappers where longevity is essential.

But what if you’re looking for alternatives? Researchers and manufacturers are increasingly exploring new materials and composites that deliver high barrier performance without some of the drawbacks associated with EVOH and PVDC, such as environmental concerns or cost. For example, some bio-based or biodegradable polymers are being engineered to provide comparable moisture resistance and oxygen barriers. These alternatives aim to reduce reliance on traditional plastics while still maintaining the protective qualities you need for freshness. They’re particularly appealing if sustainability is a priority for you or your business.

Additionally, innovations in packaging technology are continually improving the effectiveness and environmental footprint of high-barrier materials. Ultimately, the goal of high-barrier packaging is to keep your products in ideal condition for as long as possible. By choosing packaging materials with excellent moisture resistance and a reliable oxygen barrier, you’re protecting the product from spoilage and extending its shelf life. Whether it’s EVOH, PVDC, or innovative new alternatives, these materials work together to create a robust defense against the elements that threaten product quality. As a consumer or manufacturer, understanding these materials helps you make smarter choices, ensuring freshness, safety, and reduced waste.

Frequently Asked Questions

How Do EVOH and PVDC Compare Environmentally?

You’ll find that EVOH and PVDC differ in their environmental impact and recyclability challenges. EVOH is generally more eco-friendly because it’s easier to recycle and has a lower carbon footprint. PVDC, however, poses significant recyclability challenges due to its complex structure, making it harder to process and dispose of responsibly. Choosing EVOH can help reduce environmental impact, but both materials require careful management to minimize waste and pollution.

What Are the Latest Innovations in High-Barrier Packaging?

You should explore the latest innovations in high-barrier packaging, which include innovative coatings that enhance barrier properties while reducing environmental impact. Manufacturers are now using sustainable materials, such as bio-based polymers and biodegradable films, to replace traditional EVOH and PVDC. These advancements aim to improve product shelf life and environmental sustainability, allowing you to meet consumer demand for eco-friendly packaging options while maintaining high-performance protection.

Are There Cost-Effective Alternatives to EVOH and PVDC?

You’ll find that some alternatives are like hidden gems, offering cost reduction without sacrificing material durability. For example, polyamide and certain bioplastics provide decent barrier properties at a lower price point. These options help you cut costs while maintaining quality, making your packaging more sustainable and budget-friendly. While they may not match EVOH or PVDC perfectly, they’re promising choices that balance performance with affordability.

How Do Barrier Properties Affect Food Shelf Life?

Barrier properties directly impact your food’s shelf life by controlling moisture resistance and oxygen permeability. If packaging effectively resists moisture, it prevents spoilage caused by humidity. Low oxygen permeability slows microbial growth and oxidation, preserving freshness longer. When barrier properties are optimized, your food stays fresher, tastefully intact, and safe for extended periods, reducing waste and ensuring quality from packaging to consumption.

What Regulatory Challenges Exist for New Barrier Materials?

You’ll face regulatory challenges like obtaining approval for new barrier materials, ensuring they meet safety standards, and steering complex approval processes. Labeling requirements also come into play, as you must clearly communicate material contents and their safe use on packaging. Staying compliant means staying updated on evolving regulations, conducting thorough testing, and working closely with authorities to secure regulatory approval, so your packaging remains legal and trustworthy.

Conclusion

When choosing high-barrier packaging, you open a world of protection—EVOH, PVDC, or alternatives—each with its unique strengths. Think of it as a dance where materials move in perfect harmony, safeguarding your products while respecting sustainability. By understanding these options, you’re not just wrapping goods; you’re crafting a shield that preserves freshness and quality. Embrace the rhythm of innovation, and let your packaging tell a story of resilience and responsibility.