Antimicrobial surfaces now harness silver nanoparticles, which kill microbes by damaging membranes, releasing ions that disrupt enzymes, and preventing biofilms. These surfaces also use principles like superhydrophobicity and nanostructures to repel microbes naturally. Beyond bacteria, they target viruses and fungi, making them versatile. Innovative coatings and materials are continually evolving to boost durability and safety. To discover how these technologies work and what future developments are ahead, keep exploring these exciting advances.

Key Takeaways

- Silver nanoparticles exert antimicrobial effects through membrane penetration, silver ion release, ROS generation, enzyme inhibition, and biofilm disruption.

- Surface properties like superhydrophobicity, hierarchical structures, and chemical modifications enhance antimicrobial surface effectiveness.

- Antimicrobial surfaces incorporate silver nanoparticles, gold ions, or nanostructures to target bacteria, fungi, and viruses across various applications.

- Innovations include nanocoatings with active ingredients that maintain durability and efficacy on diverse substrates like metals and plastics.

- Future challenges involve ensuring biocompatibility, environmental safety, and overcoming regulatory hurdles while exploring advanced material integrations.

Understanding the Antimicrobial Power of Silver Nanoparticles

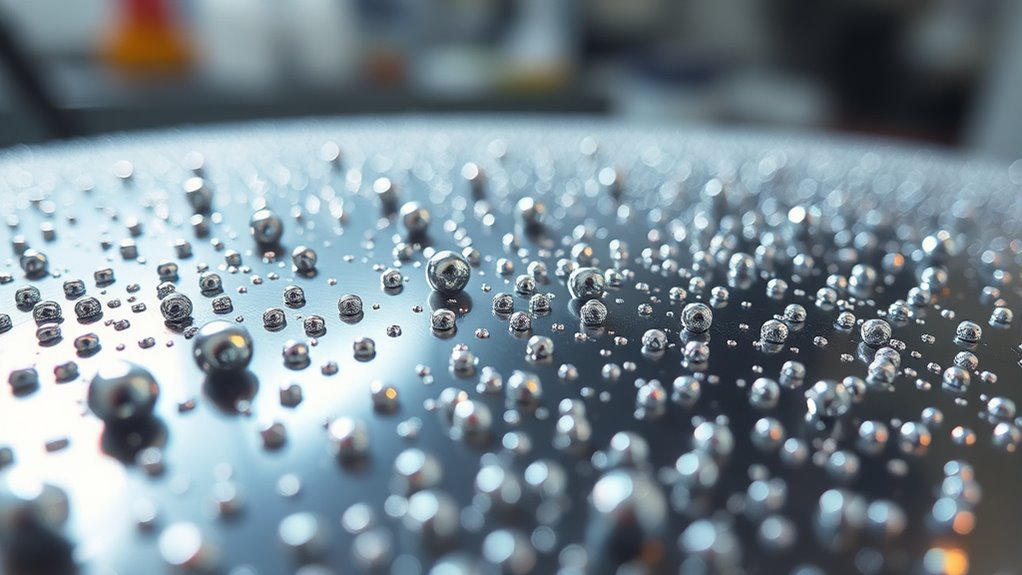

Silver nanoparticles (AgNPs) are powerful antimicrobial agents whose effectiveness stems from multiple mechanisms. First, their tiny size (10–100 nm) allows them to adhere to and penetrate microbial cell membranes, disrupting their integrity. They also release silver ions that cause oxidative stress, damage DNA, and inhibit essential enzymes, weakening the microbes further. The materials used in AgNPs can be tailored to enhance their stability and efficacy in various applications. Additionally, AgNPs generate reactive oxygen species (ROS), which attack cellular components and interfere with metabolic processes. They can work synergistically with antibiotics, boosting their killing power, and inhibit biofilm formation by disrupting microbial communication and adhesion. Moreover, the manufacturing processes of AgNPs influence their surface properties and antimicrobial activity. These combined actions make AgNPs effective against a broad spectrum of pathogens, including bacteria, fungi, and viruses, making them invaluable in creating antimicrobial surfaces and applications. The spiritual energy of these particles can influence their interactions with microbes, enhancing their effectiveness in some cases.

Key Properties That Enhance Effectiveness

The effectiveness of antimicrobial surfaces depends heavily on their physical and chemical properties, which can be engineered to repel or kill microbes more efficiently. Surface wettability plays a pivotal role; superhydrophobic surfaces with water contact angles above 150° create air nanobubbles that reduce microbial contact and attachment. Additionally, incorporating automation technologies can facilitate more consistent manufacturing processes, ensuring uniform surface properties and enhancing overall antimicrobial performance. Hierarchical micro-nanostructures act as physical barriers, further preventing microbial adhesion. Chemical modifications with low surface energy materials boost repellence and durability. However, wear, immersion, or environmental factors can diminish these air layers, reducing effectiveness over time. Durability is essential; surfaces must resist mechanical damage and environmental exposure to sustain antimicrobial activity. Combining physical topographies with chemical agents like silver ions enhances overall performance, ensuring surfaces remain effective longer in real-world conditions. Moreover, the use of nanoparticle coatings allows for targeted antimicrobial action, leveraging unique properties of nanomaterials to improve longevity and effectiveness. Proper surface design must also consider material stability, ensuring long-term resistance against environmental degradation and maintaining antimicrobial properties throughout usage.

Expanding antimicrobial surfaces to include antiviral and antifungal properties involves leveraging the unique abilities of silver nanoparticles (AgNPs). You’ll find that AgNPs effectively disrupt viral replication by targeting viral components, reducing viral loads, and preventing infections from spreading. This makes them suitable for coatings on medical devices, especially to curb viral transmission and combat respiratory viruses. Additionally, advancements in nanotechnology have led to the development of high-performance coatings that enhance the durability and efficacy of these antimicrobial surfaces. The mechanism of action of AgNPs involves multiple pathways that make them highly effective against a broad spectrum of pathogens. On the antifungal side, AgNPs target fungi like Candida and Trichophyton by damaging cell membranes and disrupting metabolism. They’re often incorporated into wound dressings to prevent fungal infections and promote healing. Higher concentrations boost effectiveness, and fungi are less likely to develop resistance to silver than to traditional drugs. These properties expand AgNPs’ applications beyond bacteria, offering versatile solutions for antiviral and antifungal needs across healthcare and other industries, including indoor plant care where antimicrobial surfaces can help maintain healthier environments.

Innovations in Surface Coatings and Material Integration

Recent advancements in surface coating technologies leverage innovative materials and nanotechnology to enhance antimicrobial effectiveness. You can now benefit from coatings that incorporate active ingredients like silver, gold ions, titanium, or organosilane, which actively kill microorganisms on contact.

Nanotechnology plays a pivotal role by enabling nano-scale agents that maximize microbial contact and disruption, leading to more durable and potent protections. Innovations also focus on maintaining antimicrobial activity even after cleaning and disinfection, targeting resilient pathogens like MRSA and VRE.

Polymer-based coatings help preserve surface appearance and functionality while embedding antimicrobial properties. These coatings are adaptable for various substrates, including metals, plastics, and glass, expanding their application across industries such as healthcare, food processing, and consumer appliances.

This integration enhances surface hygiene without compromising aesthetics or performance, and maintaining long-term efficacy remains a key focus in ongoing research.

Navigating Future Challenges and Opportunities

While innovative antimicrobial surfaces offer promising solutions for hygiene, they also present significant development challenges. You must address biocompatibility to guarantee these surfaces are safe for humans and the environment, which isn’t easy. Costly development and complex regulatory processes can slow adoption.

Innovative antimicrobial surfaces face challenges like biocompatibility, high development costs, and complex regulations.

Overuse of these surfaces risks creating resistant microbes, undermining their effectiveness. Environmental concerns, especially with nanoparticles like silver, pose risks to aquatic ecosystems. Biofilm formation complicates surface design, as these structures are resistant and persistent.

Future opportunities include integrating these surfaces into advanced tech, improving healthcare safety, and extending food shelf life. Emerging materials inspired by nature, antimicrobial polymers, and hybrid structures open new possibilities.

Navigating these challenges wisely will be key to opening their full potential while safeguarding health and the environment.

Frequently Asked Questions

How Do Silver Nanoparticles Compare With Other Antimicrobial Nanomaterials?

When comparing silver nanoparticles to other antimicrobial nanomaterials, you’ll find that AgNPs have a broad spectrum of activity. They penetrate bacterial cells and disrupt their membranes effectively.

They outperform materials like gold or titanium dioxide in antimicrobial versatility. While zinc oxide and copper also work, AgNPs often show stronger and quicker antimicrobial effects.

Their ability to inhibit biofilms and enhance antibiotics makes them particularly promising for medical and environmental applications.

Are There Environmental Concerns Associated With Silver Nanoparticle Disposal?

You should be aware that disposing of silver nanoparticles raises environmental concerns. They often end up in wastewater, where they can transform, aggregate, and attach to organic matter, making them mobile and bioavailable.

These particles can harm microorganisms crucial for ecosystems and wastewater treatment. Persistent in the environment, they may bioaccumulate in organisms, disrupting food chains.

Proper waste management and further research are essential to minimize their ecological impact.

What Are the Regulatory Standards for Using Agnps in Medical Devices?

Imagine a world where tiny silver particles wield immense power over health and safety. You need to recognize that regulatory standards for AgNPs in medical devices are strict and precise.

In the U.S., the FDA enforces rigorous safety and efficacy rules, while the EU requires conformity assessments by Notified Bodies.

You must guarantee proper particle characterization, biocompatibility testing, and adherence to international standards to meet these high-stakes regulations.

Can Silver Nanoparticle Coatings Cause Allergic Reactions or Sensitivities?

You might wonder if silver nanoparticle coatings can cause allergic reactions or sensitivities. Evidence suggests they can, especially through inhalation or skin contact.

Silver nanoparticles can trigger immune responses, increase IgE levels, and promote inflammation, which may worsen allergies or cause new sensitivities. Smaller particles penetrate tissues more easily, heightening this risk.

While animal studies support this, human data is limited, so caution and monitoring are essential when using AgNPs in products.

How Cost-Effective Are Large-Scale Productions of Agnp-Based Antimicrobial Surfaces?

You might think large-scale AgNP production is prohibitively expensive, but with advancements in manufacturing, it’s becoming surprisingly cost-effective. Techniques like thermal embedding and continuous processes drastically cut costs, especially when using mass-produced polymers and minimal silver layers.

Although still pricier than traditional methods, optimized biosynthesis and surface engineering are making these antimicrobial surfaces more accessible, potentially transforming industries without breaking the bank.

Conclusion

You now know that silver nanoparticles can reduce bacteria by up to 99.9%, making surfaces markedly safer. But the future holds even more promise with new materials fighting viruses and fungi. By exploring innovative coatings, you’re helping to create cleaner, healthier environments. As antimicrobial surfaces become more advanced, they could save countless lives—so stay curious and keep an eye on this exciting field. The potential for improved public health is truly remarkable.