Conductive polymers play a key role in wearables by enabling flexible, lightweight, and biocompatible electronic components. They let you embed sensors, circuits, and conductive pathways directly into fabrics, making devices more comfortable and durable. These materials can stretch and bend with your movements, ensuring consistent performance. As they continue to evolve, they’ll unleash even smarter and more integrated wearable solutions—stay tuned to discover how these advanced materials are shaping the future of technology.

Key Takeaways

- Conductive polymers enable flexible, lightweight electronic components integrated directly into textiles for wearable applications.

- They provide durable, stretchable conductive pathways that maintain performance during movement and deformation.

- These polymers are engineered for biocompatibility, making them suitable for skin-contact sensors and health monitoring devices.

- They can be processed via printing, coating, or fiber spinning, facilitating scalable manufacturing of smart textiles.

- Ongoing research aims to enhance conductivity, durability, and cost-effectiveness for broader adoption in wearables.

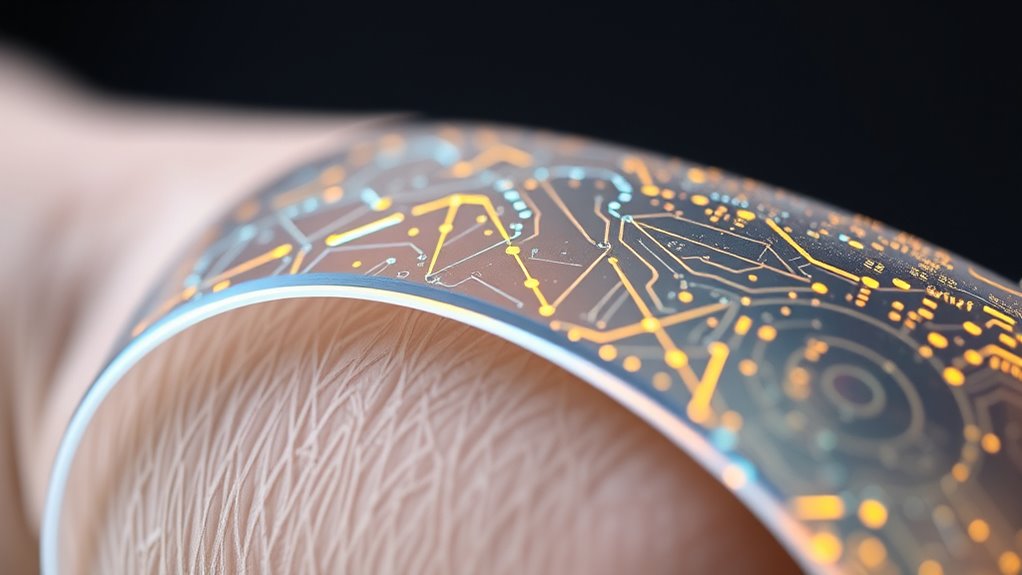

Conductive polymers are revolutionizing wearable technology by enabling flexible, lightweight, and efficient electronic components. As you explore this innovative field, you’ll find that these materials are essential in creating smart textiles that seamlessly blend functionality with comfort. Smart textile integration allows you to embed sensors, circuits, and conductive pathways directly into fabrics, making wearables less bulky and more adaptable to daily life. These textiles respond to stimuli such as temperature, pressure, or moisture, providing real-time data for health monitoring, sports performance, or environmental awareness. Because conductive polymers are inherently flexible, they can bend and stretch with the fabric, maintaining electrical performance even during movement. This flexibility is critical for wearables that need to conform to your body without sacrificing durability or comfort.

In addition to their mechanical advantages, conductive polymers are at the forefront of biocompatible material development. When designing wearables intended for prolonged skin contact or medical applications, biocompatibility becomes a top priority. These materials are often engineered to be non-toxic, hypoallergenic, and compatible with human tissue, reducing the risk of irritation or adverse reactions. This focus on biocompatibility enhances the usability of health monitoring devices, wearable sensors, and implantable electronics, making them safer and more comfortable for everyday use. The development process involves selecting or modifying polymers to improve their interaction with biological systems while maintaining electrical conductivity. By integrating biocompatible conductive polymers into wearable devices, you can guarantee that they not only perform well but also safely coexist with your body over extended periods. Additionally, ongoing research into cost-effective production methods aims to make these advanced materials more accessible for widespread adoption in wearable technology.

Furthermore, the versatility of conductive polymers extends to their ability to be processed using various manufacturing techniques, such as printing, coating, or spinning into fibers. This adaptability makes it easier for you to incorporate them into different textile structures or create custom wearable solutions tailored to specific needs. They can be integrated into existing manufacturing workflows, reducing costs and streamlining product development. As research advances, you’ll see new formulations that combine high conductivity with enhanced biocompatibility and mechanical resilience, broadening the scope of wearable applications. Whether for sports, healthcare, or fashion, conductive polymers are paving the way for smarter, more comfortable, and more durable wearables that keep pace with your lifestyle.

Frequently Asked Questions

How Do Conductive Polymers Compare to Metals in Wearables?

You’ll find conductive polymers are more cost-efficient and easier to manufacture than metals for wearables. They’re lightweight, flexible, and can be integrated into complex designs without much hassle. Unlike metals, they don’t require expensive processing or high temperatures, reducing production complexity. This makes conductive polymers a practical choice, allowing you to create comfortable, innovative wearables without sacrificing performance or affordability.

Are Conductive Polymers Environmentally Sustainable?

Yes, conductive polymers are generally more environmentally sustainable than metals because they have a lower ecological footprint and better biodegradability. You’ll find that they require less energy to produce and can decompose more easily, reducing waste and pollution. By choosing conductive polymers, you’re supporting eco-friendly options that help minimize environmental impact, making them a smarter choice for sustainable wearable technology.

Can Conductive Polymers Be Used in Flexible, Stretchable Devices?

Imagine a rubber band that bends and stretches without breaking—conductive polymers can do the same in flexible, stretchable devices. You’ll need to focus on biocompatibility testing to guarantee safety and consider manufacturing scalability for mass production. These polymers are versatile, adapting to your device’s shape while maintaining conductivity, making them perfect for wearable tech that moves with you. With proper testing and scalable methods, your devices can be both durable and comfortable.

What Are the Main Challenges in Commercializing Conductive Polymer Wearables?

You face challenges in commercializing conductive polymer wearables, mainly due to scaling up mass production and reducing costs. Achieving consistent quality during large-scale manufacturing can be difficult, and expensive materials or processes raise overall costs. To succeed, you need to develop efficient, cost-effective production methods that guarantee durability and performance. Overcoming these hurdles will make conductive polymer wearables more accessible and practical for widespread use.

How Do Conductive Polymers Impact the Device’s Lifespan and Durability?

You’ll find that conductive polymers influence your device’s lifespan and durability through polymer degradation and mechanical robustness. When polymer degradation occurs, conductivity weakens, reducing performance over time. Meanwhile, if the polymers lack mechanical robustness, they become more prone to cracking or breaking under stress. By maintaining a balance between stability and flexibility, you guarantee your wearable remains reliable, long-lasting, and capable of withstanding daily wear and tear.

Conclusion

So, as you explore conductive polymers in wearables, you’ll find they’re revolutionizing the way you interact with technology—almost like having your own personal Stark Industries upgrade. These materials make your devices more flexible, durable, and smarter, all while keeping you connected. With ongoing innovation, the future of wearables is bright, blending cutting-edge science with everyday life. It’s like stepping into a sci-fi novel, but this time, you’re the protagonist in a world powered by conductive polymers.