To trust your cleanroom data, it is vital to understand particle counters’ counting efficiency. These devices measure airborne particles, but their accuracy depends on proper calibration with traceable standards and regular adjustments. When calibration is maintained, counting efficiency improves, ensuring your measurements reflect true particle levels. This helps prevent false alarms or missed contamination. If you keep exploring, you’ll discover how to optimize your particle counting processes and guarantee reliable cleanroom monitoring.

Key Takeaways

- Counting efficiency determines how accurately a particle counter detects and counts particles of different sizes in the sampled air.

- Proper calibration ensures the particle counter’s counting efficiency aligns with known standards, maintaining measurement reliability.

- Variations in flow rate, particle size, and instrument design can affect counting efficiency, impacting data accuracy.

- Regular calibration with certified standards helps identify and correct counting inefficiencies, ensuring trustworthy cleanroom data.

- High counting efficiency is essential for detecting low-level contamination and meeting industry regulatory standards.

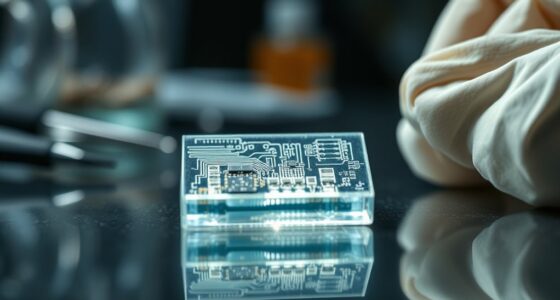

Have you ever wondered how industries guarantee the air and surfaces stay free of harmful particles? It all comes down to the precision and reliability of particle counters. These devices are essential tools that measure airborne particles, helping facilities maintain sterile environments, especially in cleanrooms and pharmaceutical manufacturing. To ensure accurate readings, it’s crucial that particle counters are properly calibrated. Calibration techniques involve comparing the device’s measurements with a known standard, ensuring that the readings reflect real particle concentrations. Regular calibration is vital because even slight deviations can lead to inaccurate data, which might compromise product safety or regulatory compliance. In practice, calibration techniques often include using reference aerosols or certified calibration standards, allowing you to fine-tune your particle counter to match known particle sizes and concentrations. This process helps you detect subtle changes in airborne particle levels, giving you confidence that your cleanroom environment remains within specified limits. Additionally, understanding airborne particle size is critical for selecting appropriate calibration methods that target the specific particles of concern in your environment.

Understanding how particle counters work and the importance of calibration techniques can significantly impact your ability to monitor air quality effectively. When you operate a particle counter, you’re essentially counting airborne particles that could pose contamination risks. The device’s sensors detect particles as small as a fraction of a micron, but these sensors require regular calibration to maintain their sensitivity and accuracy. Without proper calibration, your readings can drift, leading to either false alarms or overlooked contamination. This is why industry standards emphasize routine calibration, often involving procedures like using traceable reference standards or conducting pre- and post-measurement validations. These calibration techniques ensure your particle counter’s measurements are consistent over time, allowing you to make informed decisions about your environment’s cleanliness.

Frequently Asked Questions

How Often Should Particle Counters Be Calibrated?

You should calibrate particle counters at least every 6 to 12 months, depending on your maintenance schedules and usage. Regular calibration guarantees accurate readings and maintains reliable data for your cleanroom. If your environment experiences heavy use or critical processes, more frequent calibration might be necessary. Always follow the manufacturer’s recommendations and document calibration dates to stay compliant and ensure peak performance of your particle counting equipment.

What Are Common Sources of Particle Counter Inaccuracies?

Particle counter inaccuracies can sneak in like shadows, especially from environmental influences such as temperature and humidity fluctuations. These factors can throw off your readings if calibration frequency isn’t maintained properly. Dust, vibrations, and aging components also contribute to errors. To keep your data trustworthy, regularly check and calibrate your particle counters, ensuring environmental conditions are stable, so your measurements remain as precise as a hawk’s eye.

Can Particle Counters Detect All Types of Airborne Particles?

Particle counters can’t detect all airborne particles due to particle detection limitations. They are generally effective for specific particle size ranges, but smaller particles may evade detection because of their size resolution constraints. This means that some ultrafine or very tiny particles might not register, potentially leading to gaps in your air quality data. To guarantee thorough monitoring, understand your device’s particle detection limitations and choose counters with suitable particle size resolution for your cleanroom needs.

How Does Environmental Temperature Affect Particle Counter Readings?

Temperature fluctuations can impact your particle counter readings by affecting sensor sensitivity. When temperatures vary, sensors may become less precise, leading to inaccurate particle counts. You should monitor environmental temperature closely and make certain your device is calibrated for the specific conditions of your cleanroom. Consistent temperature control helps maintain measurement accuracy, so you get reliable data and maintain cleanroom standards effectively.

Are Portable Particle Counters as Reliable as Fixed Units?

Imagine two guardians watching over your cleanroom—one portable, one fixed. You’ll find that portable particle counters offer good reliability, but their accuracy can’t always match the stability of fixed units. Portable reliability makes them ideal for quick checks and hard-to-reach spots, while fixed units provide consistent, long-term data. You should choose based on your specific needs, knowing each has strengths and limitations for maintaining cleanroom integrity.

Conclusion

Now that you understand how particle counters work, you’re armed with a clear lens to see your cleanroom’s true story. Think of these devices as vigilant guardians, catching every tiny intruder with precision. When you trust their data, you’re steering a clear, starry sky instead of a foggy haze. With this knowledge, you’ll keep your environment pristine, like a master gardener tending to a delicate, flawless bloom. Your cleanroom’s success depends on it.