Thermal Gravimetric Analysis (TGA) helps you understand polymers by measuring weight changes during controlled heating, revealing their thermal stability, decomposition points, and composition. It detects volatile components, fillers, and residual moisture, providing insights into durability and degradation pathways. TGA is widely used for quality control, material development, and analyzing complex systems. To get detailed tips on optimizing your experiments and interpreting data, continue exploring the key techniques and considerations involved.

Key Takeaways

- TGA measures weight changes during controlled heating to determine polymer stability, composition, and degradation pathways.

- It identifies decomposition temperatures and residual char, providing insights into thermal stability and material durability.

- TGA quantifies volatile components, fillers, and moisture content, aiding in material characterization and quality control.

- Combining TGA with techniques like DSC, FTIR, or MS helps clarify complex degradation mechanisms and compositional details.

- Proper sample preparation, heating rate control, and use of purge gases improve accuracy and resolution in polymer analysis.

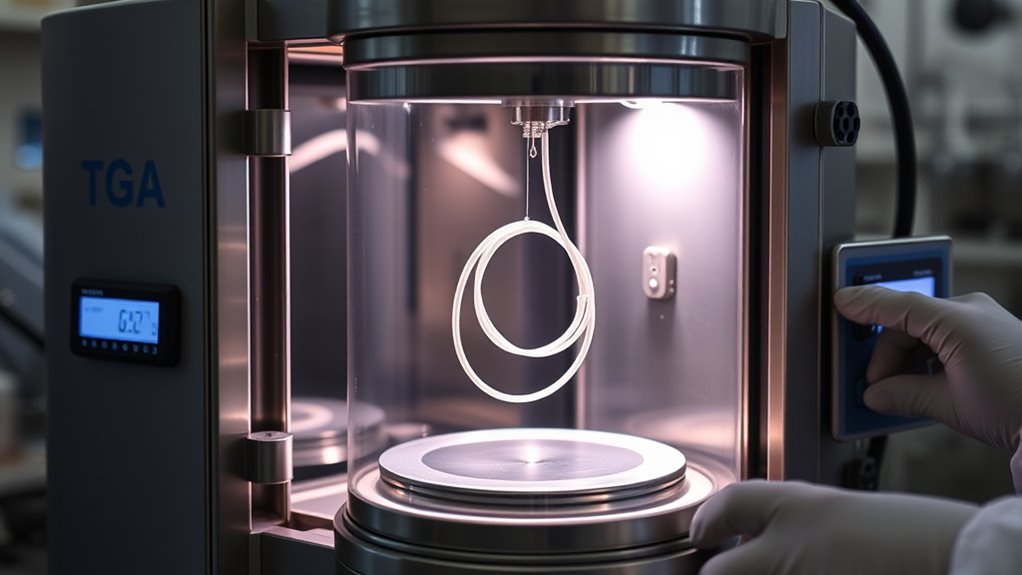

Principles and Fundamentals of TGA in Polymer Analysis

Have you ever wondered how TGA helps analyze polymers? TGA measures how much a sample’s weight changes as you heat it under a controlled atmosphere. It detects mass loss or gain from decomposition, oxidation, or volatile loss, like moisture.

TGA reveals polymer composition and stability through precise weight change measurements during heating.

The results appear as thermograms, which are graphs of weight versus temperature or time. This technique is often paired with differential scanning calorimetry (DSC) to give a detailed understanding of composition and stability.

During heating, polymers lose weight at specific temperature ranges, revealing moisture, additives, or degradation processes. By controlling the atmosphere—either inert like nitrogen or reactive like oxygen—you can study different behaviors. Additionally, the integration of automation in analysis helps improve throughput and data accuracy in polymer characterization.

TGA’s precise measurement of small mass changes helps you assess polymer stability, composition, and degradation characteristics effectively. Best anime movies can serve as a creative analogy for understanding complex data patterns in TGA analysis. Additionally, understanding the thermal decomposition process is crucial for developing more durable polymers.

Key Applications of TGA in Polymer Research and Industry

Thermal Gravimetric Analysis (TGA) plays a vital role in advancing polymer research by providing detailed insights into material stability and composition. You use TGA to assess how polymers degrade at specific temperatures, helping determine their thermal stability.

It enables you to analyze the composition by quantifying volatile components and fillers, such as glass fibers in composites. TGA also supports degradation control studies, revealing how small changes affect properties, and helps predict product lifetimes through decomposition kinetics.

In industry, TGA guarantees quality control, guides material selection, and evaluates coatings and adhesives for thermal endurance. It’s invaluable for recycling efforts, identifying reusable components, and testing polymers used in automotive and biomedical applications.

Interpreting TGA Data: What Does Mass Loss Tell Us?

Mass loss observed in TGA provides direct insights into a polymer’s thermal stability and degradation behavior. The temperature where mass loss begins indicates the decomposition point, revealing how resistant the polymer is to heat. Additionally, the presence of multiple degradation steps can suggest the coexistence of different components or phases within the material, aiding in detailed analysis. The rate of mass loss helps understand the kinetics and mechanisms behind degradation. Sharp drops suggest a single, well-defined breakdown, while multiple steps point to complex compositions or additives. Early mass loss, often below 150 °C, usually results from moisture or residual solvents, helping you assess moisture content and processing stability. Residual mass after heating indicates char formation or inorganic fillers. Furthermore, analyzing the thermal degradation patterns can be crucial for predicting the lifespan and performance of polymer products in real-world applications. Additionally, the shape and steps in the TGA curve help differentiate components in blends or composites, enabling you to analyze composition, filler content, and degradation patterns precisely. Pinball machines can also be studied using TGA to analyze materials used in their construction, providing insights into their durability and aging processes.

Advantages of Using TGA for Polymer Characterization

Using TGA to characterize polymers offers several clear advantages that streamline material selection and development. It helps you identify the components in multi-material systems, making it easier to choose polymers suited for specific applications.

TGA simplifies polymer identification, aiding precise selection for diverse applications.

TGA also reveals a polymer’s thermal stability, which is essential for predicting performance under high temperatures. It assesses oxidative stability, so you know how materials will degrade in different environments.

Measuring filler content allows you to optimize composite properties, while analyzing moisture and volatile content helps understand environmental effects on performance. Polymer tuning techniques can be complemented by TGA data to further refine material properties for specific uses.

Additionally, TGA enables quick screening of materials, reducing costs and speeding up research. Continuous training in TGA techniques keeps analysts updated on the latest advancements and best practices. Incorporating analytical methods like TGA enhances the accuracy and reliability of material assessments.

Its versatility applies across industries, from aerospace to food packaging, providing reliable, rapid insights that enhance material development and product quality.

Limitations and Considerations in TGA Experiments

When conducting TGA experiments on polymers, it’s important to recognize that the technique has inherent limitations that can affect your results. TGA measures mass loss, but this doesn’t always directly indicate the extent of polymer degradation, since some processes like volatilization may occur without significant mass change.

Volatile products often only form at high temperatures, which can mask early degradation stages. Oxygen diffusion into the sample can influence oxidative reactions, leading to inaccurate assessments of stability. Additionally, different polymers and components exhibit varying reaction kinetics, complicating data interpretation.

Proper sample preparation, consistent calibration, and controlled atmosphere conditions are essential for reliable results. Moreover, understanding the specific reaction mechanisms involved can help interpret complex TGA data more accurately. Employing complementary analytical techniques can also provide a more comprehensive understanding of thermal behavior. Ultimately, combining TGA with other techniques can help overcome some limitations and provide a fuller understanding of thermal behavior.

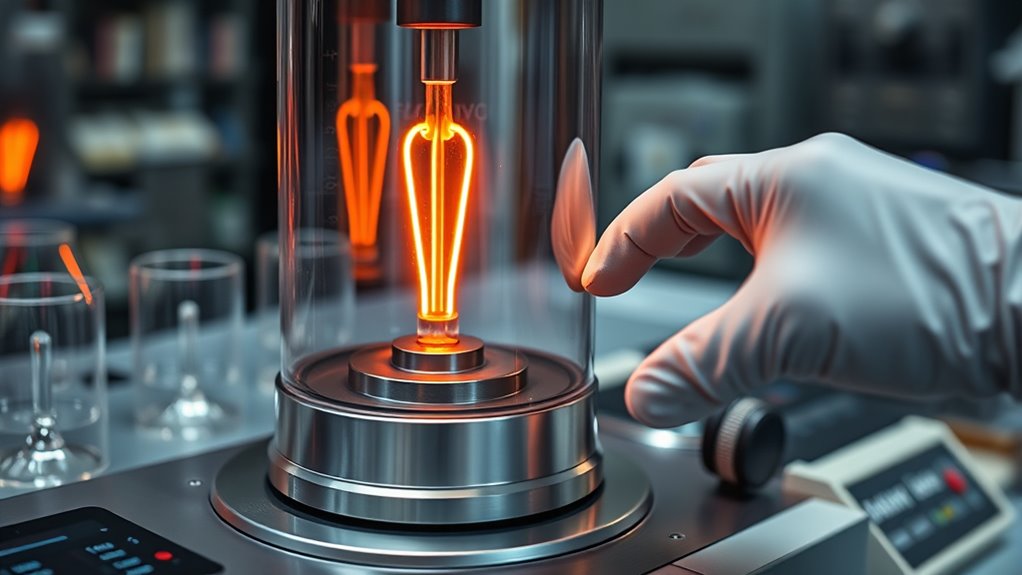

Critical Parameters Measured During TGA Analysis

Understanding the parameters measured during TGA analysis is essential for accurately interpreting a polymer’s thermal behavior. You’ll assess moisture content to determine sample purity and stability, while volatile content reveals the presence of solvents or other volatile substances.

Accurately interpreting TGA data reveals polymer stability, composition, and thermal behavior.

Ash content indicates inorganic residues remaining after combustion, and Loss on Ignition (LOI) quantifies mass loss due to heating. Thermal stability is evaluated by analyzing weight changes across temperature ranges, highlighting decomposition or phase transitions.

These measurements also help identify physical phenomena like melting points, sublimation, and adsorption-desorption processes. Additionally, chemical reactions such as decomposition, oxidation, and polymer degradation influence weight loss patterns.

Monitoring these parameters provides critical insights into material composition, stability, and durability, ensuring accurate characterization of polymers under various thermal conditions.

Techniques to Enhance TGA Resolution for Complex Samples

Enhancing the resolution of TGA measurements for complex samples requires strategic adjustments to experimental conditions. Start by reducing your sample size, which minimizes thermal gradients and improves accuracy.

Optimize your heating rate by slowing it down, allowing for more precise detection of mass changes. Select purge gases like helium, known for high thermal conductivity, to boost resolution.

Use advanced sensitivity balances capable of detecting small mass variations, especially with low-mass samples. Incorporate multi-modal analysis by combining TGA with techniques like Raman spectroscopy or DSC to clarify complex thermograms.

Fine-tune temperature calibration and environmental controls, such as humidity, for consistency. Switching atmospheres between inert and reactive gases can reveal detailed decomposition pathways.

Finally, leverage ultra-fast heating systems to capture rapid thermal events with greater clarity.

Practical Tips for Accurate TGA Sample Preparation

Accurate TGA results depend heavily on proper sample preparation, as inconsistencies can lead to misleading data. Keep sample sizes between 5–10 mg for polymers to ensure representative, reproducible results, and reduce to 0.5–2 mg for TGA-MS coupling to improve sensitivity.

Avoid large samples that cause thermal gradients and uneven heating. Instead, finely grind or cut samples into small pieces for uniform heat transfer. Always dry samples thoroughly to eliminate moisture, which can cause early weight loss.

Use inert, clean sample holders like platinum or alumina pans, and handle samples with gloves to prevent contamination. Ensure consistent placement and mass across runs.

Proper preparation minimizes artifacts, improves accuracy, and enhances the reliability of your thermal analysis.

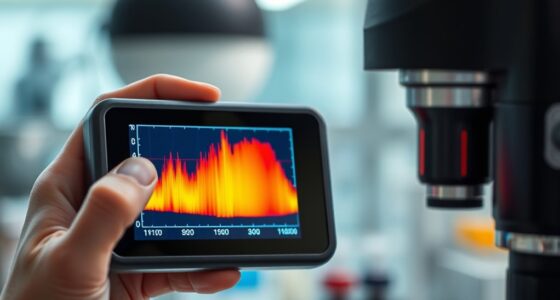

Combining TGA With Other Analytical Methods for Comprehensive Polymer Insights

Combining TGA with other analytical techniques provides a more extensive view of polymer behavior by integrating different types of data. For example, pairing TGA with Differential Scanning Calorimetry (DSC) helps you distinguish physical transitions like melting from chemical degradation, giving insights into thermal and oxidative stability.

TGA-FTIR reveals the chemical nature of gases evolved during decomposition, identifying degradation mechanisms and functional groups. TGA-MS offers molecular details of volatile fragments, clarifying degradation pathways and compositional differences.

Combining TGA with microscopy links thermal stability to structural and morphological changes, such as cracking or phase separation. Integrating TGA with rheological or mechanical tests further relates thermal stability to material performance, providing a thorough understanding of polymer properties under various conditions.

Frequently Asked Questions

How Does TGA Distinguish Between Overlapping Decomposition Processes?

You look at how different decomposition events overlap by analyzing the mass loss patterns and their temperature ranges. Using multiple heating rates shifts these events apart, making them easier to distinguish.

Derivative curves (DTG) highlight individual peaks, and software tools help deconvolute overlapping signals.

Combining techniques like DSC or changing atmospheres further clarifies the separate processes, allowing you to identify each component’s decomposition behavior accurately.

Can TGA Analyze Extremely Small or Thin Polymer Samples Effectively?

You might wonder if TGA can analyze tiny or thin samples effectively. It depends on the instrument’s sensitivity and proper sample preparation. High-sensitivity TGA devices can detect small mass changes, but noise and sampling errors can pose challenges.

To improve accuracy, combining TGA with techniques like mass spectrometry or using advanced instruments helps you get reliable data from small or thin samples, ensuring precise analysis despite size limitations.

What Are the Best Practices for Calibrating a TGA Instrument?

To calibrate your TGA accurately, you should perform daily checks, especially after changing temperature ranges, purge gases, or moving the instrument.

Use standard materials like melting point or Curie temperature standards, and make certain calibration software is properly set.

Always verify thermal contact, optimize sample mass, and maintain consistent environmental conditions.

Regular calibration within ±2 °C to 5 °C guarantees precise measurements and reliable results.

How Does Atmosphere Composition Influence TGA Results?

So, you think atmosphere composition doesn’t matter? Think again! It dramatically influences your results—oxidative atmospheres make your polymer burn like a campfire, revealing combustion behavior, while inert gases keep things calm, showing pure decomposition.

The atmosphere shapes weight loss, stability insights, and residue. Change the gas, change the story your data tells.

Choose wisely; your polymer’s secrets depend on it!

Is TGA Suitable for Analyzing Highly Cross-Linked or Insoluble Polymers?

You’ll find TGA suitable for analyzing highly cross-linked or insoluble polymers because it measures mass loss directly, regardless of solubility. It’s effective in evaluating thermal stability and degradation temperatures, even for insoluble samples.

While complex degradation steps may occur, combining TGA with other techniques like FTIR or MS can clarify mechanisms. Overall, TGA provides valuable insights into the thermal behavior of these stable, cross-linked materials.

Conclusion

Think of TGA as your trusted microscope for polymers, revealing their secrets one weight loss step at a time. By understanding its principles, applications, and limitations, you can unveil detailed insights into polymer composition, stability, and degradation. When you use TGA wisely, it’s like having a detective’s magnifying glass—helping you solve complex material mysteries efficiently. Embrace this technique, and your polymer analysis will become clearer and more precise.