To understand the silicon revolution, you need to know how chemists develop photoresists—light-sensitive materials that create tiny, precise patterns in electronics manufacturing. These chemists design special molecules that change solubility when exposed to light, enabling the production of complex circuits. Their innovations support shrinking device sizes and advanced lithography techniques like EUV. Exploring this further reveals how chemistry drives miniaturization and technological progress, shaping the future of electronics—so keep exploring to learn more.

Key Takeaways

- Chemists develop light-sensitive chemical formulations that enable precise patterning essential for silicon chip miniaturization.

- Advances in photoresist chemistry support the evolution of lithography techniques like EUV, driving smaller transistor sizes.

- Photoresist innovations enable higher resolution, better adhesion, and increased resistance, critical for manufacturing complex silicon circuits.

- Collaboration between chemical engineers and lithography experts accelerates the creation of materials for faster, more efficient semiconductor production.

- Ongoing research in photoresist chemistry underpins the silicon revolution by facilitating the continuous scaling of electronic devices.

Photoresists are essential materials in the manufacturing of electronic devices, serving as the light-sensitive layers that define intricate circuit patterns. Without them, creating the tiny, precise features on chips would be impossible. As you explore how these materials come to be, you’ll see that their development hinges on a blend of lithography innovation and chemical engineering. Chemists play a crucial role in pushing the boundaries of what’s possible, continuously improving photoresists to meet the demanding needs of modern electronics.

Photoresists are vital light-sensitive materials shaping modern electronic device manufacturing.

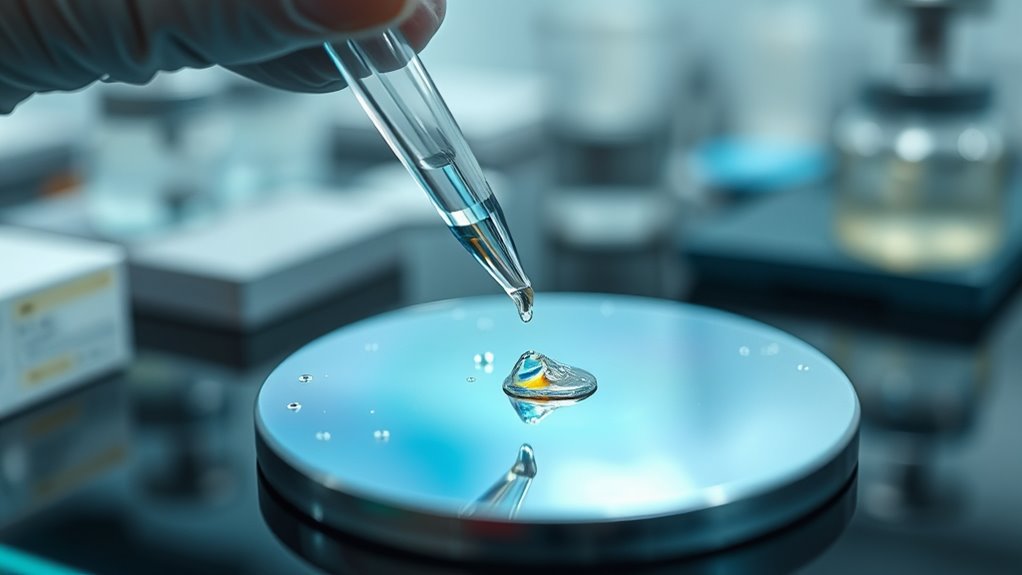

In the realm of lithography, every nanometer counts. Chemists develop photoresist formulations that respond precisely to specific wavelengths of light, allowing for finer patterning. This involves meticulous chemical engineering—designing molecules that change solubility or become insoluble when exposed to light. These innovations drive the evolution of lithography techniques, enabling semiconductor manufacturers to produce ever-smaller transistors and more powerful chips. You might not realize it, but every breakthrough in photoresist chemistry unlocks new levels of device performance and miniaturization.

Chemical engineering is at the heart of creating photoresists that are both highly sensitive and resistant to harsh processing conditions. Chemists work to balance the formulation so that the resist can be applied uniformly, develop sharp edges, and withstand etching processes without degrading. Innovations in polymer science, photoactive compounds, and additives have allowed chemists to tailor properties like adhesion, resolution, and stability. These advancements directly influence lithography innovation, making it possible to pattern complex circuits with unparalleled accuracy. You can think of chemists as the architects of these materials, designing molecules with precision to meet the exacting standards of next-generation electronics.

As technology progresses, chemists continually refine photoresist formulations. They explore new chemical pathways, test novel compounds, and optimize processes to keep pace with the shrinking sizes of transistors. This ongoing research involves a deep understanding of chemical reactions, material interactions, and manufacturing constraints. The goal is to produce photoresists that are more environmentally friendly, cost-effective, and capable of supporting emerging lithography techniques such as extreme ultraviolet (EUV) lithography. You benefit from these innovations as they enable faster, more efficient production of advanced devices.

Furthermore, advances in photoresist materials are driven by the need to accommodate new lithography techniques like EUV, which require even more precise and resistant formulations. This ongoing research involves a deep understanding of chemical reactions, material interactions, and manufacturing constraints. The collaboration between lithography innovation and chemical engineering shapes the future of electronics manufacturing. Chemists, with their expertise in designing and synthesizing specialized chemicals, ensure that photoresists keep evolving. Their work allows you to enjoy increasingly powerful, compact devices—proof that behind every sleek smartphone or high-performance computer lies the vital chemistry of photoresists. This ongoing synergy is what drives the silicon revolution forward, making the impossible possible in the world of microelectronics.

Frequently Asked Questions

How Do Photoresists Impact the Overall Cost of Semiconductor Manufacturing?

Photoresists substantially impact your semiconductor manufacturing costs by enabling cost reduction through precise patterning, which minimizes waste and rework. Their quality and availability influence your supply chain, affecting overall expenses. When you choose advanced photoresists, you often benefit from improved efficiency, reducing production time and costs. However, high-quality materials can raise upfront expenses, but overall, optimizing photoresist use streamlines your process and lowers long-term manufacturing costs.

What Are the Latest Innovations in Photoresist Materials?

You’ll find that the latest innovations in photoresist materials focus on enhancing durability and precision for advanced techniques like nanoimprint lithography. New formulations improve photoresist durability, enabling finer features and better resistance during processing. These developments help you achieve higher resolution and more reliable manufacturing, pushing the boundaries of semiconductor technology. As a result, your production becomes more efficient, cost-effective, and capable of supporting next-generation device fabrication.

How Do Chemists Develop Environmentally Friendly Photoresists?

Chemists develop environmentally friendly photoresists by applying green chemistry principles, such as using biodegradable materials and reducing hazardous solvents. They focus on sustainable practices like designing photoresists that emit fewer volatile organic compounds and utilizing renewable resources. By innovating with water-based formulations and minimizing waste, you help create eco-friendly options that maintain performance while safeguarding the environment. This approach ensures safer manufacturing and disposal processes for the future.

What Challenges Do Chemists Face in Improving Photoresist Resolution?

You face significant challenges in improving photoresist resolution, mainly dealing with alignment issues and material stability. As feature sizes shrink, precise alignment becomes harder, risking errors in pattern transfer. Additionally, maintaining material stability during exposure and development is vital to prevent distortion or degradation. Overcoming these hurdles requires innovative formulations and advanced processing techniques to achieve higher resolution without sacrificing reliability or environmental safety.

How Does Photoresist Chemistry Influence Device Miniaturization?

You might think photoresist chemistry doesn’t impact device miniaturization, but it’s essential. Achieving molecular precision and layer uniformity allows for finer feature patterns, enabling smaller, more powerful devices. Chemists develop advanced formulations that improve resolution and resist stability, directly pushing the limits of how tiny components can be. Without these innovations, miniaturization stalls, so understanding and optimizing photoresist chemistry is critical for technological advancement.

Conclusion

So, next time you marvel at your sleek gadgets, thank the chemists behind those tiny photoresists. They’ve turned microscopic tricks into massive tech leaps, all while hiding behind beakers and fumes. Without their secret sauce, your smartphone would be as useful as a paperweight. Cheers to the unsung heroes of the silicon revolution—you know, the ones making all this possible, one tiny, mysterious chemical at a time.