If you’re looking for the best dry scroll vacuum pumps for lab use in 2026, I recommend considering models like Edwards nXDS series and GWSP models, which offer reliable, contaminant-free operation. Focus on pumps with easy-to-replace seals and filters to maintain performance and extend lifespan. Compatibility with lab applications and chemical resistance are vital. Keep an eye on features like noise levels and maintenance costs—you’ll find all the details if you explore further.

Key Takeaways

- Focus on pumps compatible with all nXDS models, offering reliable performance for lab applications like freeze drying and surface analysis.

- Prioritize units with PTFE tip seals and filter options to ensure chemical resistance and contamination control in clean environments.

- Consider pumps with easy-to-maintain seal kits and filter replacements, reducing downtime and extending lifespan.

- Evaluate noise levels, vibration, and inlet temperature limits for optimal operation in sensitive laboratory settings.

- Check warranty coverage, support options, and long-term durability features to maximize investment and system reliability.

| Dry Scroll Vacuum Pump Seal Kit for Edwards nXDS |  | Best Maintenance Kit | Compatibility: All nXDS series pumps | Operation Environment: Vacuum systems, lab use | Usage Type: Minor rebuilds | VIEW LATEST PRICE | See Our Full Breakdown |

| GWSP-150 Dry Scroll Vacuum Pump (1 Phase) |  | Versatile Lab Use | Compatibility: GWSP-150 model | Operation Environment: Clean process environments | Usage Type: Continuous operation in clean processes | VIEW LATEST PRICE | See Our Full Breakdown |

| Tip Seal Kit for Edwards ESDP 15 Vacuum Pumps |  | Cost-Effective Solution | Compatibility: Edwards ESDP series (5/15/30/60) | Operation Environment: Laboratory, scientific research, industrial | Usage Type: Routine maintenance, seal replacement | VIEW LATEST PRICE | See Our Full Breakdown |

| Dry Scroll Pump Seal Kit for Edwards nXDS Pumps |  | Trusted Performance | Compatibility: All nXDS series pumps | Operation Environment: Vacuum applications, lab use | Usage Type: Minor rebuilds, maintenance | VIEW LATEST PRICE | See Our Full Breakdown |

| Edwards XDS35i Dry Scroll Vacuum Pump Filter |  | Inlet/Exhaust Protection | Compatibility: Edwards XDS35i | Operation Environment: Laboratory, industrial systems | Usage Type: Filtration, system protection | VIEW LATEST PRICE | See Our Full Breakdown |

| GWSP-1000 Dry Scroll Vacuum Pump (1 Phase) |  | High-Precision Pump | Compatibility: GWSP-1000 model | Operation Environment: Clean process environments | Usage Type: Precise vacuum processes | VIEW LATEST PRICE | See Our Full Breakdown |

| Tip Seal Replacement Set for Edwards nXDS6i Vacuum Pumps |  | Reliable Replacement | Compatibility: Edwards nXDS6i, 10i, 15i, 20i, XDS5, 10, 35i, 46i | Operation Environment: Laboratory, scientific research, industrial | Usage Type: Routine maintenance, seal replacement | VIEW LATEST PRICE | See Our Full Breakdown |

| GWSP-600 Dry Scroll Vacuum Pump (1 Phase) |  | Heavy-Duty Model | Compatibility: GWSP-600 model | Operation Environment: Clean process environments | Usage Type: Regular operation in clean environments | VIEW LATEST PRICE | See Our Full Breakdown |

More Details on Our Top Picks

Dry Scroll Vacuum Pump Seal Kit for Edwards nXDS

The Dry Scroll Vacuum Pump Seal Kit for Edwards nXDS is an essential solution for laboratories that rely on maintaining consistent, high-performance vacuum systems. I recommend this kit for minor rebuilds to restore best pump function. Designed for all nXDS models, it helps address seal wear, which can cause increased base pressure and reduced vacuum quality. Typically, seals should be replaced every 12,000 to 16,000 hours or about two years. Regular maintenance with this kit ensures the pump maintains low ultimate pressures, keeps vacuum integrity intact, and extends the pump’s lifespan. It’s a simple, effective way to keep your system running smoothly.

- Compatibility:All nXDS series pumps

- Operation Environment:Vacuum systems, lab use

- Usage Type:Minor rebuilds

- Material:Not specified

- Filter Compatibility:Not specified

- Power Source:Not specified

- Additional Feature:Suitable for minor rebuilds

- Additional Feature:Restores vacuum performance

- Additional Feature:Compatible with all nXDS models

GWSP-150 Dry Scroll Vacuum Pump (1 Phase)

If you’re working in a clean process environment and need reliable vacuum performance, the GWSP-150 Dry Scroll Vacuum Pump (1 Phase) is an excellent choice. Designed specifically for applications like freeze drying, distillation, and coating, it guarantees contaminant-free operation. Its single-phase motor simplifies setup and reduces maintenance. The pump handles various delicate processes, including lithium-ion battery production and surface analysis, without introducing oils or lubricants. Remember, it’s only suitable for clean gases and shouldn’t be used with hazardous or corrosive substances. With its robust design and versatility, the GWSP-150 helps maintain ideal vacuum performance in sensitive laboratory environments.

- Compatibility:GWSP-150 model

- Operation Environment:Clean process environments

- Usage Type:Continuous operation in clean processes

- Material:Not specified

- Filter Compatibility:Not specified

- Power Source:Not specified

- Additional Feature:Designed for clean processes

- Additional Feature:Not for hazardous gases

- Additional Feature:Operation in controlled environments

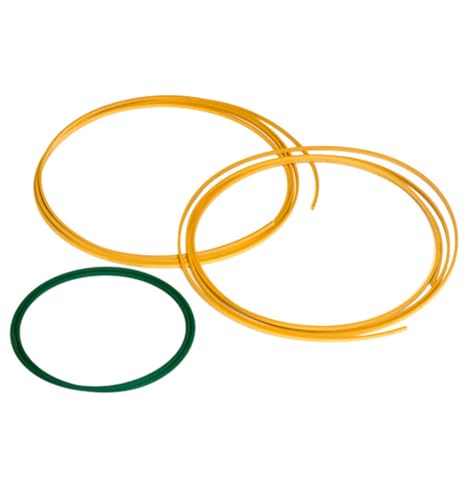

Tip Seal Kit for Edwards ESDP 15 Vacuum Pumps

For laboratories and research facilities seeking reliable, long-lasting maintenance solutions, the Tip Seal Kit for Edwards ESDP 15 vacuum pumps offers an excellent choice. Crafted from premium PTFE with a foam-back design, these seals resist wear, high temperatures, and chemicals, ensuring over a year of dependable operation. They’re easy to install, taking less than half an hour, and fit seamlessly into scroll grooves to prevent leaks and seizures. This cost-effective alternative maintains the pump’s performance, reduces noise, and supports consistent vacuum conditions. With a 12-month warranty and included storage box, it’s a smart investment for ongoing equipment reliability.

- Compatibility:Edwards ESDP series (5/15/30/60)

- Operation Environment:Laboratory, scientific research, industrial

- Usage Type:Routine maintenance, seal replacement

- Material:PTFE (Teflon)

- Filter Compatibility:Not specified

- Power Source:Not specified

- Additional Feature:Constructed from PTFE (Teflon)

- Additional Feature:Easy installation process

- Additional Feature:12-month warranty included

Dry Scroll Pump Seal Kit for Edwards nXDS Pumps

Choosing the right seal kit is essential for maintaining peak performance in Edwards nXDS dry scroll pumps, especially when minor rebuilds are needed. The Dry Scroll Pump Seal Kit for Edwards nXDS (PN: A735-01-801) is designed for this purpose, compatible with all nXDS series models. Over time, tip seals wear out, causing an increase in base pressure from below 10 mTorr to around 25 mTorr. Replacing these seals restores ideal vacuum performance, ensuring the pump continues to operate efficiently. Regular inspections of the base pressure help determine when seals need replacing, preventing performance declines and maintaining reliable, leak-tight operation.

- Compatibility:All nXDS series pumps

- Operation Environment:Vacuum applications, lab use

- Usage Type:Minor rebuilds, maintenance

- Material:Not specified

- Filter Compatibility:Not specified

- Power Source:Not specified

- Additional Feature:Maintains low base pressure

- Additional Feature:Replaces tips every 12,000-16,000 hours

- Additional Feature:Designed for all nXDS series

Edwards XDS35i Dry Scroll Vacuum Pump Filter

The Edwards XDS35i Dry Scroll Vacuum Pump Filter stands out as an essential accessory for laboratory environments that demand reliable protection against dust and particulate contamination. Designed specifically for the XDS35i dry scroll pumps, this KF-40 inlet or exhaust filter prevents dust migration into the system, helping maintain peak performance. It comes ready to use with a 5-micron filter element and offers versatile installation options—either between the pump inlet and chamber or at the exhaust. An NW40 hose nozzle simplifies connection, and replacement filters are available in 1- and 5-micron options, ensuring long-term system cleanliness and pump protection.

- Compatibility:Edwards XDS35i

- Operation Environment:Laboratory, industrial systems

- Usage Type:Filtration, system protection

- Material:Not specified

- Filter Compatibility:Yes (inlet/exhaust filters)

- Power Source:Not specified

- Additional Feature:Inlet or exhaust filtration

- Additional Feature:Ready-to-use 5-micron filter

- Additional Feature:Compatible with KF-40 fittings

GWSP-1000 Dry Scroll Vacuum Pump (1 Phase)

If you’re seeking a reliable vacuum solution for precise laboratory applications, the GWSP-1000 Dry Scroll Vacuum Pump (1 Phase) stands out as an excellent choice. It’s designed for clean, accurate vacuum processes like freeze drying, distillation, and coating techniques. Made from stainless steel, it’s built for durability and easy integration into lab setups. The pump is ideal for applications such as electron microscopy, spectroscopy, and space environment simulations. Remember, it’s only suitable for non-hazardous, clean gases. With support from Avcray Style and a 30-day return policy, this pump offers both performance and peace of mind for your research needs.

- Compatibility:GWSP-1000 model

- Operation Environment:Clean process environments

- Usage Type:Precise vacuum processes

- Material:Stainless steel

- Filter Compatibility:Not specified

- Power Source:Corded electric

- Additional Feature:Made from stainless steel

- Additional Feature:Supports numerous lab applications

- Additional Feature:30-day return policy

Tip Seal Replacement Set for Edwards nXDS6i Vacuum Pumps

For laboratories seeking reliable and cost-effective maintenance solutions, the Tip Seal Replacement Set for Edwards nXDS6i vacuum pumps offers an excellent choice. This set includes two durable, imported PTFE tip seals designed to fit models like nXDS6i, 10i, 15i, and others in the series. They provide low wear, high-temperature tolerance, and chemical resistance, ensuring long-lasting, quiet operation. The straightforward installation takes less than half an hour, and the cost savings compared to genuine parts make routine maintenance more affordable. With a 12-month guarantee, this kit helps keep your vacuum pump running smoothly, preventing leaks and ensuring peak performance.

- Compatibility:Edwards nXDS6i, 10i, 15i, 20i, XDS5, 10, 35i, 46i

- Operation Environment:Laboratory, scientific research, industrial

- Usage Type:Routine maintenance, seal replacement

- Material:PTFE (Teflon)

- Filter Compatibility:Not specified

- Power Source:Not specified

- Additional Feature:Cost-effective maintenance

- Additional Feature:Suitable for multiple nXDS models

- Additional Feature:Easy, quick replacement process

GWSP-600 Dry Scroll Vacuum Pump (1 Phase)

Designed specifically for clean processes, the GWSP-600 Dry Scroll Vacuum Pump (1 Phase) offers a contaminant-free environment ideal for laboratory applications. It’s perfect for situations where purity matters, as it doesn’t require oil or lubricants that could introduce contaminants. However, it’s not suitable for pumping toxic, explosive, flammable, or corrosive gases, or materials containing chemicals or particles. To guarantee safety and proper operation, the inlet gas temperature should stay below 122°F. Routine maintenance should only be performed on pumps used with safe, non-hazardous substances. For detailed specs, always consult the official documentation.

- Compatibility:GWSP-600 model

- Operation Environment:Clean process environments

- Usage Type:Regular operation in clean environments

- Material:Stainless steel

- Filter Compatibility:Not specified

- Power Source:Not specified

- Additional Feature:Designed for contaminant-free environments

- Additional Feature:Not for hazardous gases

- Additional Feature:Safe operation below 122°F inlet temperature

Factors to Consider When Choosing a Dry Scroll Vacuum Pump for Lab

When selecting a dry scroll vacuum pump for your lab, it’s important to take into account how well it matches your specific applications. You also want a model that’s durable, easy to maintain, and resistant to chemicals you work with. Additionally, factors like noise levels, vibration, price, and warranty can influence your decision considerably.

Compatibility With Applications

Choosing a dry scroll vacuum pump that fits your lab’s specific application is essential for peak performance. I recommend verifying that the pump is suitable for your particular process, whether it’s freeze drying, coating, or electron microscopy. Check that the materials used in construction and sealing are compatible with the chemicals or particles involved, preventing corrosion or contamination. Make sure the pump’s maximum inlet gas temperature and pressure match your operational needs to avoid damage or inefficiency. Ensure it supports the necessary inlet and exhaust filters to keep your system clean. Additionally, consider the pump’s size, power requirements, and maintenance intervals to ensure they align with your workflow and lab environment. This careful matching guarantees optimal results and system longevity.

Maintenance and Durability

Regular maintenance is essential for ensuring your dry scroll vacuum pump performs reliably over time. Timely seal replacements prevent performance drops and extend the pump’s lifespan. The durability of tip seals depends on material quality and operating conditions; high-quality PTFE seals can last over a year with proper care. Following recommended service intervals, typically between 12,000 and 16,000 hours, helps maintain ideal performance. Choosing seals and components designed for high extrusion resistance and temperature tolerance boosts reliability and reduces repairs. Regular inspection of the base pressure and overall system integrity allows early detection of seal wear, avoiding costly repairs and downtime. Proper handling and scheduled maintenance are key to maximizing the durability and efficiency of your dry scroll vacuum pump in a lab setting.

Chemical Resistance Features

The materials used in dry scroll vacuum pumps directly impact their ability to withstand aggressive chemicals often encountered in laboratory settings. Seals, gaskets, and internal components made from PTFE or stainless steel offer high chemical resistance, enabling the pump to handle reactive vapors without degradation. This resistance is vital for pumping process gases that contain solvents, acids, or other corrosive substances, preventing leaks, contamination, and pump failure. Choosing pumps with robust chemical-resistant materials guarantees longer service life and consistent performance over time. Regularly evaluating chemical compatibility is essential to avoid material breakdown and maintain operational integrity, especially during prolonged use with aggressive chemicals. Prioritizing these features helps ensure the pump’s durability and reliable operation in demanding laboratory environments.

Noise and Vibration Levels

When selecting a dry scroll vacuum pump for lab use, considering noise and vibration levels is essential because they directly impact workspace comfort and equipment stability. Lower noise levels, typically between 50 and 70 decibels, help maintain a quieter environment, reducing distractions. Vibration is usually minimal—below 5 mm/s—which supports system stability and extends pump lifespan. Proper alignment and high-quality materials are key factors in minimizing noise and vibration during operation. Some pumps feature advanced damping or sound insulation, further decreasing noise emissions. Excessive noise or vibrations can signal seal wear or misalignment, indicating the need for maintenance. Choosing a pump with optimized noise and vibration characteristics ensures smoother operation, a more comfortable lab environment, and reliable performance over time.

Price and Warranty Options

Are you getting the best value for your investment in a dry scroll vacuum pump? It’s vital to consider both price and warranty options. Check if the listed price includes essential components like filters or seal kits, which can add to upfront costs later. Compare prices across online and offline stores, and look for discounts or price-match guarantees. Evaluate the warranty duration—some brands offer 12 months of support, giving you peace of mind. Review the manufacturer’s support policies, especially whether maintenance or replacement parts are covered. Pay close attention to warranty terms, ensuring they specify conditions for repairs or replacements, particularly for critical parts like seals. Making an informed choice now can save you money and hassle down the line.

Frequently Asked Questions

How Do Dry Scroll Vacuum Pumps Compare to Other Pump Types?

Dry scroll vacuum pumps are highly efficient and reliable compared to other pump types. They operate without oil, reducing contamination risks and maintenance. I find them quieter and more energy-efficient than rotary vane or turbomolecular pumps, making them ideal for lab environments. While they might have a higher upfront cost, their durability and low upkeep often save money long-term. Overall, I prefer dry scroll pumps for their cleanliness and consistent performance.

What Maintenance Is Required for Dry Scroll Vacuum Pumps?

I check the filters regularly to keep debris out, and I make sure the pump oil is clean and at the right level. I also inspect seals for wear and replace them if needed to prevent leaks. Additionally, I run the pump periodically to keep components lubricated and functioning smoothly. Doing these simple maintenance steps helps me maintain peak performance and extends the lifespan of my dry scroll vacuum pump.

Can Dry Scroll Pumps Operate Continuously Without Overheating?

Yes, dry scroll pumps can operate continuously without overheating, but it depends on proper design and maintenance. I always make certain they have adequate cooling systems and are kept clean to prevent heat buildup. Regularly monitoring temperature and airflow is vital. When well-maintained, they handle continuous operation efficiently, making them reliable for lab use. Just remember, proper cooling and maintenance are key to preventing overheating during long-term operation.

What Is the Typical Lifespan of a Dry Scroll Vacuum Pump?

Imagine a vintage clock—reliable and enduring. That’s how I see the typical lifespan of a dry scroll vacuum pump. Usually, it lasts between 5 to 10 years with proper maintenance. Factors like operating conditions, regular servicing, and quality influence longevity. I always recommend routine checks to maximize your pump’s life, ensuring it keeps working smoothly, much like a timeless piece of engineering.

Are Dry Scroll Vacuum Pumps Suitable for High-Vacuum Applications?

Yes, dry scroll vacuum pumps are suitable for high-vacuum applications. I’ve found they excel at achieving deep vacuum levels efficiently without oil contamination, making them ideal for sensitive lab work. Their continuous operation and low maintenance also help maintain consistent high-vacuum conditions. Just guarantee you select a model designed for the specific vacuum range you need, and you’ll find them highly effective for demanding applications.

Conclusion

Choosing the right dry scroll vacuum pump is essential for lab efficiency. Did you know that dry scroll pumps can reduce maintenance costs by up to 30% compared to traditional models? Whether you need a compact GWSP-150 or a powerful GWSP-1000, selecting the right seal kits and filters guarantees peak performance. Investing wisely in these pumps not only boosts your lab’s productivity but also saves you money in the long run.