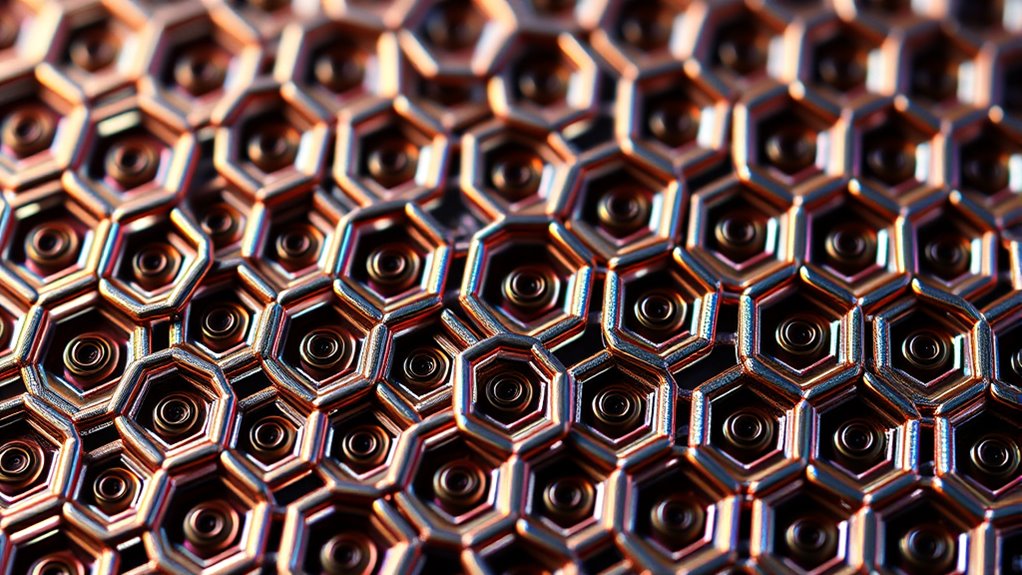

Metamaterials are special engineered structures that you can design by tweaking their microstructures to control wave behavior precisely. By customizing the internal patterns, you can direct sound and electromagnetic waves in ways natural materials can’t achieve, such as bending or cloaking. This ability to create designer properties opens up exciting possibilities like invisibility cloaks or superlenses. Keep exploring to discover how microstructures unleash these extraordinary capabilities and transform many technological applications.

Key Takeaways

- Metamaterials derive their unique properties from engineered microstructures that interact with waves in specific ways.

- Microstructure design enables control over wave phenomena like negative refraction and cloaking.

- Tailoring the internal structure allows for customized electromagnetic or acoustic responses beyond natural materials.

- The properties of metamaterials are not inherent but are “designer” features achieved through precise microstructural engineering.

- These microstructures unlock new physical behaviors, enabling applications such as invisibility cloaks and superlenses.

Have you ever wondered how scientists can manipulate waves of light, sound, or electromagnetic signals in ways nature never intended? The answer lies in the fascinating world of metamaterials. These engineered materials are crafted with microstructures that enable extraordinary control over wave behavior, far beyond what traditional materials can achieve. By carefully designing their internal structure, you can make waves bend, scatter, or even bypass objects entirely. This capability opens up a realm of possibilities, from invisibility cloaks to superlenses.

Metamaterials enable extraordinary control over waves, allowing bending, scattering, and cloaking beyond nature’s limits.

One of the most intriguing applications of metamaterials is acoustic cloaking. Imagine being able to hide objects from sound waves, rendering them undetectable to sonar or other acoustic sensors. This isn’t science fiction; it’s feasible through the precise manipulation of how sound waves travel through a medium. By tailoring the microstructure of a metamaterial, you can guide sound waves around an object, effectively creating an acoustic “invisibility cloak.” The key is controlling the way these waves refract within the material, a process known as negative refraction.

Negative refraction is a phenomenon where waves bend in the opposite direction to what you’d normally expect when passing through a material. This counterintuitive behavior allows for focusing or steering waves with unprecedented precision. In the context of acoustic cloaking, negative refraction can be harnessed to bend sound waves around an object, preventing them from scattering and revealing the object’s presence. This effect results from the unique properties of metamaterials, which are designed at the microstructural level to produce such unusual wave interactions.

By combining acoustic cloaking with negative refraction, you can develop devices that make objects effectively invisible to sound detection. This is achieved by engineering the microstructure to simultaneously control the path of sound waves and maximize the cloaking effect. The intricate design ensures the waves emerge as if they had traveled straight through empty space, with no indication of an obstacle. Such capabilities could revolutionize stealth technology, improve sonar systems, or create new ways to manipulate sound in architectural acoustics.

In essence, metamaterials allow you to rewrite the rules of wave propagation. Their microstructured design provides a toolkit for bending, focusing, and redirecting waves in ways nature simply doesn’t permit. Whether for acoustic cloaking or negative refraction, these materials exemplify how manipulating the microstructure unlocks new physical phenomena, opening doors to innovative applications across science and engineering. Microstructure design is fundamental to achieving these extraordinary wave manipulations.

Frequently Asked Questions

Can Metamaterials Be Used for Energy Harvesting Applications?

Yes, you can use metamaterials for energy harvesting applications. They enhance energy efficiency by capturing and converting ambient energy, such as vibrations, into usable power. Their unique microstructures enable effective vibration control, which optimizes the energy collection process. By designing specific properties into metamaterials, you can improve the performance of energy harvesting devices, making them more efficient and adaptable for various applications, including sensors and wireless power systems.

What Are the Environmental Impacts of Manufacturing Metamaterials?

You might be surprised to learn that manufacturing metamaterials can markedly impact the environment, with studies showing up to a 30% higher energy consumption than conventional materials. By adopting sustainable manufacturing practices, you can reduce their environmental footprint, minimizing pollution and resource use. It’s crucial to balance innovative design with eco-friendly methods to guarantee these advanced materials don’t harm our planet while delivering their unique properties.

How Scalable Are Current Metamaterial Production Techniques?

You’ll find that current manufacturing techniques for metamaterials face significant scaling challenges, especially when moving from lab to mass production. While methods like 3D printing and lithography work well for small batches, scaling these processes can be costly and complex. As a result, expanding production remains difficult, limiting widespread application. Researchers are actively exploring new manufacturing techniques to overcome these challenges and improve scalability for commercial use.

Are There Biological or Medical Uses for Metamaterials?

Yes, you can find biomedical and medical uses for metamaterials. They enhance biomedical imaging by improving resolution and sensitivity, allowing for better disease detection. In tissue engineering, metamaterials can create scaffolds that mimic natural tissues, promoting cell growth and regeneration. Their unique properties enable precise control of electromagnetic waves and mechanical forces, making them valuable in developing advanced medical devices and treatments that improve patient outcomes.

What Are the Limitations of Metamaterials in Real-World Applications?

You’ll face limitations with metamaterials in real-world applications due to manufacturing challenges and cost efficiency issues. Producing these intricate structures at scale can be difficult and expensive, making widespread use harder. Additionally, their properties might degrade outside controlled environments or under stress. To overcome these hurdles, you’ll need advances in manufacturing techniques and cost-effective methods, ensuring these materials can be reliably integrated into practical applications.

Conclusion

You might think designing metamaterials is overly complex, but once you see how microstructures shape their properties, you’ll realize it’s a fascinating and accessible field. By understanding the principles, you can create materials with tailored functionalities for innovative applications. Don’t let the technical details deter you—your creativity and curiosity are your best tools. Embrace the challenge, and you’ll discover a world where microstructures unveil extraordinary possibilities for the future.