To understand a P&ID and PFD, start by familiarizing yourself with their standardized symbols, which indicate equipment, valves, and instruments. Follow the flow lines and arrows to trace how fluids move through the system, paying attention to flow directions. Begin at the source point and work through each process step to see how components interact. If you keep exploring these elements, you’ll disentangle a clear picture of the entire process.

Key Takeaways

- Start by reviewing the legend to understand symbols for equipment, valves, and instruments.

- Trace flow paths using arrows to follow material movement through the process.

- Identify process stages by locating initial points like feed inlets and following sequential equipment.

- Observe relationships between symbols and flow direction to understand control points and flow diversion.

- Use standardized symbols for consistent interpretation across P&ID and PFD diagrams.

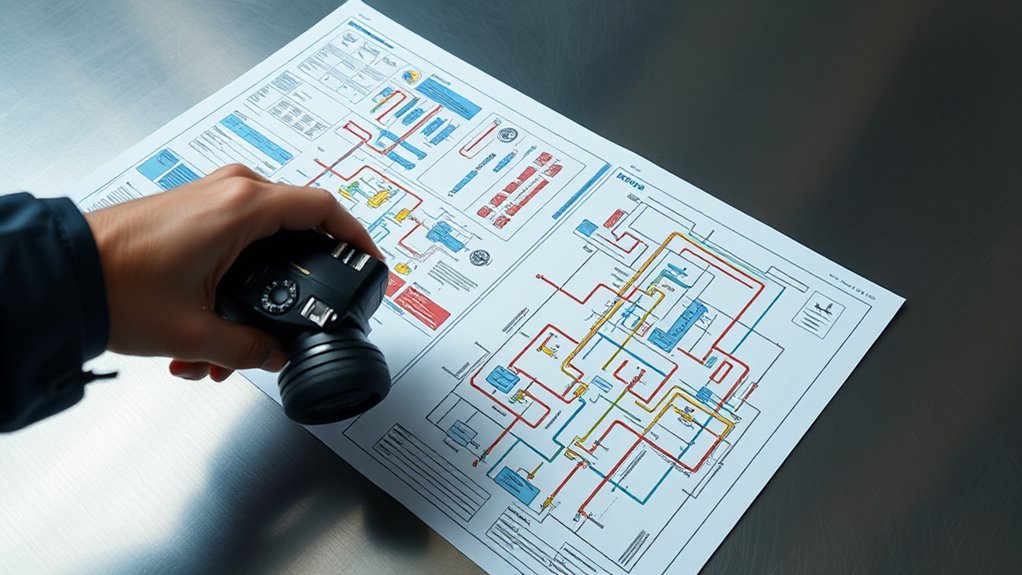

Have you ever wondered how engineers communicate complex process information effectively? When you look at a P&ID (Piping and Instrument Diagram), you’re seeing a detailed map of a process system that uses standardized symbols and conventions. One of the first things to understand is the importance of symbol legends. These legends act as a key, explaining what each symbol represents—valves, pumps, instruments, and piping components. Without knowing the symbols, deciphering a P&ID becomes nearly impossible. The legend guarantees you can quickly identify equipment and understand their functions within the process.

Flow directions are equally critical. On a P&ID, you’ll notice arrows or lines indicating the flow of fluids through pipes. These flow directions tell you how materials move from one point to another, which is essential for understanding the process’s sequence and operation. Pay close attention to these arrows; they often help you visualize the process flow, identify potential bottlenecks, and understand how different components interact. Sometimes, flow directions are marked with specific symbols or annotations, especially in complex systems, so always check the legend to confirm their meaning.

When you start reading a P&ID, begin by locating the process flow path. Follow the arrows from the initial point—like a feed inlet or a raw material source—through various equipment, valves, and instruments. Notice how the symbols are arranged and how the flow moves through different stages. This step-by-step approach helps you understand the process sequence clearly. Keep in mind that the symbols are standardized, so once you recognize them, you can interpret any P&ID with confidence, regardless of the specific system.

Another key aspect is understanding the relationship between symbols and flow directions. For example, a valve symbol might be connected with a line carrying flow, and the flow direction arrow shows whether the valve is upstream or downstream. Recognizing these relationships helps you troubleshoot or modify the process. You can quickly see where control points are located and how fluids are diverted or controlled throughout the system.

Frequently Asked Questions

What Are the Common Symbols Used in P&Id and PFD Diagrams?

You’ll notice common symbols like arrows indicating flow direction and various shapes representing process instrumentation, such as sensors, valves, and controllers. P&ID and PFD diagrams use standardized symbols to show the flow path and control devices within a process. Recognizing these symbols helps you understand how materials move through the system and how instrumentation monitors and controls process variables effectively.

How Do I Interpret Control Valves in P&Id Diagrams?

You interpret control valves in P&ID diagrams by understanding their functions, such as regulating flow, pressure, or temperature. Look for symbols indicating control valve types and note the valve position indication, which shows whether the valve is open, closed, or partially open. This helps you determine how the control system manages process variables, enabling you to visualize how the control loop operates and maintains process stability.

What Are the Differences Between P&Id and PFD Symbols?

Think of P&ID and PFD symbols as different languages in a bustling city. P&ID symbols are detailed street signs, showing equipment and control details with precise diagram conventions. PFD symbols, like city maps, simplify processes to highlight flow paths and major equipment. You’ll see that symbol comparisons reveal P&ID’s complexity versus PFD’s clarity, helping you understand system functions at a glance and navigate diagrams with confidence.

How Can I Verify the Accuracy of a P&Id?

You can verify the accuracy of a P&ID by performing inspection techniques like cross-referencing with original documentation and comparing it to actual equipment. Check for consistency, ensure all symbols match the standard, and verify label details. Review revision history and update records to confirm they’re current. Conduct physical inspections to match the diagram with real-world setups. Documentation verification helps identify discrepancies and guarantees your P&ID reflects the true process layout.

What Safety Considerations Should I Keep in Mind When Reading P&Id?

When reading a P&ID, prioritize hazard identification to spot potential risks. Always wear appropriate personal protective equipment, like gloves and goggles, to protect yourself from chemical or mechanical hazards. Be cautious around high-pressure lines and dangerous substances, and follow safety protocols. Staying alert and understanding symbols can help you recognize hazards quickly, ensuring your safety while working with or interpreting the diagram.

Conclusion

Mastering the art of reading P&IDs and PFDs might seem intimidating, but with dedication and detail, you’ll develop a decisive understanding. Immerse yourself in diagrams diligently, decipher symbols confidently, and distinguish details carefully. By practicing precision and patience, you’ll progress from puzzled to proficient. Remember, the pathway to proficiency is paved with persistence, perception, and practice. Embrace the process, and soon, you’ll confidently control complex systems with clarity and confidence.