Photochemistry in continuous flow improves traditional methods by offering safer, more efficient, and scalable reactions. It allows you to control reaction conditions precisely, using optimized LED light sources and reactor designs that guarantee uniform exposure. These systems reduce hazards, speed up reaction times, and make scale-up easier. Combining LED optimization with smart reactor design open new possibilities for faster, safer, and more sustainable light-driven processes—if you explore further, you’ll discover how these innovations work together seamlessly.

Key Takeaways

- Continuous flow photochemistry offers improved control, safety, and scalability compared to traditional batch methods.

- Optimized LED light sources enable precise wavelength tuning, enhancing reaction efficiency and selectivity.

- Reactor design ensures uniform light distribution and effective heat management for consistent photochemical outcomes.

- Material selection and thermal control are critical for maintaining catalyst stability and preventing degradation.

- Combining optimized LEDs with advanced reactor designs accelerates reaction rates and enables seamless process scale-up.

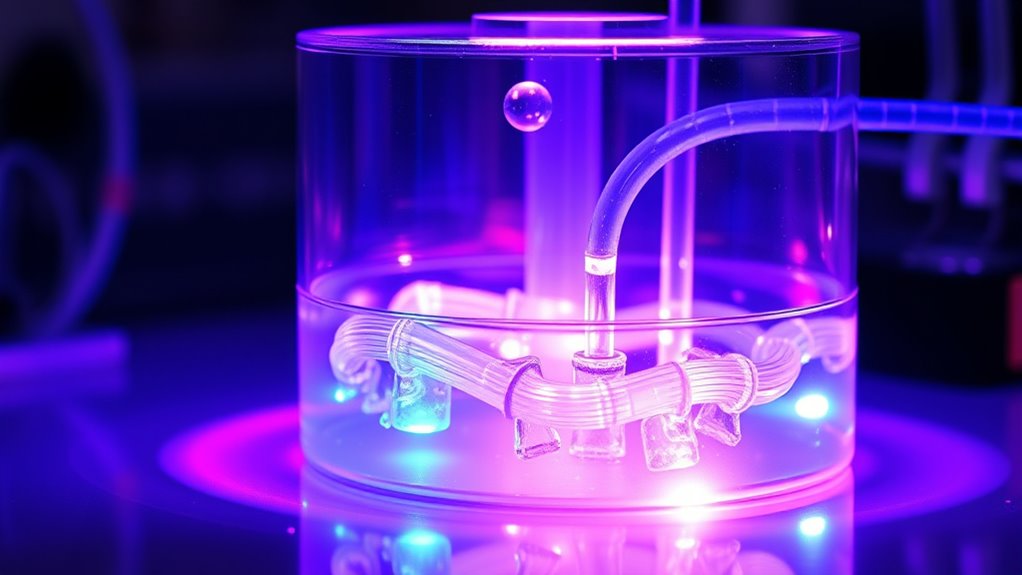

Photochemistry in continuous flow has revolutionized how you conduct light-driven chemical reactions. By shifting from traditional batch setups to continuous systems, you gain better control over reaction conditions, safety, and scalability. One of the key aspects that make this approach so effective is LED optimization. LEDs provide consistent, energy-efficient, and tunable light sources that can be finely adjusted to match the specific absorption spectra of your reactants. This precision ensures you deliver the right wavelength at the crucial intensity, which accelerates reaction rates and improves yields. When you optimize LEDs for your flow system, you minimize energy waste and reduce unwanted side reactions caused by excess heat or inappropriate wavelengths. The ability to switch wavelengths quickly also allows you to explore different reaction pathways efficiently, making your process more versatile.

Reactor design plays a fundamental role in achieving these benefits. Your reactor must facilitate uniform light distribution across the reaction mixture, which is essential for consistent results. Many designs incorporate transparent materials like quartz or specialized plastics that allow maximum light transmission while withstanding the chemical environment. You’ll want to consider the reactor’s shape and size—small, narrow channels or thin films ensure light penetrates deeply and evenly. This minimizes shadowed regions where reactions might proceed sluggishly or inconsistently. Additionally, integrating reflective surfaces or multiple LED arrays can enhance light exposure, making sure every part of your reaction mixture receives the appropriate amount of energy. Proper reactor design also helps in heat dissipation, which is crucial when working with high-intensity LEDs. Overheating can lead to degradation of sensitive reactants or catalysts, so incorporating cooling systems or selecting materials with good thermal conductivity becomes indispensable. Furthermore, color accuracy in the light source can influence the selectivity of certain photochemical reactions, making precise LED tuning even more critical.

When you combine LED optimization with thoughtful reactor design, you create a highly efficient and scalable photochemical process. This synergy allows you to perform reactions at smaller scales with high precision and then seamlessly scale up without losing control over reaction conditions. The ability to precisely control light delivery, coupled with a reactor that ensures uniform exposure, reduces reaction times and improves reproducibility. As you refine your system, you’ll find that this integrated approach not only enhances your reaction efficiency but also opens doors to new synthetic possibilities that were previously challenging or impossible with traditional methods. Overall, by focusing on LED optimization and reactor design, you’re transforming how you harness light energy to drive chemical transformations, making your processes faster, safer, and more sustainable.

Frequently Asked Questions

How Does Flow Rate Impact Photochemical Reaction Efficiency?

Your flow rate directly impacts reaction kinetics and photon flux, which in turn affect photochemical reaction efficiency. Increasing flow rate can reduce residence time, limiting photon absorption and slowing reaction speed. Conversely, a slower flow rate enhances photon flux exposure, boosting reaction efficiency. You need to optimize flow rate to balance sufficient light exposure with productive throughput, ensuring your reaction maintains high efficiency without sacrificing scalability or control.

What Are Common Challenges in Scaling up Photochemical Flow Processes?

You might think scaling up photochemical flow processes is straightforward, but equipment limitations and scaling issues can cause delays. As you increase reactor size, light penetration becomes uneven, reducing efficiency. To overcome this, you need specialized reactors designed for uniform irradiation. Addressing these challenges early helps guarantee your process remains efficient and scalable, preventing costly setbacks and optimizing your flow chemistry for larger production volumes.

How Do Light Source Choices Affect Reaction Outcomes?

Your choice of light source directly impacts reaction outcomes by affecting light wavelength and lamp intensity. Selecting the correct wavelength guarantees the reactants absorb efficiently, increasing reaction rate and selectivity. Higher lamp intensity can boost reaction speed but may also cause unwanted side reactions or degradation. Adjusting these parameters allows you to optimize conditions, improve yields, and maintain control over the photochemical process in flow systems.

Can Continuous Flow Photochemistry Be Integrated With Other Processes?

You can definitely integrate continuous flow photochemistry with other processes by designing an integrated reactor system. This approach allows you to combine photochemical steps with additional reactions, enabling efficient multi-step synthesis. By carefully coordinating the reactor design, you guarantee seamless transitions between steps, improve reaction control, and reduce processing time. Integration enhances overall efficiency, scalability, and safety, making it ideal for complex chemical syntheses in modern laboratories.

What Safety Considerations Are Unique to Photochemical Flow Reactions?

You must prioritize safety during photochemical flow reactions, as light exposure can pose serious risks. Always guarantee proper containment measures are in place to prevent accidental exposure or leaks of hazardous chemicals. Keep shielding around the reactor, use protective eyewear, and monitor the process closely. Ignoring these precautions could lead to dangerous incidents, so stay vigilant and maintain strict safety protocols to protect yourself and your environment.

Conclusion

By now, you see how continuous flow photochemistry offers faster reactions, better control, and safer processes. It’s a game-changer for scaling up and optimizing light-driven reactions. Isn’t it time you considered this approach for your projects? With its efficiency and versatility, continuous flow could transform your research or manufacturing. So, why not embrace this innovative technology and unleash new possibilities in photochemical applications today?